Best way to cut stock to size

Best way to cut stock to size

| Michael Briggs | 20/12/2016 21:58:37 |

| 221 forum posts 12 photos | I have an Evolution Rage 4 cut off saw, I have used it to cut mild steel section for machine stands. Very noisy and hot metal chips everywhere but it did the job well enough. I tried it once with stainless steel, the blade lasted a few seconds. Regards, Michael. |

| Bazyle | 20/12/2016 22:53:49 |

6956 forum posts 229 photos | By the way for those strangely doing this sort of thing inside you are allowed to build a car port structure (in UK) without planning permission up to garage size and can be out the back with no car access. |

| bricky | 21/12/2016 06:55:10 |

| 627 forum posts 72 photos | I have used a jigsaw with a metal cutting blade for cutting 3mm plate lengthways,don't force the cut and patience is required .A word of warning about using angle grinders,not about safety but consequenses that have arisen from my use of the tool.I was asked by the client on site if I knew what was wrong with her window as it had become spotted and grainy.I didn't know.On another site I was cutting mesh close to the house and the sparks hit the window and the steel particles melted and stuck to the glass,which I had to replace at £400. Now I was aware of the dangers and what I had done to the first ladies window Which I peplaced for £80.Moving on to another extension I had to cut another lintel,the consevatory was 7mt long so I thought I would be safe,but The sparks had reached the far end helped by the wind and wrecked £650 worht of glass.Whilst cutting outside remember my experiences and make sur you have the sparks well away from any glass. Frank |

| Roger Williams 2 | 21/12/2016 08:32:12 |

| 368 forum posts 7 photos | Bricky, I did exactly the same to our patio window, I thought I was far enough away too !!.😥 |

| Ian S C | 21/12/2016 08:56:50 |

7468 forum posts 230 photos | I have a friend who managed to embed the window in his workshop with steel and grit from using an angle grinder. but worse than that a chap I was working with set fire to the crutch of his overalls while using an angle grinder, luckily no damage to the important parts, it was his wedding the next day. Use the angle grinder, and for the long cuts clamp a bit of steel along the line, and use this as a guide. Ian S C |

| BW | 21/12/2016 09:39:16 |

| 249 forum posts 40 photos | Posted by Muzzer on 20/12/2016 20:51:53:

Like Brian_G, I've heard good things about the Evolution Rage thingies. They are only(?) £100 and seem to be pretty effective. I'd consider one of them if I didn't have a band saw, particularly if I also played with The Brown Stuff. Murray I've been aware of these saws but never seen one What thickness of solid round or square bar has it been known to cut ?

Bill |

| Roger Williams 2 | 21/12/2016 10:06:51 |

| 368 forum posts 7 photos | Bill, ive the one with the 350 mm disc and have cut many 2 inch mild steel bars on it. Take it easy, and they will cut just about anything. Very noisy though. With some juggling, I cut through a 6 inch square RSJ the other day. |

| Ajohnw | 21/12/2016 10:17:34 |

| 3631 forum posts 160 photos | A horizontal band saw is probably the most flexible option. It doesn't care what the size of the metal is providing it fits within it's capacity. Having said that though I have turned bar and things like that over to exceed the usual 4" depth. Many of them can also be used vertically by adding a small metal table. Buy one of these and you will put a lot of your cutting needs to bed in one go. There is a thread some where on here where some on complained about how poor the cheap chinese ones are. Replies metioned what usually needs to be done - blade tracking adjustment and the fact that the blade needs to be rather tight. They use a spring to provide the downward cutting force. That may need adjusting on larger bars at the beginning and the latter parts of the cut. It may not cut dead square but will get close enough for quick use of a file on things like angle iron. Frankly I wouldn't be without mine and many owners feel the same. Chop saws are sometimes used now. Noisy and I have no experience of them. I'd be surprised if a cheap one is as capable as the above. Bandsaws that can stand up to metal cutting long term tend to be rather expensive. Lots of cheap ones use cheap flimsy die cast supports for the blade guides etc. I bought a dewalt eventually. That was just cutting timber. The metal cutting thickness is severely limited. Personally I would avoid very cheap angle grinders. Following the death of my mother I needed to chop up a stair lift into 3 sections to get it into a van. I bought a cheapy as I didn't have mine with me. I suppose it was running and cutting for maybe 15mins. On the last cut it burnt out, fortunately when it was more or less through. Another tool I wouldn't be without. Buy a decent one if you go this way. The can also be fitted with grinding wheels that are used face on - not on the edge. Also scratch brushes. The other option is a reciprocating saw. At our level that is often a home made one. The best design I have seen is by Myfordboy on youtube. As I see it the options that don't make much noise and are very safe and easy to use are the horizontal bandsaw or the reciprocating one. I don't like noise either. Sparks - well make sure they are flying away from you and use the guard. John - Edited By Ajohnw on 21/12/2016 10:18:03 |

