Millling clamps

| Windy | 06/04/2016 01:01:40 |

910 forum posts 197 photos | I require some clamping for a 8" x 9" x 5" thick 2014 aluminium I need the top to be clear to machine a flat surface I don't want to drill or put slots etc. in it for clamps yet. Have looked at T slot clamps that would put downward pressure on the edge of the block for light milling and thought about making similar type of clamps but require simple clamps as I don't want to spend too much time making tooling for a one off job. Suppose if available a cheap pair of removable vice jaws to clamp on the milling machine table would work. For a one off expensive tools or clamps are out. Suggestions of a simple clamping arrangement and maybe a drawing would be appreciated. |

| Ady1 | 06/04/2016 01:07:34 |

6137 forum posts 893 photos | The simplest I can think of is use 4 to 6 standard clamps and move them out of the way as the job progresses |

| John Stevenson | 06/04/2016 01:19:16 |

5068 forum posts 3 photos | Windy, Take a read of this post for some ideas.

|

| John Reese | 06/04/2016 04:26:38 |

1071 forum posts | About a year ago I had a similar setup problem. I found a 2 piece vise for about $44 at Enco. It was rather crudely made, but it got the job done. I don't know if Enco sells in the UK. Probably one of the European vendors handles a similar product. |

| Thor 🇳🇴 | 06/04/2016 06:31:31 |

1766 forum posts 46 photos | Hi WIndy, For clamping larger work I use these home made clamps: I clamp the work between one or two angle plates and the clamps. The photo shows one clamp dismantled. Thor |

| Sam Longley 1 | 06/04/2016 07:28:55 |

| 965 forum posts 34 photos | Could you not get 2 pieces of 1/2 inch thick bar ( could be a bit thinner) 9 inches long & pass 2 pieces of 8mm studding through them each end, each with a nut & washer on the ends, so the studding just clears the sides of the block. ( possibly have some shims to protect the side of the block from the studding threads). The bars would be on opposite sides of the stock. Then really tighten them to the block a couple of mm up from the bottom. Then use ordinary clamps to hold the 2 bars down. Or does that make the machinists on the forum cringe?? Edited By Sam Longley 1 on 06/04/2016 07:29:55 |

| JasonB | 06/04/2016 07:30:38 |

25215 forum posts 3105 photos 1 articles | Another vote for angle plate/plates

Edited By JasonB on 06/04/2016 07:35:14 |

| Windy | 06/04/2016 10:11:09 |

910 forum posts 197 photos | Thanks for the suggestions I like Thor's clamps I tried to read JS link but get This page can’t be displayed. Looking through my materials (scrap) I found some steel to make Thor's type of clamps or a crude pair of removable vice jaws. A change of tack from metal munching tonight a young friend is giving a talk about the history of the Cornet at P.E.E.M.S. club he restores vintage ones to a playable condition. There will also be a mention about ice cream ones as well. Apart from that he's a right petrol-head and has a 1970 TR6 he's restored plus he has taken me to Coniston speed week a few times to see the full size speed record boats. Likewise I've taken him to Elvington to talk to and watch the bike and car record attempt competitors. It's good to see younger generations having a practical interest in mechanical things he now has a small lathe so when time is available he can make bits for his TR.

Edited By Windy on 06/04/2016 10:12:31 |

| Russell Eberhardt | 06/04/2016 10:31:14 |

2785 forum posts 87 photos | A few ideas here. Russell. |

| Martin Connelly | 06/04/2016 10:36:30 |

2549 forum posts 235 photos | Windy, did you see the Warhorse monowheel at Elvington? I have made a lot of the parts for it. Martin |

| Windy | 06/04/2016 13:20:35 |

910 forum posts 197 photos | Got some ideas now for clamping I've seen Warhorse a few times I wonder what would happen if the rider opened the throttle two sharp would he go round in circles https://www.youtube.com/watch?v=5x597VpbjK4 As usual you start on one thread and go off at a tangent to something else Edited By Windy on 06/04/2016 13:36:41 |

| Neil Wyatt | 06/04/2016 15:57:35 |

19226 forum posts 749 photos 86 articles | I'd be more worried about locking the brakes*... one machine where being the guy who ate all the pies is a big plus Neil

(*or running out of shoe leather). Edited By Neil Wyatt on 06/04/2016 16:00:25 |

| Martin Connelly | 06/04/2016 19:13:41 |

2549 forum posts 235 photos | I was asked if I wanted to have a drive/ride, I declined the offer. Martin |

| Ian S C | 07/04/2016 12:19:34 |

7468 forum posts 230 photos | Saw a similar mono wheel on an American Auction TV show. Ian S C |

| David Colwill | 07/04/2016 13:21:46 |

| 782 forum posts 40 photos | Posted by Windy on 06/04/2016 13:20:35:

Got some ideas now for clamping I've seen Warhorse a few times I wonder what would happen if the rider opened the throttle two sharp would he go round in circles It's called gerbiling David. |

| Muzzer | 07/04/2016 14:29:35 |

2904 forum posts 448 photos | They seem to be a "look at me" machine from where I'm standing and you couldn't sensibly go anywhere on one. On that note, I'd really love to see a monowheel motorbike, rather like a conventional motorbike with only one wheel. It would take some talent to ride (someone like Rossi might manage it) although modern closed loop software and gyro / accelerometer technology would make it more manageable. I'm trying to imagine racing them... There are sort of similar things out there but they are more like a hoverboard than a motor unicycle. |

