Screwcutting Crashes -

| SillyOldDuffer | 10/05/2017 20:43:23 |

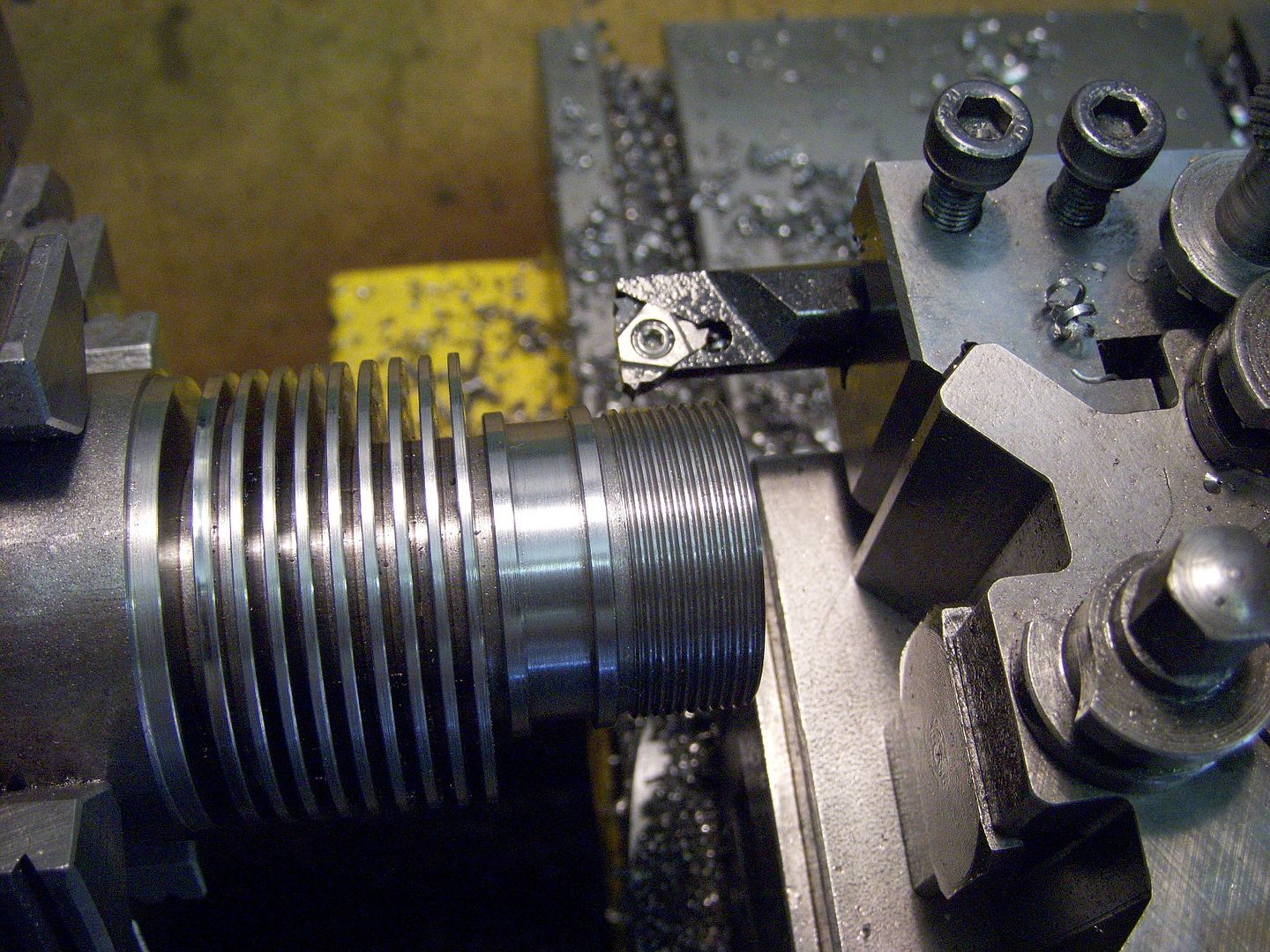

| 10668 forum posts 2415 photos | I'm back at the bottom of the class again. Whilst screw-cutting on my metric WM280 I crashed the saddle into the headstock. (Actually the end of the spring guard over the leadscrew,) Again! I've set the top-slide at 60° (to give a 30° approach with the top-slide) as shown in the picture. With a 4-way toolpost you can see this means that it's very difficult to get the tool close to the chuck without hitting something. What I don't like:

I find threads cut with the top-slide at an angle are much less likely to tear than when I wind the tool in at a right-angle with the cross-slide. But the downside is that I crash if I'm slightly late disengaging the half-nut. This isn't ideal! Am I doing something wrong? Dave PS. Sorry about the sideways photo. I can't work out how to rotate pictures once they're on the forum. |

| Roger Williams 2 | 10/05/2017 21:00:59 |

| 368 forum posts 7 photos | Dave, have a look on utube for Joe Pieczynski, hes done a video about screwcutting the other way round, ie, from headstock outwards . Saves crashing ! I think its called, " Threading, best teqnique ever " Edited By Roger Williams 2 on 10/05/2017 21:04:54 |

| Gray62 | 10/05/2017 21:08:16 |

| 1058 forum posts 16 photos | I've rotated the pic so it's a bit easier to see what is going on. I don't have any suggestions to help other than to say that on my WM250V and on my bigger GH1330 gear head lathe, I removed the leadscrew covers as I found that because of the way they are mounted, they prevent working close to the headstock, particularly when working on thin pieces mounted on the faceplate. ( in fact on both lathes it was impossible to skim the faceplates without having a ridiculous tool overhang.) |

| Russell Eberhardt | 10/05/2017 21:22:46 |

2785 forum posts 87 photos | A quick change toolpost would move the tool further left or you could make an extension piece to fit your existing four way toolpost. Russell. |

| Andrew Johnston | 10/05/2017 21:29:23 |

7061 forum posts 719 photos | I always screwcut with the topslide parallel to the lathe axis and locked, so clearance isn't a problem. I've not generally had a problem with tearing, but find that a spring pass or two can get rid of any roughness. Mind you I tend to use inserts for standard threads. It might be worth looking at an insert and trying to grind a HSS tool copy. Andrew |

| Tony Pratt 1 | 10/05/2017 22:10:22 |

| 2319 forum posts 13 photos | Do a 'dry run' without the spindle moving to check for possible collisions, slow your rpm to allow more time to react. Tony |

| SillyOldDuffer | 10/05/2017 22:13:37 |

| 10668 forum posts 2415 photos | Many thanks for the replies and to Graeme for rotating the photo. (Makes a big difference!) I've just watched a couple of Joe Pieczynski videos - very interesting. He made cutting threads out from the headstock in reverse look dead easy so I shall give that a try tomorrow. I'm almost convinced I need a quick-change tool-post as well, gosh they're handy. Shame about spending money - I have deep pockets and short arms. I shall see if extending the tool-post can be done out of my junk box. Despite being Ta, Dave |

| Clive Foster | 10/05/2017 22:38:32 |

| 3630 forum posts 128 photos | There are a number of less costly ways than a QC tool post of getting round this problem. Here are three examples:- 1) Revise the tool grind so that the tool post can be set square to the top slide. Essentially you move the tool shape round by 30° instead of the tool post. Disadvantage is that the tool post is no longer parallel to the lathe axis so the overhanging corner could come into contact with the job on longer threads. 2) Make an offset carrier for the threading tool. Basically a slotted block with a bar on the back to clamp in the tool post slot. Similar to the common carrier for insert parting tool blades. 3) Make a larger tool post with its base reaching out to the corner. This is the way I'd go having used a bunch of 4 way posts as a poor boys QC substitute in SouthBend driving days. Built up construction from two plates and a centre block glued'n screwed together is quite satisfactory so relatively simple to do using stock materials. Ideally you need something faster than the usual nut holding everything down. Especially if you find, as I did, that a fully loaded four way tends to have unacceptable vampire, or even carnivorous, inclinations so a two slot block is much safer. There are several other perfectly acceptable methods but those are enough for a forum post. I started to do an article for Neil on various less costly and easily made methods of adding most of the virtues of a QC system to a basic top slide. Nearly all the concepts covered would have solved your problem. Unfortunately it got a bit out of hand. Maybe I'll finish it and do as serious edit this winter! Clive |

| JA | 10/05/2017 23:03:08 |

1605 forum posts 83 photos | Dave The only reason for going to the bottom of the class is that you failed to check the clearance between the chuck and everything else through the whole machining operation before starting the lathe. I do not know the lathe you are using but you need more space. As far as I can see from the photograph there are two ways of doing this:

I have frequently cut threads, externally and internally, and always quite a bit of thought is required in setting up the job. As you have done I have always angle the top slide. I feel that the successful cutting of an external thread is the second right of passage with a lathe (the first being setting up a round bar in an independent four jaw chuck). You won't be bottom of the class for long. JA |

| Thor 🇳🇴 | 11/05/2017 05:45:48 |

1766 forum posts 46 photos | Hi Dave, Sorry to hear about your crash. I have a 290 lathe with a 3-phase motor and inverter. I made some special toolholders for my simple QCTPwith a narrow slot so the HSS toolbit just fit. I can also turn down the speed as I am approaching the end of the thread, if I am very close to the chuck I stop the lathe and turn the chuck by hand for the last turn or so, at least for small diameter work. Thor |

| not done it yet | 11/05/2017 06:13:19 |

| 7517 forum posts 20 photos | Yet another couple of possible alternatives.

