Milling Aluminium

| Paul Lousick | 06/02/2017 01:48:25 |

| 2276 forum posts 801 photos | What is the best way to mill slots in aluminium ? Are there special cutters ? I have a sheet of 1/2" thick aluminium (aircraft grade. not sure of spec) and used my mill to cut various shapes with new, 5mm, 2 flute slot drill and a 4 flute roughing cutter. The aluminium is sticking to the cutter. Have tried cutting dry and using an aluminium cutting fluid and tried different cutting speeds and feeds. Using a vacuum cleaner to keep swarf away from the cutter. Setting up a new mill and flood coolant not installed yet. Paul. Edited By Paul Lousick on 06/02/2017 01:55:00 |

| ronan walsh | 06/02/2017 03:04:59 |

| 546 forum posts 32 photos | Flood coolant is what you want, if you watch a cnc milling aluminium at high speed the coolant blasts the swarf away so as not to interfere with the cutter. Make sure your end mills are very sharp to, or they tend to smear the surface. |

| Paul Lousick | 06/02/2017 04:56:39 |

| 2276 forum posts 801 photos | Thanks Ronan, I suspected that I needed flood coolant. I recently sold my X3 mill for an RF-45 clone, (a bit bigger), and am in the process of fitting all of the accessories including a flood coolant system which was on my old mill. Making brackets to mount the DRO at the moment. Looks like I should have fitted the coolant first. Paul. |

| Thor 🇳🇴 | 06/02/2017 05:36:18 |

1766 forum posts 46 photos | Hi Paul, As Ronan says; sharp cutters and coolant, and yes, there are special milling cutters for aluminium, see here, or here. I havent tried them myself, I just use new slot drills. Thor |

