Old hacsaw blades

What do you do with them ?

| Speedy Builder5 | 10/11/2013 19:38:48 |

| 2878 forum posts 248 photos | I have just had a good sort out and found that I had ten or so blunt saw blades - I cried and chucked them in the bin. In the past, I have flattened tube and silver soldered a bit of blade into the tube to make workshop knives. Power hacsaw blades make good scrapers etc What do you do with them ? |

| Stub Mandrel | 10/11/2013 19:56:16 |

4318 forum posts 291 photos 1 articles | Put them in the 'I'll be glad of that when my last new one gets blunt' pile. So when the sharp one gets blunt, I have a good dozen other blunt ones to replace it with. I must face the tears and put a few in the bin. A few go into my bodge repaired stanley padsaw holder, others get used wrapped in a rag for plasterboard etc. the really crummy "I can't believe I bought these' ones do get binned, but I can't bring myself to bin Starrett or similar decent ones. Neil |

| Michael Gilligan | 10/11/2013 20:11:16 |

23121 forum posts 1360 photos | I remember my Dad grinding an excellent kitchen knife from a power hacksaw blade. He left the remains of the teeth on the sharp edge [pointing forward in the "hacksaw" direction] ... it was razor sharp, and excellent for slicing tomatoes. MichaelG. |

| DMB | 10/11/2013 20:58:39 |

| 1585 forum posts 1 photos | Modern equivalent = "kitchen devil" knife with saw teeth like a 40tpi blade. |

| I.M. OUTAHERE | 10/11/2013 21:11:21 |

| 1468 forum posts 3 photos | I made a couple of gasket scrapers by grinding one end square then bevel like a wood chisel then sharpen it , Once sharp I hone the flat side so there is no burr and this takes the edge off a little so it does not chop onto the gasket face, We used to make special knives for trimming the lead tape we used to mask jobs when I was in the Electroplating Industry.The most common was to grind at 45deg then sharpen so it was like a large craft knife , others were just like a normal knife but because they flex they were used to strip off the plastic wrap we used to mask large items . Ian |

| V8Eng | 10/11/2013 21:17:57 |

| 1826 forum posts 1 photos |

Decades ago we used to make them into a suitable blade for undercutting the insulation between commutator segments, after skimming the copper when the brushes had worn grooves into it. I guess there is not much call for that these days though!

Edited By V8Eng on 10/11/2013 21:24:48 |

| WALLACE | 10/11/2013 21:35:20 |

| 304 forum posts 17 photos | Apparently, they're quite good for grinding up and making lock picks. Allegedly. ... W. |

| Bazyle | 10/11/2013 21:50:36 |

6956 forum posts 229 photos | If you make a knife and grind the bevel on one side only it will cut right alongside a straight edge. I have left and right hand versions (somewhere) as marking out knives for woodwork. |

| julian atkins | 10/11/2013 23:02:00 |

1285 forum posts 353 photos | i save all mine. i grind off the teeth etc and use as loco leaf springs. they are more flexible than spring steel and work perfectly as leaf springs. never use tufnol strip, just eclipse blades! in fact on one of my locos with outside frames and springs above the running boards (an old GWR design) you can just see 'eclipse' in the paint if you look very closely! cheers, julian |

| Michael Gilligan | 10/11/2013 23:35:32 |

23121 forum posts 1360 photos | Posted by DMB on 10/11/2013 20:58:39:

Modern equivalent = "kitchen devil" knife with saw teeth like a 40tpi blade. . Dad's was made from a machine hacksaw blade, of about 10tpi Rigid, High Speed Steel. Not much like a "Kitchen Devil" really. MichaelG. |

| daveb | 11/11/2013 00:09:50 |

| 631 forum posts 14 photos | Posted by WALLACE on 10/11/2013 21:35:20:

Apparently, they're quite good for grinding up and making lock picks. Allegedly. ... W. No, the HSS ones are to brittle, the cheap ones are too soft. Metal baling band was OK, also bandsaw blade.

So I'm told................................

