Member postings for Men Ifr

Here is a list of all the postings Men Ifr has made in our forums. Click on a thread name to jump to the thread.

| Thread: Record number '0' Vice - 2 1/2" vice - Fibregrip Jaw covers. |

| 14/05/2023 23:18:08 |

Hi all, bit of an old thread but I was also dissappointed with the draper / magnetic style and started making custom fit vice jaws I intend to make sets for all record vices once I get all the dimensions (jaw height is what I need). I can make a set up if you are interested and am looking for people who could measure the jaw height and provide photos once fitted. |

| Thread: Spotted in Pewsey |

| 30/06/2019 11:15:28 |

| 30/06/2019 11:14:58 |

| 30/06/2019 11:14:29 |

I would like to know what this is (above) |

| 30/06/2019 11:13:54 |

| 30/06/2019 11:11:48 |

Spotted some interesting tooling in a watchmakers shop in Pewsey while out for a walk

|

| Thread: Drill sharpener |

| 28/12/2018 14:19:14 |

For any-one else reading this here's another vote for this type using a bench grinder

I set it up to the side of a 80grit (fine) wheel. If you don't already have a bench grinder you could buy a bench grinder plus this type of sharpener for the price of the dedicated sharpeners and I get perfect results every time though smaller than 3mm gets a bit difficult. For small bits <3mm I buy branded Sherwood or similar split point stub drills as for starting holes and the difficult job of driling small holes they are far superior to cheap bits and only requiring the small sizes quite cheap. There is no skill involved really, what is also useful is to cut a set of old drill bits with an angle grinder very short then re-sharpen as stub bits.

|

| Thread: Warco v Chester. |

| 20/12/2018 19:12:55 |

| Having just bought a lathe from Chester (multiple problems with lathe but good aftersalles service) and a mill from SPG tools I would say look at SPG the owner Simon can be a bit difficult to deal with but I am very impressed with the mill, his machines are cheaper than anyone else in the UK and they are degreased cleaned oiled and checked by SPG, I don't think anyone else does this in the UK now. My old small mill was also given a new circuit board after mine failed after a year or so. The Chester machines are just shipped in the crate it came from in China and I found the quality very poor. Ymmv |

| Thread: Myford ML7, or Colchester Bantam/Boxford model A easiest to use? |

| 20/12/2018 19:06:21 |

| Sorry I meant main feed, still getting used to terminology. Yes I've been looking at the feeds and have changed gearing so that position 9 now gives 0.02mm/rev and 1 will be about double that 0.04. I'll see how I get on with that. |

| 20/12/2018 12:52:57 |

Just to update people how I'm getting on with this: As per my other thread the 1st lathe that arrived has pitting in the ways. Chester replaced that with a 2nd lathe and the ways all look good. Unforutunately this 2nd lathe is imperial - I use metric . Due to the difficulty of moving the lathe - it took 3 hours of faffing around with a engine hoist I agreed with Chester it is easier for them to send some metric leadscrews and dials and I will retro fit them to the machine. The 1st lathe had problems the lever would not release the half nuts and this lathe has problems the 1/2 nuts were catching on the leadscrew, this seems to be traced back to a screw missing which holds the lever on, the lever moved out a bit, the ballbearing for the indent has fell out so the lever would wander down when turning. I've resolved that now but needed to strip the apron down. At a quick glance the 3 jaw chuck appears quite inaccurate but I will measure the run out a bit later. I measured the alignment of the headstock to the bed by turning a piece of bar and its was out around 0.16mm over 4". The headstock can be repositioned as it is just bolted to the bed so I am in the process of doing that. It will be intesteting to see how close I can get it I'm hoping for 0.01mm over the 4 inches so we'll see. - If anyone has measured/adjusted theirs what did you get? I'm also thinking I should check the up/down alignment of the headstock, I could do this by bolting a vice to the cross slide and machining the bar from the underneath then measuring taper as normal. I feel like I should at least check this as taking anything for granted with these Chinese machines I think is a mistake. So far I've machined the backplate for the 4 jaw chuck, unfortunately have mads the collar ~0.2mm too small, I went back and checked my measurements what had happened was I measured the internal bore of the chuck with a digital caliper but having pushed the internal jaws in they met the (not visible to naked eye) taper at the end so gave a smaller reading than true. I've obviously also been machining the bar for the taper measurements on the headstock and this works nice, the machine can be run at high speed without loosing power though could do with a finer cross feed so will look what I can do with the gears (gearbox is already at position 1) As a general comment I have also bought a large/240kg milling machine from SPG tools and I appreciate it is bigger and twice the price of the lathe but the appearance, operation, build quality and attention to detail on the milling machine is far far superior to the lathe. Anyway I'm happy to be turning metal but do wonder if i would have been batter off with a Myford.

|

| Thread: Lathe spindle speed and finishing speed/feed |

| 20/12/2018 12:19:34 |

That's useful though may be good to know if that's for HSS or carbide tools and there are no feeds.

