Countersinking problems

| Philip Rowe | 25/01/2017 16:39:42 |

| 248 forum posts 33 photos | When countersinking small holes around 2 - 5mm diameter I use a rose type Countersink bit only because I have been unable to source any single flute cutters that small. This normally leads to chattering and inevitably a multi facetted countersunk hole. Ok, most of the time it doesn't actually matter as the screw head covers the marks, but I would like to get it right. More years ago than I care to recall I was taught as an apprentice to reduce the depth of cut of the Countersink bit by placing a piece of rag between the bit and the workpiece and this would stop the problem. Sometimes I find that this does work but not always and I have been unable to find a guaranteed process. Maybe someone here might have an idea. I forgot to mention that this is mainly in brass and aluminium but sometimes mild steel and I'm using a hand drill. Phil |

| John Haine | 25/01/2017 17:10:05 |

| 5563 forum posts 322 photos | I find that the main cause of chattering is running too fast, and perhaps too little pressure. I was countersinking holes in ali at the weekend with my Bosch variable speed drill with no problem but occasionally pulled the trigger too hard and got chattering. |

| Michael Gilligan | 25/01/2017 17:13:59 |

23121 forum posts 1360 photos | Phil, I have some small 3-flute 'piloted' countersinks ... similar to those shown here: **LINK** http://www.bsa-regal.co.uk/?category=cuttingtools&page=home Highly recommended. MichaelG. |

| JasonB | 25/01/2017 17:16:21 |

25215 forum posts 3105 photos 1 articles | 90degree spotting drill will also work well as a countersink. |

| Andrew Johnston | 25/01/2017 17:20:38 |

7061 forum posts 719 photos | Bin the rose countersink; they're alright for wood but hopeless on metal. I use 476 series 3-flute machine countersinks by Guhring: They work fine on the vertical mill and in a hand drill, with no chatter. On the vertical mill I normally run around 600rpm. The countersink shown is 10mm, and goes down to 2.5mm. But Guhring do smaller ones, down to a 1.3mm hole. Andrew |

| mechman48 | 25/01/2017 17:24:57 |

2947 forum posts 468 photos | Run at a slower speed... add a bit of emery cloth ((abrasive side down ) between the bit & the material is one of the tricks I was taught during my apprenticeship.

|

| Vic | 25/01/2017 17:52:33 |

| 3453 forum posts 23 photos | I use three flute or snail counter sinks and don't have any problems with chattering. |

| Vic | 25/01/2017 17:54:56 |

| 3453 forum posts 23 photos | Posted by JasonB on 25/01/2017 17:16:21:

90degree spotting drill will also work well as a countersink. Never thought of that but it would be good for small holes. I keep 6 and 8mm spotting drills so I'll have to try and remember this. Thanks Jason. |