|

| _Paul_ | 11/11/2013 01:05:59 |

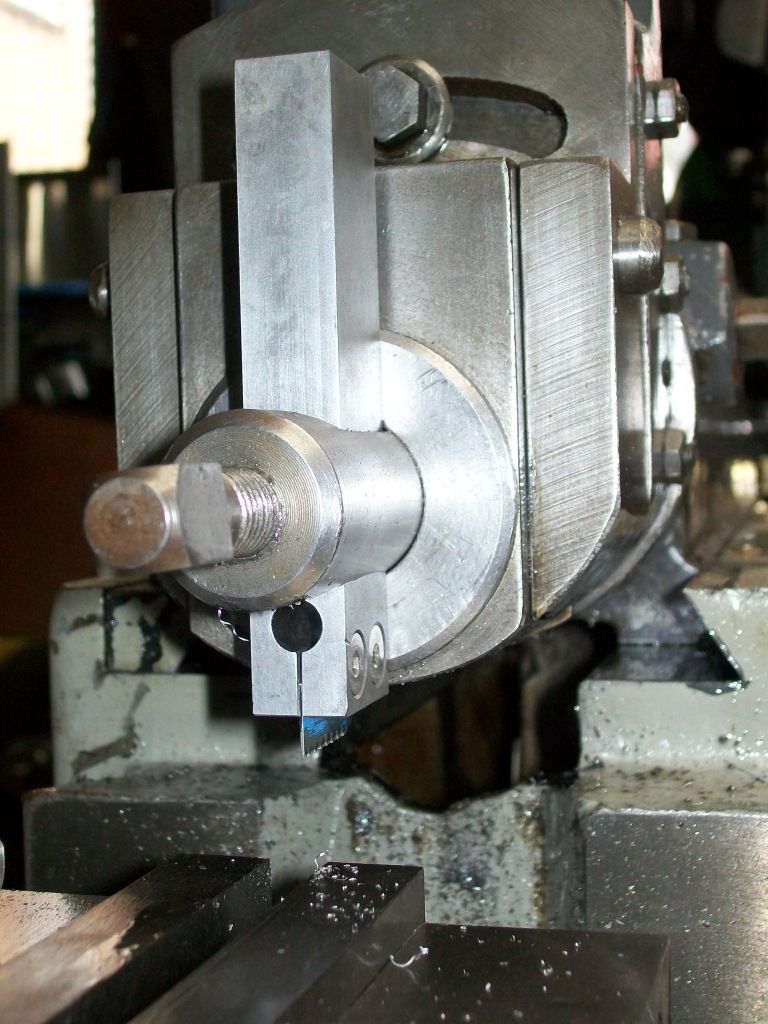

543 forum posts 31 photos | I use any good bits in my Shaper Slitting Saw:

Paul |

| Martin Walsh 1 | 11/11/2013 06:27:59 |

| 113 forum posts 2 photos | I have used worn hacksaw blades as parting tools successfully in the past also used them for packing for the toolpost not needed now as I have QCTP

Best Wishes Martin |

| richardandtracy | 11/11/2013 08:43:03 |

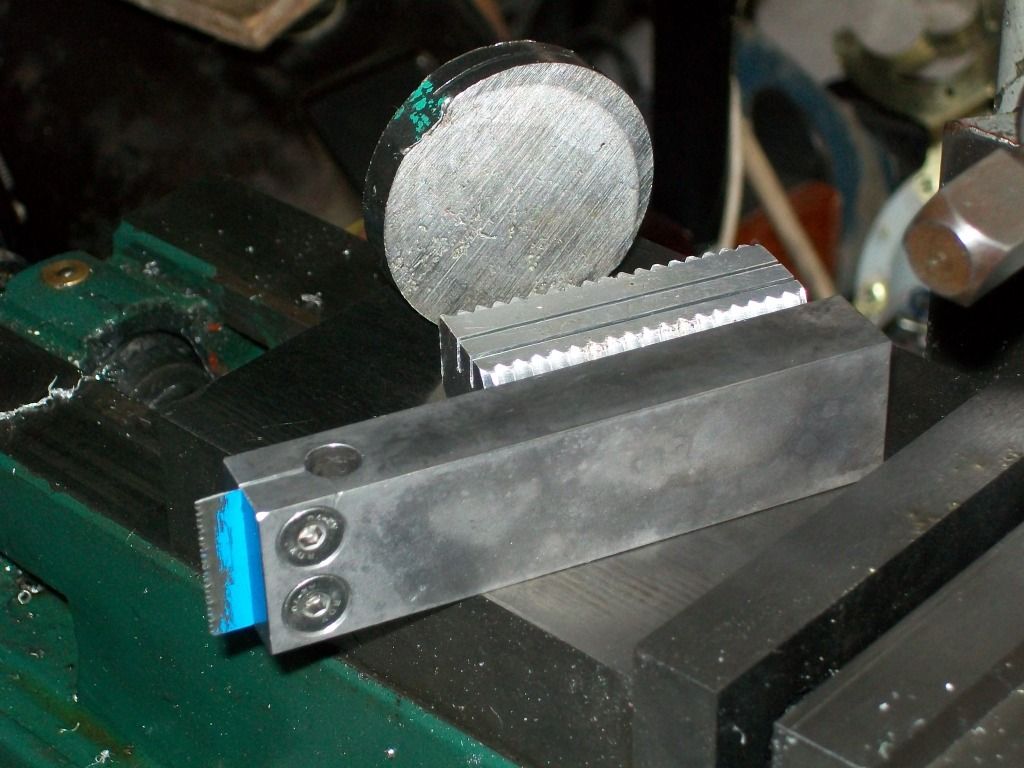

943 forum posts 10 photos | Paul, That's brilliant. I would never have thought of that in a month of Sundays. The last blade I hand ground the teeth off the blade, then ground a fine taper on the blade & am using it as an insulation knife for cutting polystyrene insulation. The slight wave from hand grinding (rather than straight) cuts the insulation much more easily.

Regards, Richard |

| Roderick Jenkins | 11/11/2013 09:26:45 |

2376 forum posts 800 photos |

Some little chisels for carving the rose in a lute soundboard and a thin parting tool holder, I think this was a Len Mason design - also good for piston ring grooves. cheers, Rod |

| Springbok | 11/11/2013 09:34:15 |

879 forum posts 34 photos | I have used these old saw blades for a number if things, |

| Alan Jackson | 11/11/2013 10:15:45 |

276 forum posts 149 photos | I made a hacksaw sharpening jig by clamping the hacksaw blade in a slit cut in a piece of gas pipe which had a lathe centre support on one end. This assembly was mounted in the lathe with the screw pitch set to the teeth pitch. A dremel was mounted on the topslide with a thin grinding disc and the teeth were sharpened by powering the dremel while the sawblade was rotated at the screw pitch. It worked really well, the saw blades were nice and sharp , really good for brass. Alan |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in