| Vic | 21/12/2016 10:31:25 |

| 3453 forum posts 23 photos | I have a dual speed wood cutting bandsaw. I'm given to believe that if I put it in low speed it will cut aluminium alloy with a HSS blade. Anyone tried this? I'm wondering how long the blade will last! |

| Mike | 21/12/2016 11:26:15 |

713 forum posts 6 photos | Just a question - is it possible to cut aluminium with an angle grinder, or does it clog the disc? |

| Trevorh | 21/12/2016 11:51:45 |

316 forum posts 89 photos | You can get aluminium cutting discs for the 4" angle grinder- screwfix and other places the 1mm ones are good for neat cutting but can and do flex

cheers trevor |

| JasonB | 21/12/2016 12:31:51 |

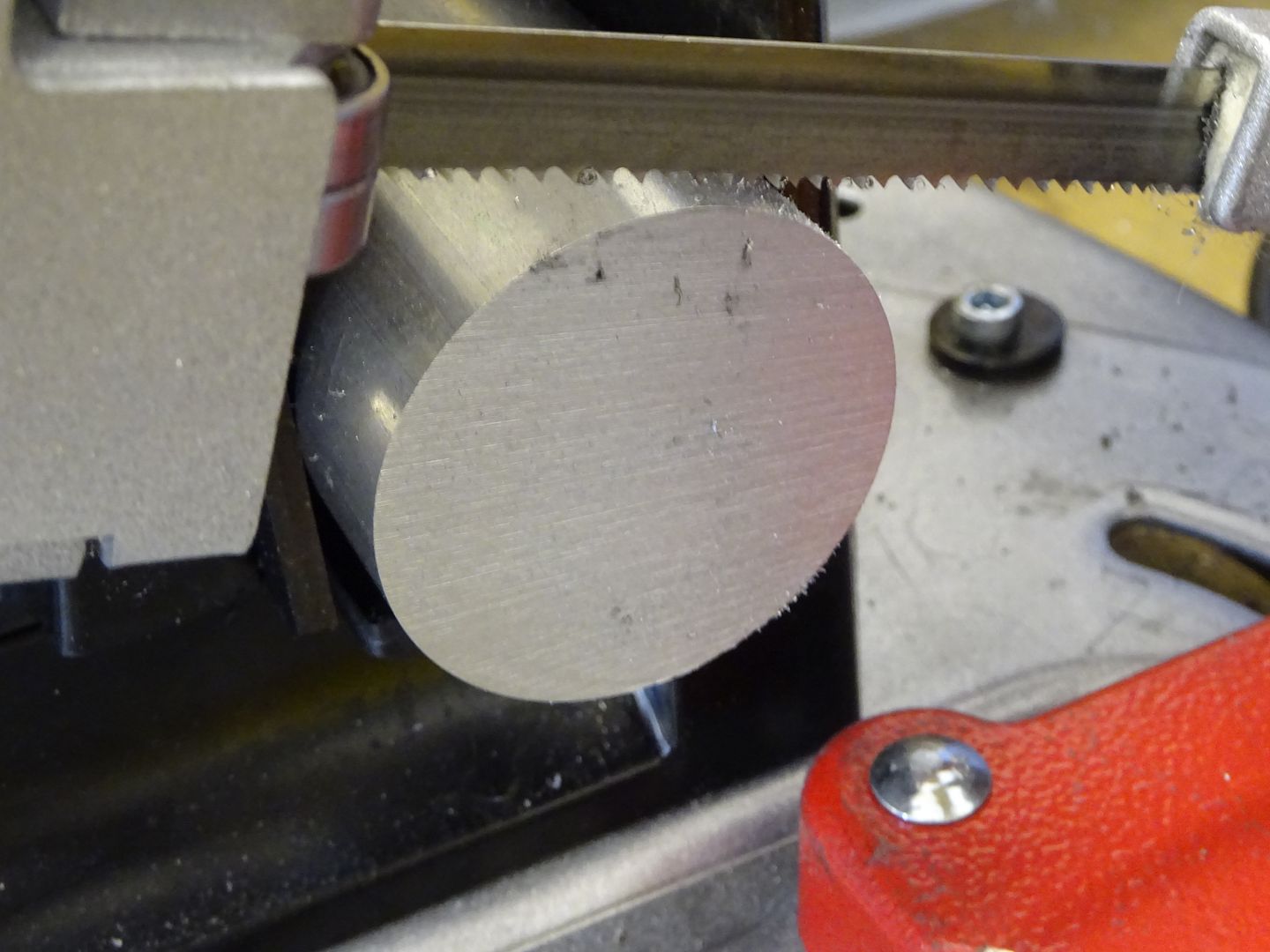

25215 forum posts 3105 photos 1 articles | Vic I have used my old Rexon woodcutting bandsaw on aluminium, this is a bit of 3" square cut with it. Also does brass & bronze

Though now I have got a Femi 782XL which is easier and will also work vertically with the additional table that is avalable. Cut this 2" EN8 in just over 2mins

And some 2x5 CI was no problem

|

| Nicholas Farr | 21/12/2016 12:57:57 |

3988 forum posts 1799 photos | Posted by Mike on 21/12/2016 11:26:15:

Just a question - is it possible to cut aluminium with an angle grinder, or does it clog the disc? Hi Mike, you can cut aluminium with an angle grinder, but most everyday discs do tend to clog up a bit and the cut is not very smooth. To get a good cut, you need a disc for cutting or grinding that is designed for aluminium, especially if you intend to weld the edge that you are cutting/grinding, but they are a little dearer and not every retailer sells them. There are some at this **LINK** Regards Nick. |

| Mike | 21/12/2016 14:33:49 |

713 forum posts 6 photos | Thanks, guys. It's just that I have some 2 1/2-inch aluminium bar to cut into several pieces, and it's proving to be too tiring to hacksaw. A bandsaw would be ideal, but I don't have one - but I do have an angle grinder. |

| Men Ifr | 01/01/2017 22:50:04 |

| 119 forum posts 10 photos | Does anyone have a link to the cheap chinese bandsaws as a good one is well out of my price range. What sort of price am I looking at? |

| norman valentine | 01/01/2017 23:59:50 |

| 280 forum posts 40 photos | Not cutting but grinding. For aluminium, the discs designed for stone work without clogging. |

| norman valentine | 02/01/2017 00:31:59 |