| JasonB | 06/02/2017 07:27:52 |

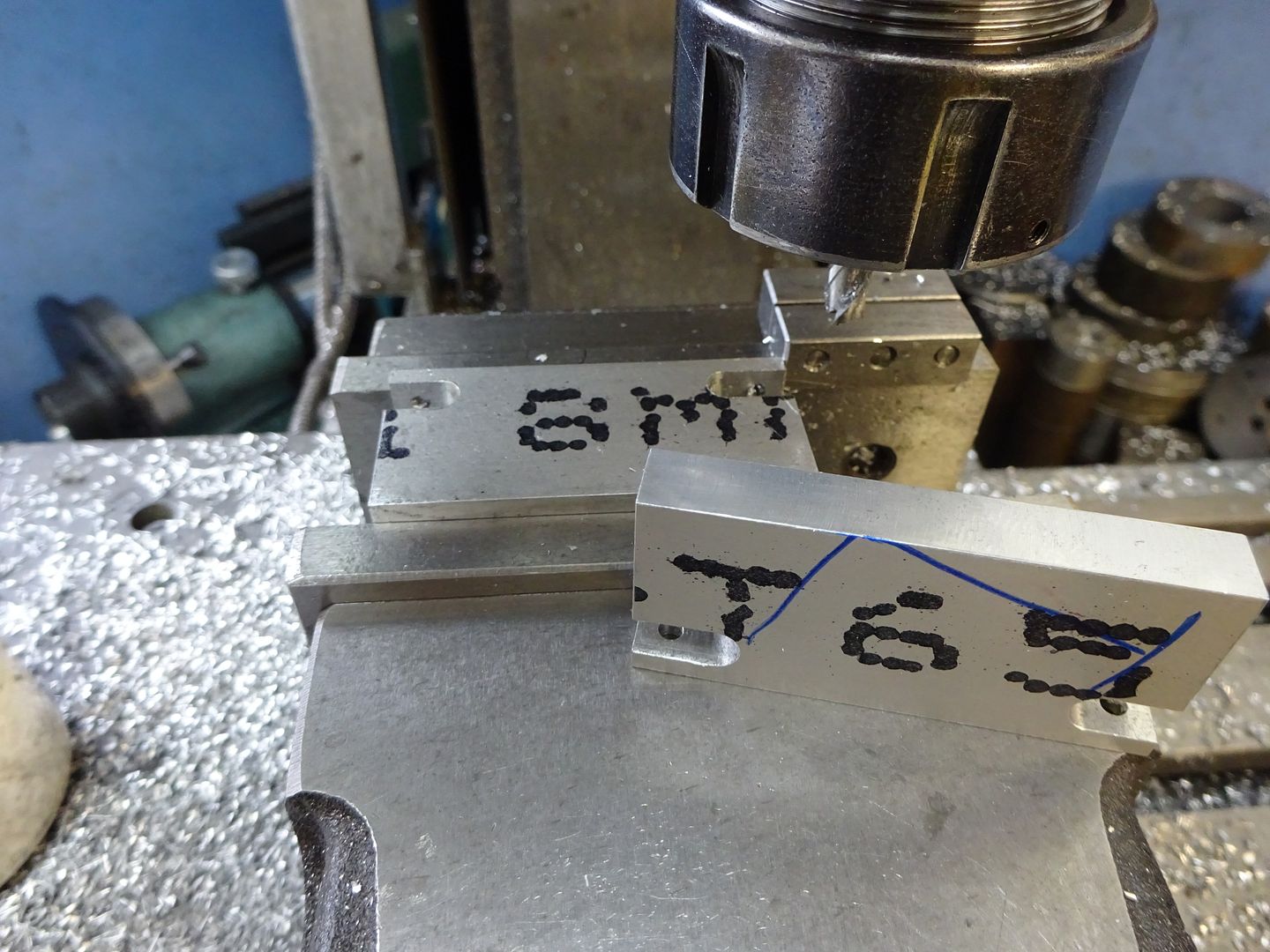

25215 forum posts 3105 photos 1 articles | Use uncoated cutters and a small amount of parafin. In smaller sizes I use FC-3 Type cutters but the HSS aluminium specific ones work well too though the length of the ARC ones can cause chatter in the smaller diameters. Couple of 6mm slots cut recently FC-3

And an aluminim cutter in action

Edited By JasonB on 06/02/2017 08:02:35 |

| Tony Pratt 1 | 06/02/2017 07:39:08 |

| 2319 forum posts 13 photos | Paul, You don't have to use flood coolant but as you found out cutting Aluminium dry is also not a good idea, try brushing on Paraffin, soluble oil or cutting oil, all will help to prevent 'sticking' Tony |

| Allan B | 06/02/2017 07:55:41 |

133 forum posts 23 photos | Hi Paul The ally sticking is where you get the metal near to the melting point, I always use flood cooling while machining any ally, I have cut it dry in the past but using small cuts to reduce the friction heat. Allan |

| John Reese | 06/02/2017 16:28:37 |

1071 forum posts | I use soluble oil in a squirt bottle. It does not take a lot prevent chips sticking. When slotting the occasional air blast will help remove swarf. I am going to try a mist coolant unit. Haven't got it set up yet. |

| mechman48 | 06/02/2017 16:38:41 |

2947 forum posts 468 photos | WD 40 is also very good for milling aluminium. George. |

| Vic | 06/02/2017 17:32:48 |

| 3453 forum posts 23 photos | The grade of aluminium alloy has a huge influence. I've only once had a problem and just accepted it was a poor grade of alloy for machining and discarded it. I do all my milling dry except sometimes for a finishing cut. |

| Tim Stevens | 06/02/2017 17:43:40 |

1779 forum posts 1 photos | Hello Paul It looks to me as though the alloy grade might be what is marked in big black letters on the metal you have. Any clue about what it said before you attacked it? Regards, Tim

|

| JasonB | 06/02/2017 17:53:35 |

25215 forum posts 3105 photos 1 articles | Tim, that's my photo and the plate is 6082 T6, HE 30 in old money and I had no problem cutting it. Edited By JasonB on 06/02/2017 17:53:55 |

