Knurling Tools

How to ensure a good quality knurl

| Ajohnw | 11/07/2016 10:00:28 |

| 3631 forum posts 160 photos | Posted by Martin King 2 on 11/07/2016 07:23:35:

Hi All, I would like to buy a set of small PARALLEL knurls for some brass trammel knobs that I need to copy and cannot seem to find any? Any ideas please? Regards, Martin I just looked for some likely candidates on ebay. There are always some listed. I looked for hss, a decent finish and reasonable width as I feel that narrow ones would be far more likely to generate a twisted pattern. Also a chamfer on the edges as that is how knurls always used to be - or at least the ones I have used at work. The ones I bought are pretty coarse and when I knurl things I don't really want a very sharp pattern as they can be uncomfortable to hold. The wheels are 3/4 dia by 3/8. There is some info on knurls in this I'd assume that they also stock some wheels. Using them at a slight angle is worth remembering for coarse patterns but maybe not straight ones. Personally I am not so sure about coated cutting tools. I think that at times it's used to make shoddy products better. Also the lifetime of coated carbide tips. John - |

| Ed Duffner | 11/07/2016 10:08:36 |

| 863 forum posts 104 photos | After buying a few sets of knurls from Ebay I made my own, mainly because I needed a specific geometry but also for the reasons of quality I mentioned on page 1 of this thread. Some professional knurls I'd like to try in the future have a radiused face, apparently to reduce the sideways forces when traversing. I don't know if these could be made in the home workshop without a CNC machine. Ed. |

| Ian S C | 11/07/2016 13:55:56 |

7468 forum posts 230 photos | For nice fine straight knurling, this one is a good one, it takes only a few minutes to make. Got the idea from Stan Bray's book "Introducing the Lathe", you need a bit of scrap steel about 10 mm sq x 75 mm long a small hard pin (old needle roller), a little piece of bronze for a bush, and a flint wheel from a ciggy lighter (I used a BIC disposable). Sorry the photo is not great. Ian S C |

| John Stevenson | 11/07/2016 22:52:08 |

5068 forum posts 3 photos | Posted by Ajohnw on 10/07/2016 18:13:32: This is likely to happen because a given pitch of knurling wheel will only produce the correct finish on certain diameters of work that will go in steps so that they divide exactly into the circumference of the work. John- This is one of those urban legends that get repeated over and over again. Knurling is a displacement operation and as such is very flexible as regards diameters.

Lets look at the logic behind the operation.

One part of knurling is written in stone and that is the wheel. It's steel, it's hardened and it has a given pitch so everything is based round that. So take a 1" wheel with 40 teeth as an example so the pitch is Pi divided by 40. So 3.1416 /40 =0.0785" and will roughly have a depth of half that so say 39 thou. So a bar 2" in diameter should finish up with 80 teeth according the the legend but thats the OD. When it's finished to tips of the knurl wheel will be at root diameter which will be 2" - twice the depth so 0.0785 which gives us a root diameter of 1.9215 which if you multiply by Pi and divide the 0.0785 into it gives you 76.899 teeth. That's a difference of 3 teeth and we are supposed to be working accurately ??

So do you calculate on OD, root diameter or PCD because after all it's a crude gear.

This is very easily proven.

Take a bar and take a clean up skim off it then proceed to machine a series of random steps on it. In this case they vary from base diameter to - 25 thou smaller.

Then knurl it.