| 280 forum posts 40 photos | Despite all the arguments against angle grinders they are very convenient and cheap. I have used the cheapest from B&Q and yes, they are not great quality but at £20 they are great value. I bought one and used it for six months and it burnt out. I had kept the receipt so I took it back and was given a replacement. That too burnt out after a few more months. I took that back and as there were none in stock I was given a refund. So what is there to complain about? One years free use of an angle grinder. That seems good value to me.

|

| JasonB | 02/01/2017 07:28:20 |

25215 forum posts 3105 photos 1 articles | Posted by Men Ifr on 01/01/2017 22:50:04:

Does anyone have a link to the cheap chinese bandsaws as a good one is well out of my price range. What sort of price am I looking at? Chester and Warco both do cheap ones, not used one myself so will leave that to others |

| Anthony Knights | 02/01/2017 09:17:14 |

| 681 forum posts 260 photos | I am currently on my third cheepo 115mm angle grinder in 15 years. I have still spent considerably less than I would have, had I bought what the purists would call a "proper" machine. Considering the amount of use it gets and the fact that I am in my 70's it would not make sense to splash out on a top of the range piece of kit. It would be different if I used it all the time. I tried a "rage"saw blade but I found it noisier than the angle grinder. Edited By Anthony Knights on 02/01/2017 09:20:15 |

| Nigel McBurney 1 | 02/01/2017 09:50:16 |

1101 forum posts 3 photos | I always use angle grinders outside of my workshop,as the sparks and grit will cause lots of damage,my concrete apron outside the shed is a bit rust coloured,also keep any pets well out of the way as the flying grit can get in their eyes. Unless you are very strong and fit don't be temped to buy a big 9 inch grinder,they can be very dangerous particularly if cutting vertically ,had a couple of near misses one took a lump out of my trousers so its now at the back of the cupboard, they are safer when used horizontally at chest level with a grinding disc,its the cutting discs that can jam and jump out of the work. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

They will also cut timber ideally with a coarser blade.

They will also cut timber ideally with a coarser blade.

Register

Register Log-in

Log-in