| John Haine | 06/02/2017 17:56:04 |

| 5563 forum posts 322 photos | Another vote for milling dry for machinable alloys, but sometimes using a mix of cutting oil and paraffin on "sticky" stuff. Now for a theory which seems to work for me. Metal cutting is really a thermal process anyway where the shearing action of the tool causes the metal to soften 'cos it gets very hot near the tool tip - I read this in a long and erudite tome on machining methods some years back. I think a problem one gets sometimes is that the metal doesn't get hot enough to properly melt and detach itself from the tool. I have found that actually increasing cutting speed can make everything work better with aluminium, and since I started using my CNC mill I find that I'm usually turning the speed to max (~5000 rpm) on the biggest cutters I have a collet to hold, 10mm, on ali and having no problems. It will be even better I hope when I have my chip blower set up. |

| Neil Wyatt | 06/02/2017 19:07:44 |

19226 forum posts 749 photos 86 articles | The hollow in this 6082 bar is about 275mm long and 7mm deep, I chewed it out with an ARC uncoated cutter to full depth at each pass. Not the very best finish as I was just hogging out waste to reduce weight. |

| ronan walsh | 06/02/2017 19:35:07 |

| 546 forum posts 32 photos | I do find wd40 good on aluminium, but its expensive, and i cannot stand the pong. One reason i like a lot of coolant is it washes away the swarf, if you let it build up around and on the cutter, swarf can and does smear between the cutter and workpiece. |

| Stuart Bridger | 06/02/2017 20:28:49 |

| 566 forum posts 31 photos | Screwfix do wd40 for £6 per litre if you buy 5l. More expensive than a neat cutting oil, but not rediculous. |

| JasonB | 06/02/2017 20:33:36 |

25215 forum posts 3105 photos 1 articles | Paraffin about £5 for 4lts from the local petrol station, garden ctr, etc and I quite like the smell |

| ronan walsh | 07/02/2017 00:08:59 |

| 546 forum posts 32 photos | Posted by JasonB on 06/02/2017 20:33:36:

Paraffin about £5 for 4lts from the local petrol station, garden ctr, etc and I quite like the smell

Me too, we had a paraffin heater at home when i was a kid, very distinctive smell. |

| rollingbrit | 07/02/2017 01:01:11 |

| 1 forum posts | if cooling is not needed then Denatured alcohol, and rubbing alcohol can be used it will stop the build up on the cutter and will evaporate and does not leave residue behind a bit of searching and £4-£6 for 5ltrs also great for cleaning |

| John Stevenson | 07/02/2017 01:17:12 |

5068 forum posts 3 photos | I mix paraffin and ATF [ automatic transmission fluid] at 75% to 25% ratio and find you get the best of both worlds.but any light grade hydraulic oil will work, it's just that I have gallons of the stuff. Don't use a 4 flute cutter, there isn't enough space between the flutes to get the chips away given alloy being softer is cut faster. Routers that cut aluminium often use 1 flute cutters, no it's not April the 1st. These have maximum chip clearance than any cutter.

Problem with flood cooling on small hobby machines with no full guarding is you can't get enough flood. You need to wash the chips out of the cut and once you are say 10m or 12 mm deep that's a fair bit of pressure to make things messy fast.

In my new proposed hobby workshop at the new house [Tm] I plan to fit curtains to the bench mill, whatever model that is. Two / three brackets screwed to the ceiling both sides to support a length of plastic conduit with a slit in it. Into this slit will be some lengths of that black plastic DPC membrane you put on brickwork as a damp course [ because it's cheap ] This can be would up when bot in use and wound down when messy milling and it will catch the chips which will fall into a designated area to be cleaned up instead of all over the shop, in me boots and down me neck as it does at the moment.

Don't know if I can apply for a patent |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in