You can still see the felt tip marks on it but all these diameters are good, no double knurls because the metal deforms to suit. |

| bodge | 11/07/2016 23:26:10 |

| 186 forum posts 3 photos | Nicely put John S,... diameter dosnt make any difference, nice pics to prove the point...........b |

| Neil Wyatt | 11/07/2016 23:48:13 |

19226 forum posts 749 photos 86 articles | The trouble is the people who wrote long articles for ME explaining how they calculated the right diameter for their knurls, can't be proved wrong because they get a perfect knurl every time... I think it's like parting, once you have a rear toolpost/knurl diameter calculation etc. you approach the job with new confidence instead of pussyfooting about and lo and behold! It works... Neil |

| Clive Foster | 12/07/2016 00:43:22 |

| 3630 forum posts 128 photos | Posted by Neil Wyatt on 11/07/2016 23:48:13:

The trouble is the people who wrote long articles for ME explaining how they calculated the right diameter for their knurls, can't be proved wrong because they get a perfect knurl every time... Neil Nah, no way. If they could get decent knurls every time they wouldn't need the maths! What gets me is that such folk don't actually do the sums properly anyway. If they did it would be immediately obvious that the change in diameter needed to cover one knurl tooth error is very small. Probably around 10 thou for the sizes we deal with. which, as John has shown, is 3/8 ths of nowt when dealing with a metal dispalcement process. That said I have encountered the wrong diameter effect when putting a coarse knurl on a slender brass rod maybe 1/4 inch diameter but probably less. 30 years on I've no clue why the job was done but can still vividly recall the thin sharp swarf that the knurls dug out during the process of equalising diameter to knurl pitch. About 10 times better at getting under the skin and 30 times more irritating than normal sharp brass swarf. Up until then I thought glass fibre was the worst. Not pussyfooting about says it all. Not just firmness tho'. I find that knurl engagement needs to be reasonably fast if things are to work out well. Seems logical that a fast engagement between knurl and work gives the knurl no time to skid or slip as it bites in so the familiar bad job double pattern can't get started. As anyone who has ever used a nutcracker style hand held tool once a double pattern does start its a near impossible job to get rid of it before the work is ruined. Nutcracker types are intersting to use because you can feel what's going on. Good knurling feels distinctly different to bad. I suspect the mechnical disadvantage on Neils tool may actually be a real life advantage because pressure is applied faster for any given rate of screw adjustment. My favourite off set pivot Pratt & Whitney push in tool is probably more reliable than the more usual symmetrical form having the pivot on or near centreline becuase the knurls engage sequentially. One knurl is on centre line and must engage first so all the force goes into starting the first side of the pattern. The second knurl is pulled in just a touch later as the knurl carrier rotates on the below centre pivot. Second knurl probably has an easier time getting started as its working across the very beginings of the other side of the pattern. In practice its the second knurl which can cause problems if you aren't aggressive enough. As I reminded myself this morning by being a bit too gentle on a relatively weak alloy job. The usual symmetrical, pivot on centreline, types need to start both knurls together on virgin metal so force needed for reliability seems to be much greater. Clive. |

| bodge | 12/07/2016 00:59:06 |

| 186 forum posts 3 photos | Neil , you could well be right , Ive never had any trouble knurling , when the knurl is done, it should look well defined and crisp is how i was taught ( B A C circa 1969 ) and nobody said any thing about diameter ( if diameter matters that much why dont knurls come in sets ? other than fine medium and course ) i do remember we used clamp type knurls, so when a marlco knurl showed up at right money i bought it , and it is very nice and easy to use . As for parting off i dont have a problem with that either and dont have a rear tool post, it was a bit dodgy to start with cos i bought a old worn lathe, the saddle and bed have been sorted, and tight new chuck makes it a simple strait forward op On another note im not very good with computers and was seeing what different buttons do ,one button was used by mistake ,the ignore member button i was trying to learn how to do cut and paste and hit the ignore member tab when i should have hit the quote tab , could you undo that for me please.................b