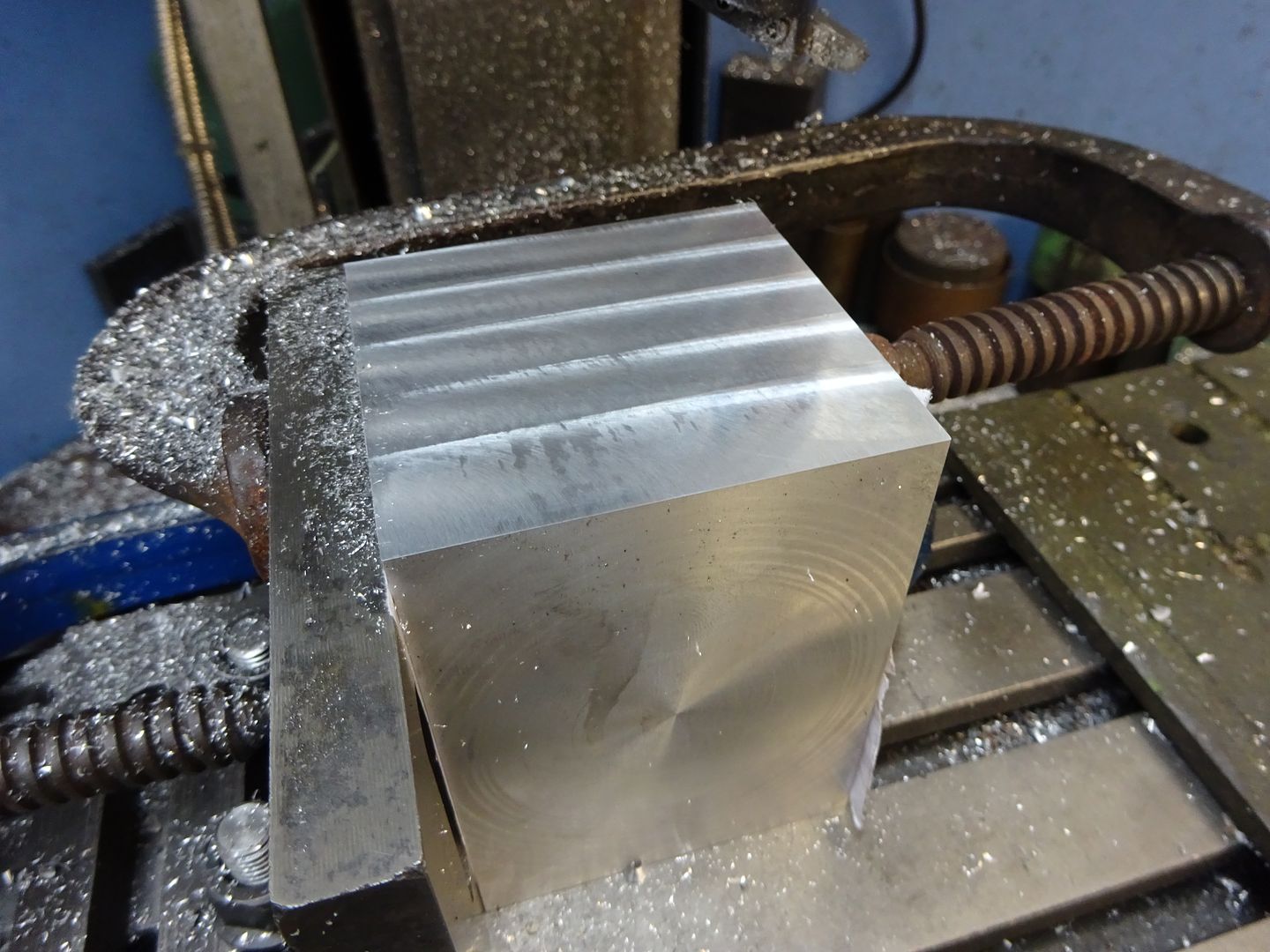

| Windy | 14/04/2016 13:51:10 |

910 forum posts 197 photos | Made some clamps and used them today holding 8" x 9" x 5" 2014 aluminium really stretching the VMC but will overcome it's limitations.

|

| mike T | 14/04/2016 14:45:27 |

| 221 forum posts 1 photos | They look to be a very sensible set of clamps you had to make. That is an enormous block of 2014, it should take you a long time to reduce that to a pile of small chips Mike |

| Windy | 14/04/2016 18:14:51 |

910 forum posts 197 photos | Posted by mike T on 14/04/2016 14:45:27:

They look to be a very sensible set of clamps you had to make. That is an enormous block of 2014, it should take you a long time to reduce that to a pile of small chips Mike I've two billets to play with to make a crankcase after seeing my friends cnc machining bigger billets for an turbine 2 wheel streamliner I think what have I let myself in for using a manual mill. But it's a challenge. Paul

|

| jimmy b | 14/04/2016 18:54:52 |

857 forum posts 45 photos | Posted by Thor on 06/04/2016 06:31:31:

Hi WIndy, For clamping larger work I use these home made clamps: I clamp the work between one or two angle plates and the clamps. The photo shows one clamp dismantled. Thor neat idea.

yet another one for the job list |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in