whats wrong with my thread/screwcutting

| capnahab | 12/03/2012 19:51:18 |

| 194 forum posts 17 photos | Thought I would try and replicate the thread on my toolpost lever. seems to be 22tpi using my handy gauge. I used the set over method with the top slide set at 27.5 and my tool at 55. This is the result. It looks not bad but will only screw into the corresponding hole by about 3/4 a trun then it binds. The profile is not symmetrical , - I think due to the way it was produced. I used a mandrel handle. Any thoughts /ideas/ tips/ pointers to a bettr technique would be good.

|

| capnahab | 12/03/2012 19:52:18 |

| 194 forum posts 17 photos | ps , measures spot on in diameter. |

| JasonB | 12/03/2012 20:02:23 |

25215 forum posts 3105 photos 1 articles | You have probably not set your top slide to teh correct angle. It should be 27.5deg from a line ar right angles to the lathe axis not 27.5 degrees from the lateh axis. On most toolposts you need to set it to read 62.5 (90-27.5) on the scale. Jason PS its been covered in detail hear before but teh search is pants. |

| ASF | 12/03/2012 20:21:52 |

| 131 forum posts 12 photos | I thought it should be 60 degree for uts or metric 55 degree for whitworth or bsp

I could be wrong of course |

| Ady1 | 12/03/2012 20:23:07 |

6137 forum posts 893 photos | Any thoughts /ideas/ tips/ pointers to a bettr technique would be good

If you're getting weird results when you shouldn't get weird results...then use delrin. With delrin you can cut your thread in 5 mins flat and then test it Alternatively, use aluminium

When you get it right the thread should be a doddle to screw in, no resistance, nice and snug.

Then do a proper steel one. |

| JasonB | 12/03/2012 20:25:13 |

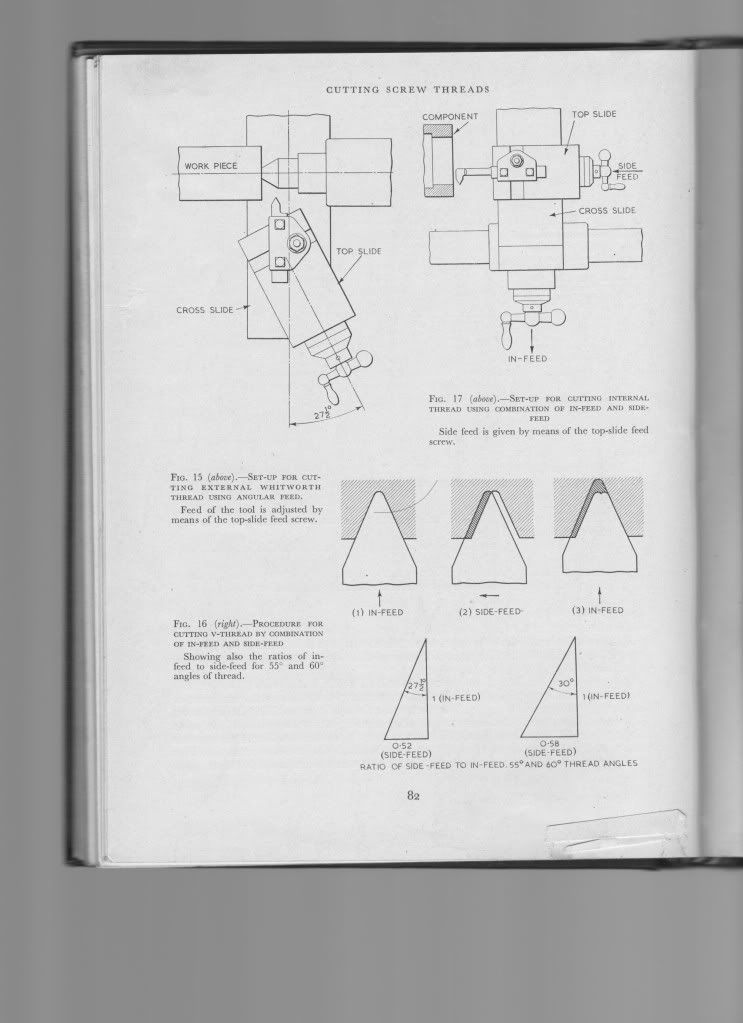

25215 forum posts 3105 photos 1 articles | 55 is the included angle so you set teh topslide to half that so the tool runs down one side of the thread, look at the following pinched from a post on another forum

|

| AJS | 12/03/2012 20:52:04 |

| 37 forum posts | Hi Capnahab It looks like a left hand thread from your photo. Were you cutting from right to left, that is toward the chuck? or from left to right? Alan |

| M0BND | 12/03/2012 20:54:01 |

| 81 forum posts 9 photos | Are you sure that the original thread is 22 tpi? I would start fault finding with that, measure over a few threads and do some calculations. 22 tpi would measure .136" across 3 threads. Also, are you sure it's an imperial thread? This pitch is close to 1mm pitch!? Andy. |

| capnahab | 12/03/2012 21:00:57 |

| 194 forum posts 17 photos | thanks Guys , a pint to Jason so far for the correct diagnosis. what book is that Jason ?. clockie , it is not left hand (maybe my photography). |

| Ian P | 12/03/2012 21:03:00 |

2747 forum posts 123 photos | Only screwing on 3/4 of a turn could be caused by one or more of several factors. First I would establish what thread the original was. If you know the OD and aproximate pitch then by looking in some thread charts you can establish if its metric or imperial, Whitworth, UNF or whatever. If you have cut a close fitting thread but the pitch is only slightly out then it wont screw on very far. Using a micrometer and two wires that is a diameter which sits on the flank of the threads, compare the original with the one you made to see if there is any clearance at all. From a practical point of view, if this part is only for a lever that is going be fixed permanently in place then go with what you have got and get BRUTAL! Use vice grips to install it and you wont need any threadlocking compound.