Edited By bodge on 12/07/2016 01:09:50 |

| Marcus Bowman | 12/07/2016 07:57:25 |

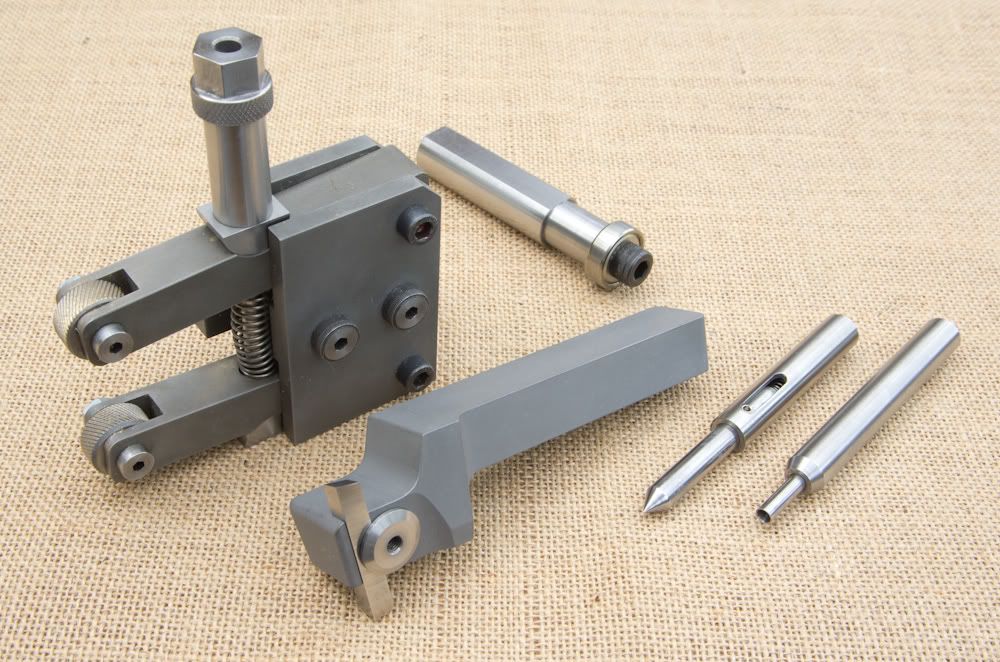

| 196 forum posts 2 photos | I agree that knurling is a displacement operation and that flow plays an essential part. So we can't really say we are "cutting" a knurl. Calculations would be based around pitch and pitch circle diameter, and have their place, but only when calculating using PCD, as when calculating gear dimensions. It think speed of engagement and squeezing/crushing the depth is also essential, as is copious coolant and continuous cleaning/removal of slivers or swarf. That being said, I am far from convinced that most combinations of knurls and workpiece diameters give really cleanly defined knurls on the work. I much prefer to CUT knurls. For me, the most convenient way depends on where the work is, and what the previous operation was. Sometimes that's in the lathe, but mostly it is on the CNC mill, where all manner of patterns are easily achievable. I have sets of good quality knurls in two-wheel squeeze-type holders (as in the illustration in a previous post), and they generally work well. Narrow knurls do tend to have the disadvantage that a greater amount of sideways traverse is required for a given breadth of knurling, so it is more likely that the knurl will tend to wander a little, producing a slightly drunken finish. Any slight out-of-square alignment of the arms or the tool tends to make that worse.

Marcus

|

| Neil Wyatt | 12/07/2016 11:38:29 |

19226 forum posts 749 photos 86 articles | Posted by bodge on 12/07/2016 00:59:06:

On another note im not very good with computers and was seeing what different buttons do ,one button was used by mistake ,the ignore member button i was trying to learn how to do cut and paste and hit the ignore member tab when i should have hit the quote tab , could you undo that for me please.................b I can't but you can, at the top click 'my posts', choose ignored members and you will get a list you can edit (I assume). Neil |