I found this very useful diagram from cnccookboook

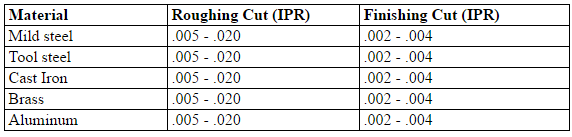

So the surface finish would seem to be limited by a feed so slow that the tool rubs not cuts and spindle speed limited by tool temp What's interesting is I've turned parts with much higher spindle speed than the the table from the 1st link with no problems - if that is a table for HSS tools should it be multiplied by 4 for carbide (even cheap carbide) tools? Is there a limit surface speed for aluminium because it melts? I've took feed rates below

Which gives 0.5 to 0.05mm/rev in metric

|

| 19/12/2018 09:31:55 |

| I've been looking for but struggling to find a quick rule of thumb for lathe spindle speed. Something like work diameter divide by 1000? Also how do I change parameters for finishing cuts? Higher spindle speed plus less feed rate? What is the practical limit for this? |

| Thread: If you bought this lathe what would you do? |

| 12/12/2018 12:58:49 |

| Jason B, yes it's difficult decision what to buy, a lot of the problem is no-one has stock of the bigger lathes. I have tried to buy a 10x22 lathe off quite a lot of suppliers but all were sold. The 920 is only slightly smaller has a gearbox but no variable spindle speed. I did not expect any difference in quality from older vs newer design Chinese machines. But several sellers tell me there is a difference in quality getting better on bigger machines, also this size suits my needs quite well. |

| 12/12/2018 12:53:28 |

| Chester have been quick to respond and we have agreed they will send another machine out Friday and collect mine at the same time. I'm happy with that and will wait and see what the next machine is like. Thanks to all for the replies Edited By Men Ifr on 12/12/2018 12:59:32 |

| 12/12/2018 00:15:17 |

Well thanks for the replies, I'll see what Chester say tomorrow. I'll have a look at the arc website to see what they have got. |

| 11/12/2018 22:00:08 |

So after turning down a nice Colchester as it was too big for me I bought a Chester 920 lathe however I'm not too happy with it at the moment - Do I persist trying to sort it or send it back?

Probably the biggest thing I can't fix really are the bed was not cast properly - the rough area is upto 0.2mm deep. Will it make much/any difference though.. I don't know. I've ran the slide up and down with dial against a reference block and that seems good however that's with no load . There is not much contact between the slide and bed even where the bed is not pitted but I think that is normal for a Chinese machine and can be improved via scraping/lapping.

Another view of the ways

Plenty of grit in the gearbox - but it does have a 9sp gearbox which I like!

More grit/casting sand Other issues - The half nuts are stuck open Grit in most ways and between top/cross slide leadscrew is slightly bent maybe 2-3mm in the middle Some surface rust, I don't think critical but needs cleaning/oiling Safety switch for the chuck cover does not allow cover to be opened. So it's not great - I know it would not be.. but was not expecting it to be this bad. I'll email Chester and see what the say, maybe I'm unlucky and they can swap for a good one.. who knows!

|

| Thread: Removing Grit after Lapping Ways |

| 11/12/2018 12:34:57 |

Is any special method(s) required to remove grit after lapping? After lapping the column on my small mill it was cleaned by rubbing with paper tissues until they came out clean then applying isopropyl alcohol and re-rubbing. I now *think* the oil on the Z column is blacker than it should be which I wonder if that is an indication of either cast iron grit or lapping grit still present? I wonder if post lapping rubbing over dry with a very fine wire brush maybe brass or something maybe better at dislodging any remaining small particles or is there a standard way to do this?

|

| Thread: Myford ML7, or Colchester Bantam/Boxford model A easiest to use? |

| 07/12/2018 20:28:58 |

Oh dear. I went to look at the Colchester the seller was a very nice chap but I think reality set in that it's too big for what I need right now and I didn't want the hassle of installing it in my garage for it to (potentially) sit there for a long time with little use, or regular use for little parts. He had a huge amount of interest in it so was happy to sell it to some-one else and I've bought this from Chester hobby store:

https://shop.chesterhobbystore.com/collections/lathes/products/920-lathe It seemed like a good price for a new 9 x20 lathe and has a 9sp gearbox which I like a lot. I need to add a tacho (already bought for £10) and work out a variable speed without loosing torque. When I rang I was told it also comes with 4 jaw chuck and steadies definitely a bonus as my first job will require a fixed steady. It arrives Tuesday, so looking forward to using it next week!

|

| 05/12/2018 12:43:39 |

I'm not sure how well this link will work but I've bough the Colchester Student advertised at £835, price seemed good, he bought it from a college so no industrial use, he's very local and works at my company so I can trust him. https://www.facebook.com/search/marketplace/?q=colchester%20student&epa=SERP_TAB

I've said I will buy it (with out looking at it) and will goto look at it tonight to work out how to move it. I'm sure if it's in awful condition I could back-out but as he's a professional engineer I'm confident it will be in good nick. It also comes with a home made rotary inverter which needs a bit of repair but if I can get an electronic inverter for not too much cash I think I'll use that but I need to find out if I will loose power/speed that way. Also I don't know if the original motor is 1.5 or 3hp.. Now I need to work out how to move it, he had offered the use of a heavy duty trailer.. but I'm reading some horror stories of people moving lathes now... No accessories other than 3 jaw but will have to work that out later.

|

| 04/12/2018 15:03:48 |

| I was wondering should I get the ML7 as a stop gap and I cannot afford to wait months for a suitable and local boxford or Colchester to turn up, it looks to me via completed listings on eBay that 600 to 700 would be a reasonable price? At least that would get me up and running. Where else should I be looking for bargains? I check eBay Facebook market place and gumtree |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in