Ian P Edited to correct poor spelling Edited By Ian Phillips on 12/03/2012 21:04:35 |

| JasonB | 12/03/2012 21:05:55 |

25215 forum posts 3105 photos 1 articles | I don't know what book it is I just picked it up from another forum rather than scanning one of my books and risking copyright issues. As I said its been covered on here in quite good detail with plenty of pics and diagrams but I can't find the post.

Andy, as its 22tpi and being cut at 55deg I would asume the OP has already determined the thread is 5/16 BSF. Ian, The second picture clearly shows that one side of the thread is being cut at 27.5 deg and the other at a much shallower angle, this is the classic sign of the topslide being angled from the wrong axis.

J Edited By JasonB on 12/03/2012 21:09:45 Edited By JasonB on 12/03/2012 21:14:42 |

| Bazyle | 12/03/2012 21:18:14 |

6956 forum posts 229 photos | There are some other catches too. You say spot on diameter and are probably comparing original and copy but often people forget the crests should not be pointed and are flat or rounded depending on thread by about 1/8 depth. So the starting diameter is less than nominal. If not the nut can bind on the crests. Then the depth you cut depends on that starting point and whether your tool is pointed, flat, or rounded. The flat and round depend on pitch so every one is different and you may be using a random ground tool. This affects the infeed. Since the calculations still don't account for the quality of your nut it is easiest to start right, get close, then just try the nut until it fits knowing the binding is not the crests but the roots so you just need to cut a little deeper. |

| Nobby | 12/03/2012 23:15:05 |

587 forum posts 113 photos |

Hi |

| Ian S C | 13/03/2012 09:55:37 |

7468 forum posts 230 photos | I think you would have less trouble if you set up, and go straight in,as Nobby says, rather than setting over, make absolutly sure that the tool is correctly set, take your time, and if you can find a nut that has the same thread, it will make it easy to check your progress. You don't have to be too fancy, my first thread was a 1" whitworth one, and the tool was a bit off an old sqare file, the only problem with whitworth is the round creston the thread, quite noticable with 1", I remember at school we were taught to use a chaser to finish the thread, this is not needed with SAE, or Metric threads. Ian S C |

| Robert Dodds | 13/03/2012 10:51:43 |

| 324 forum posts 63 photos | capnahab, There is little mention at present about checking the effective thread dia. Using three equal small wires you can mic over the original one and then repeat on your new one . It seems from the photos that your new thread is sharper crested than the old one and that might indicate that you need to go deeper or widen the thread. Another quick way to compare the 2 thread forms is to lay the two threads together against a bright sky. This would confirm your TPI and give some indication about the match of you thread profile. As a rule of thumb you don't often find metric threads mixed with imperial dimensions. A check of the surrounding diameters and lengths will often confirm which you are dealing with . Bob D |

| AndyP | 13/03/2012 11:03:30 |

| 189 forum posts 30 photos | The first photo looks like a square thread to me, a white background would help a lot, if you offer your cutting tool up to the original thread does it fit well? Andy |

| Ian S C | 13/03/2012 11:13:01 |

7468 forum posts 230 photos | What make of lathe is the handle off, that would give us some idea of the thread, if it's british, theres a good chance it's a whitworth thread, otherwise, unless it's from the USA, the threads will be metric. Ian S C |

| Russell Eberhardt | 13/03/2012 11:19:28 |

2785 forum posts 87 photos |

Posted by JasonB on 12/03/2012 20:02:23:

You have probably not set your top slide to teh correct angle. It should be 27.5deg from a line ar right angles to the lathe axis not 27.5 degrees from the lateh axis. On most toolposts you need to set it to read 62.5 (90-27.5) on the scale. For W.W. form threads I always set the top slide to 25 deg. as recommended by Geo. Thomas. This makes the trailing edge of the tool take a fine skim and results in a smoother thread. It also makes the calculation of the feed depth easier! Capnahab, if you want a reference book with a good treatment of screwcutting I can recommend Geo. Thomas "The Model Engineers Workshop Manual". Russell. |

| Bazyle | 13/03/2012 13:19:28 |

6956 forum posts 229 photos | A new contributer to MEW issue 188 also appeared on this forum yesterday, Rick Sparber. His website has two tutorials on thead cutting. Several days of reading there actually. Help me to hit my download limit with something useful for a change. http://rick.sparber.org/index.html this is the first one http://rick.sparber.org/ftt.pdf and more http://rick.sparber.org/spt.pdf

|

| capnahab | 13/03/2012 21:28:58 |

| 194 forum posts 17 photos | thanks for all the helpful replies. The toolpost is Aloris . I emailed them , - thread is 3/8 , 24 tpi. So the suggestion it could be a 1mm thread is probably right . Had a go with the thread gauge again. its not that easy to use, seems 1 mm . Will try again. Nice site from rick. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in