Use a smaller chuck or thread with a die. |

| Speedy Builder5 | 11/05/2017 06:57:20 |

| 2878 forum posts 248 photos | Suggestions:- |

| JasonB | 11/05/2017 07:43:43 |

25215 forum posts 3105 photos 1 articles | You could get yourself a 5Ccollet chuck then the topslide will pass under it, also puts the work slightly further from the headstock/screw cover. I use the left to right method quite often as when working to a step you can run the lathe as fast as you like without having to wory about disengaging the feed in a split second.

|

| john carruthers | 11/05/2017 07:57:03 |

617 forum posts 180 photos | How about using an L shaped tool, like an internal threading tool?( the cutting tip would be at the top of the L from above). |

| richardandtracy | 11/05/2017 08:35:11 |

943 forum posts 10 photos | Thanks Jason, you have just helped me hugely. My WMT300 has no half nut, so there is no way I can release it coming up to a shoulder. Means I have always done threading by turning the spindle by hand and the cutter moving towards the headstock, which takes ages. Never occurred to me to do it the way that you showed in your photo. May have to return it to position by hand for subsequent cuts, but that's a 50% time saving. Now, if I put a cam lever on the end of the spindle handle I made up to make it 'very quick release', that'll be it sorted both ways. Regards, Richard.

|

| SillyOldDuffer | 11/05/2017 09:57:29 |

| 10668 forum posts 2415 photos | Posted by JA on 10/05/2017 23:03:08:

Dave The only reason for going to the bottom of the class is that you failed to check the clearance between the chuck and everything else through the whole machining operation before starting the lathe. ...You won't be bottom of the class for long. JA Might be worse than that! I did check the clearances before starting. I also managed to cut the first thread without getting it wrong and was in a state of unjustified confidence. The cutting towards the chuck method goes horribly wrong for me because I'm likely to be too slow disengaging the lead-screw when the tool reaches the end slot. When that happens the half-nut is milliseconds away from a jam after which the only way out is to hit the big red button whilst praying that nothing has broken. I can disengage reliably with the lathe screw-cutting at 30rpm but not at 150rpm. The higher speed makes a cleaner cut as well as being faster. (In one of Joe Pieczynski's Youtubes he screw cuts in towards the chuck at 235rpm, his fault is to disengage too early, for which reason he recommends cutting out left to right. ) Anyway, lots more suggestions to think about were posted whilst I was asleep. I'm starting to understand why people invest in 'luxuries' like 5C collets and quick change tool-posts. Many thanks chaps, now I'm more educated I should do better this morning. Ta, Dave

|

| Hopper | 11/05/2017 11:24:45 |

7881 forum posts 397 photos | Posted by SillyOldDuffer on 10/05/2017 20:43:23:...

...I find threads cut with the top-slide at an angle are much less likely to tear than when I wind the tool in at a right-angle with the cross-slide. But the downside is that I crash if I'm slightly late disengaging the half-nut. This isn't ideal! Am I doing something wrong? Dave, there is no need to angle the topslide. You can leave it at a right-angle to the cross slide but still not have to feed the tool straight in. All you do is advance the top slide by half the amount you wind the cross-slide in. EG, if you take a .010" cut by winding the cross slide in by .010", you wind the top-slide toward the chuck by .005". This moves the tool .010" inwards and .005" sideways, resulting in a tool movement equivalent to just under 30 degrees and results in the tool cutting on the one edge only, with a super light clean up cut on the other edge. Using this method also means that once you get to full thread depth with your cut, but the nut still won't screw on, you can take a clean up cut or two by advancing the top slide a thou or two, then pulling it back a thou or two, so the both flanks of the thread are cleaned up without increasing depth. This method is commonly used in industry. No, you dont have to calculate exact ratios to suit BSW profile etc. 1 unit inwards, half a unit sideways will work perfectly for both 60 degree and 55 degree threads. For Acme threads, you advance the top slide one quarter of the amount you wind in the cross slide. |

| duncan webster | 11/05/2017 11:44:10 |

| 5307 forum posts 83 photos | +1 for Hopper's method, just remember that on a metric lathe the crosslide reads diameter (ie twice the slide movement) whereas the top slide reads actual movement. Set top slide to zero, move cross slide till tool just touches job, set to zero, back off saddle clear of job, advance cross slide say 0.4mm, advance topslide 0.1 mm and take first cut, repeat ad nauseam. By initially setting everything to zero, the topslide reading keeps track of where you are, Oh yes I can forget! I grind screwing tools so that the point is to the left of centre, and unless you're mass producing I wouldn't bother with carbide Edited By duncan webster on 11/05/2017 11:44:31 |

| JA | 11/05/2017 11:47:04 |

1605 forum posts 83 photos | Dave Is this a first attempt or is for a specific job? If it is the first, it would be far better to start with a something like a 1/2" mild steel bar. Put it in the chuck, face and centre drill the end. Then turn down the bar to the core thread diameter for a short distance. Next Release the bar and move it about to give about six inches of length, reclamp the chuck. Support the free end with a centre in the tailstock. Using a parting off tool at low speed cut a groove to the same diameter as the thread core close to the chuck. Now everything is of a sensible size and you will have a run-out at either end of the thread for the tool. Quick comment after reading Duncan's reply. If numbers are involved write them down on a piece of paper first. JA Edited By JA on 11/05/2017 11:49:36 |

| Hopper | 11/05/2017 12:46:33 |

7881 forum posts 397 photos | Posted by JA on 11/05/2017 11:47:04:....

..If numbers are involved write them down on a piece of paper first....

Felt pen marks on the graduated handwheels work well too. Be sure to rub them off afterwards so they don't cause confusion on the next job. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in