| JasonB | 25/01/2017 18:28:09 |

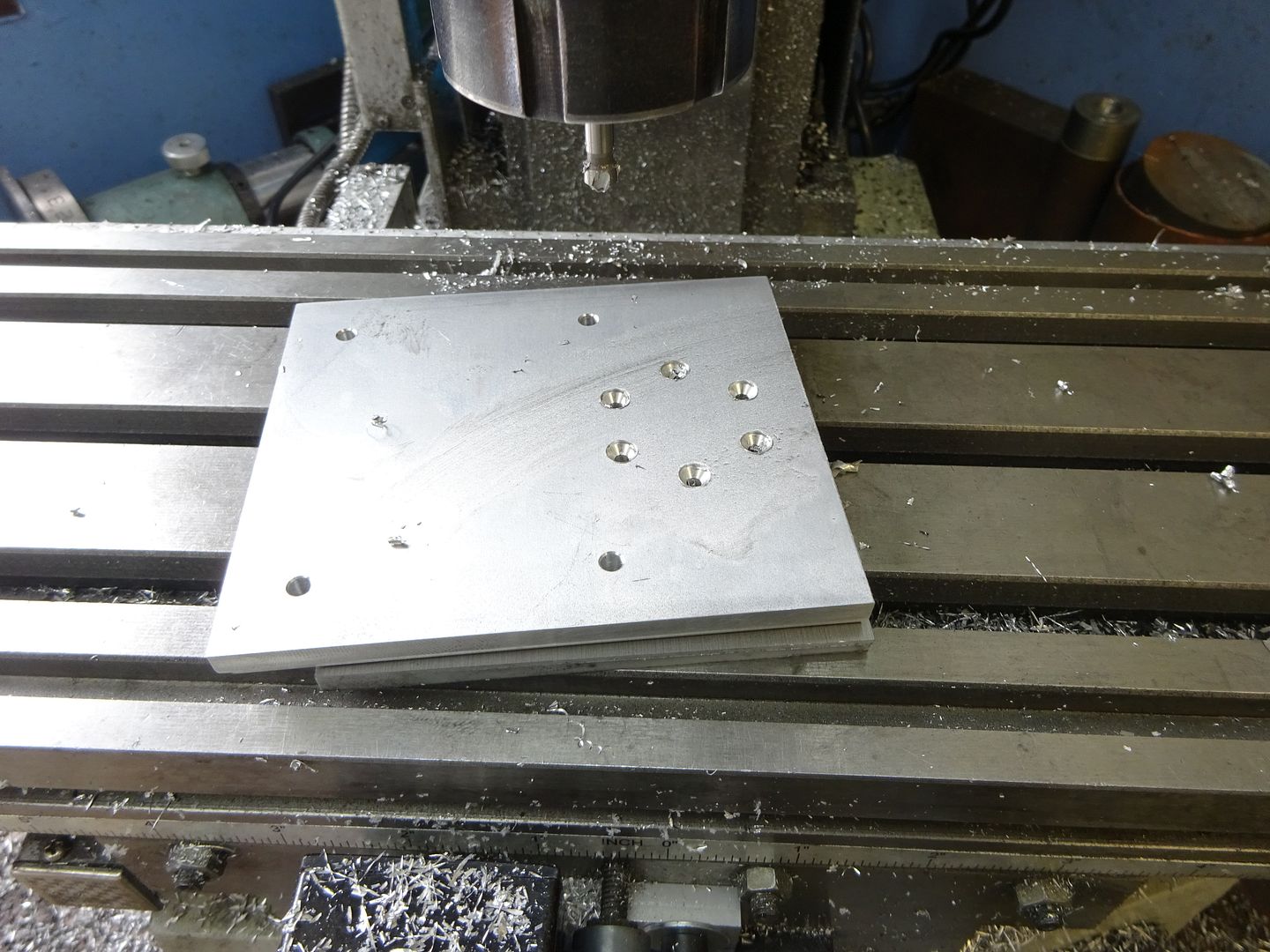

25215 forum posts 3105 photos 1 articles | Vic the idea is to actually spot them deeply to form the CSK as the first op and then drill the hole but can also be used afterwards. Another good make of the 3 flute ones that Andrew showed is Ruko, this is one of their 6mm head ones on a 5mm shank into 6082

|

| Neil Wyatt | 25/01/2017 18:36:16 |

19226 forum posts 749 photos 86 articles | I have a no--name 3-flute one that came in a set of three bits (costing less than a Guhring name label I suspect) and it works very well. There were also very nice single flute countersinks at MEX that work very well. Neil |

| Andrew Johnston | 25/01/2017 19:11:59 |

7061 forum posts 719 photos | Posted by JasonB on 25/01/2017 18:28:09:

Another good make of the 3 flute ones that Andrew showed is Ruko....... Agreed, I've also got a Ruko one of the same size as the Guhring one. Whichever one I find first in the drill drawer is the one that gets used. Both work well. Andrew |

| John Baron | 25/01/2017 20:17:44 |

520 forum posts 194 photos | Try "Weldon" single hole countersinks. I have a set that goes from 1mm to 25 mm. For holes 5 mm you need a 3 to 6 mm one. That is one of the double ended ones.