| Ajohnw | 12/07/2016 12:31:34 |

| 3631 forum posts 160 photos | It's not an urban myth at all because the step in depth a given pitch of knurl wheel needs to work more or less remains the same irrespective of the works diameter. The straight knurl I was using is pretty coarse for use on sub 6mms dia and I am 100% sure I would have wrecked it if I had tried to go deeper into the "next step". Knurls do have steps in depth where the pattern fits correctly around the work. It's perfectly true that a knurl can generally be used on any diameter because they displace material and all will be ok if it's clamped to give a decent pattern and then run along the work. This isn't always the case when a second pass is needed as per that competition I was entered into. Fortunately it was only few thou and it worked out ok. In fact the only reason it can have worked out is that there must have been a little more "depth" available in the knurl. I always aim on producing one that is reasonably smooth to the touch rather than dead sharp - they do come out like that at times though with the narrow wheels so out comes the emery cloth. The knurls I used at work tended to give that sort of feel to them anyway. I also used the same tool on a whacking great screw driver handle that we all made. Not an ideal place for a sharp pattern John - Edited By Ajohnw on 12/07/2016 12:33:20 |

| bodge | 12/07/2016 13:01:20 |

| 186 forum posts 3 photos | I can't but you can, at the top click 'my posts', choose ignored members and you will get a list you can edit (I assume). Neil Thanks,...... ( edit, it would appear so )...........b |

| OuBallie | 12/07/2016 14:19:57 |

1181 forum posts 669 photos | The Hemingway kit does as advertised. The side plates could no doubt be made deeper if needed. Geoff - Tidying Carport |

| Jon | 12/07/2016 20:29:14 |

| 1001 forum posts 49 photos | Doubt it Neil, yours is the best knurling I have ever seen by a clamp type knurler and would be happy with, well done. Know exactly how you have done it and used as would a push type by trial and error leaving part running. Do a lot of course knurling end on up to 5 1/4" dia, cant do that with a clamp type. |

| Michael Horner | 30/07/2018 19:44:56 |

| 229 forum posts 63 photos | Posted by Vic on 09/07/2016 19:20:18:

I bought a knurling tool and had the same problem, very wobbly arms. I made my own in the end which works fine.

Hi Vic Came across this whilst researching knurling tools, it looks good. Are the side pieces about 5mm thick? Going to cheat and use 2 push knurls with 0.5" shafts should be just enough metal in them to drill the holes for the pivots and the clamp. Cheers Michael.

|

| jacques maurel | 31/07/2018 15:41:33 |

84 forum posts 20 photos | Have a look at the article "machining shiny knurls" ME issues 4543 & 4545 (sept and oct 2016) J Maurel |

| Martin Kyte | 31/07/2018 16:15:55 |

3445 forum posts 62 photos | I could maybe understand the argument for a circumference that is an integer number of knurls when using single wheel knurling tools but for twin wheels the two wheels would have to be started at the right relationship to each other which is impossible to arrange. I would be interested in others comments on this. regards Martin |

| Ed Duffner | 31/07/2018 17:45:18 |

| 863 forum posts 104 photos | If you put enough pressure on when starting the operation, the knurls fall into the grooves and continue displacing those grooves. Ed. |

| vintagengineer | 31/07/2018 18:00:10 |

469 forum posts 6 photos | Knurling does raise the material and increases the diameter. It is often used as a bodge foe bearing housings that are undersize.

Also why do people put the wrong knurls on konbs. Straight knurls are for knobs that need turning and diamond knurls are for knobs that need pulling. |

| larry phelan 1 | 31/07/2018 18:00:31 |

| 1346 forum posts 15 photos | First knurling tool I bought was a simple one with one wheel which you just pushed into the work,and hoped for the best ! I soon scrapped that one [still hidden away somewhere ] and made one of the clamp type,with two wheels. It,s not very pretty,none of my stuff is,but it works. I feel that the clamp type is a lot easier on the machine than the simpler type. But then,who am I ? Kind remarks only please !!! |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Square shanks so that a spanner could be used on it. Crazy dated exercise as every one used hex socket screws for fixings and had done for tears

Square shanks so that a spanner could be used on it. Crazy dated exercise as every one used hex socket screws for fixings and had done for tears

Register

Register Log-in

Log-in