|

| Philip Rowe | 25/01/2017 20:51:21 |

| 248 forum posts 33 photos | Thank you gentlemen, lots of different ideas and suppliers for me to choose from. I do like the idea of spotting drills as I have been thinking for a while about trying these as an alternative to centre drills. Phil |

| Paul Lousick | 25/01/2017 21:48:51 |

| 2276 forum posts 801 photos | I do not have a set of spotting drills but always use a centre drill to accurately locate the position of holes, then drill thru with a larger drill of the correct size. Why not use a centre drill of suitable size to cut a pilot hole and also a 60 degree countersink to the required depth, then finish the hole with a drill for the finished hole size and clean up with a 90 degree countersink cutter. (have not tried this but will give it a try) Paul. |

| julian atkins | 25/01/2017 23:55:15 |

1285 forum posts 353 photos | Hi Philip, I have always encountered similar problems in the pillar drill. I have various cutters/bits, but few avoid the problems described. I would suggest that if you are handrilling only, these problems will not go away and a pillar drill must be used instead. For excellent results everytime the work is located on wood on the pillar drill table. The speed is knocked down to the lowest (which on my Fobco Star is quite high). The stops are used for depthing, and when near depth the motor is turned off so the final revolutions are made slowly as the depth stop engages. For some reason the wood on the table seems to ovoid the problems you encounter, and leave a clean perfect countersink. Perhaps it dampens out the oscillations. An electric handrill goes far too fast for countersinking. However a hand drill turned by hand will produce very good results. I have HSS wood type countersink bits and HSS specially for metal. I have also made up special countersinks and counterbores in silver steel. Always use a depth stop, and always use a wooden base on the pillar drill table. Others far more experienced than me may be able to give a far better explanation. A hand drill in my book is a drill hand held and hand turned, with which I have had excellent results in countersinking in metal. Cheers, Julian |

| John Reese | 26/01/2017 01:07:35 |

1071 forum posts | I have also had very poor luck with multi-flute countersinks in metal. My preference is the zero flute (with a hole through the body) or a single flute. Both of those are chatter free and both can be resharpened with a Dremel. Just work the inside of the hole on the zero flute or the rake face on the single flute. One exception is a multi-flute carbide countersinl made by M A Ford. I suspect the 6 flutes are unevenly spaced to prevent chatter. If I have many holes to countersink I use a micro adjust countersink. It has a stop collar that can be adjusted to maybe .001". If you can find the tool used, I highly recommend it if you can find one. The cutters I have for mine are piloted. One cutter accepts interchangeable pilots. I believe the tool was originally designed for countersinking rivet holes in aircraft. Those who said to slow down the cutter were absolutely right. In effect it is the same as increasing the feed rate. A timid touch will almost guarantee chatter. |

| Hopper | 26/01/2017 04:27:44 |

7881 forum posts 397 photos | I just use an ordinary drill bit ground to 90 degrees. Drill bit is just a gnat's larger diameter than the the screw head. Then drill the countersink and continue going for another few thou, depending on the size of screw, so the hole is parallel sided for the same depth as the head of the screw is parallel on the very edge. Run it slower than a normal drill bit by a good bit. Works for me. Perfect countersink every time. |

| John Reese | 26/01/2017 04:46:36 |

1071 forum posts | I haven't tried that method. In my experience a 2 flute drill will try to walk around the hole until the flutes are into the work. The result is a 3 lobed hole. I will try grinding a drill to the correct angle and see how it works. I suspect it would be best to grind less relief than on a standard drill. That should help eliminate "walking" For some crazy reason the US standardized on 82 deg. for the countersink while most of the world uses 90 deg. |

| Ian S C | 26/01/2017 09:18:57 |

7468 forum posts 230 photos | I found a new use for broken center drills, I reground the 60* tapered bit to 90*, and this works well. Ian S C |

| Chris Evans 6 | 26/01/2017 09:25:21 |

2156 forum posts | Plus one for the spotting drills, available in 90 and 120 degree versions. I have used them for over 20 years, try them and you will never go back to using a centre drill even on the lathe. The only time I use a centre drill is if I am going to use a centre in the lathe, even then the centre drill is shortened to eliminate breakage. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in