filing cat iron

| Martin Peck | 24/03/2012 14:53:29 |

20 forum posts | Hi there i am not really a beginner but I think this is the best place to start this thread. Does anyone know the best type of file to get through the skin on cast iron, ordinary with coarse cut, tungsten carbide grit or diamond? I am asking because I need to open up a square hole in a casting so machining is a non starter! |

| Ady1 | 24/03/2012 19:55:53 |

6137 forum posts 893 photos | Drill it with carbide File the edges square

Masonry drills have carbide tips if you don't have carbide drills Cast Iron is a doddle with the backgear engaged. Strap the casting to the saddle? Edited By Ady1 on 24/03/2012 20:04:36 |

| Martin Peck | 24/03/2012 20:04:50 |

20 forum posts | The problem is that the casting has been cored so there is already a square hole through it, just undersize. I need to get through the skin on the inside of the hole to enlarge it to its final size. |

| Ady1 | 24/03/2012 20:09:27 |

6137 forum posts 893 photos | aaaaahhh.... How big is the casting in simple terms How big is the square hole and how long/deep

I haven't done anything like that but the other guys will dive in once they get a few details. Machine a datum surface on the outside, then use a shaper with a carbide tip?? hmmm... Edited By Ady1 on 24/03/2012 20:24:03 |

| blowlamp | 24/03/2012 20:36:35 |

1885 forum posts 111 photos | Diamond files will shift anything and are quite cheap, so they're what I would use.

Martin. |

| Martin Peck | 24/03/2012 20:36:41 |

20 forum posts | The casting in question is the rear axle box for a 2in Burrell Gold Medal. It is 2 1/2 x 1 3/4 inches and the hole is just over 3/4in square x 1in long, to be opened up to 7/8in square to accept the rear axle tube. There are two of them, both identical, so I have to do it twice! |

| JohnF | 24/03/2012 22:55:44 |

1243 forum posts 202 photos | Never had this scenario but in general cast iron is easy to file but there is likely to be some crud left in the hole from the casting core so I would start with an old file. Don't assume that there is a skin--might be but there again maybe not. I agree with Martin diamond files will cut almost anything but they are slow to use, one other type of "file" you may hav seen at the ME exhibitions is the ones with carbide bonded onto a piece of sheet metal and they are considerably courser than diamond files--can't recall the trade name though. Cheers John |

| julian atkins | 24/03/2012 23:27:47 |

1285 forum posts 353 photos | Answer.... an old one! an old warding file should do. it will remove a skin, and if there isnt a skin it wont suddenly remove a large amount of cast iron, as cast iron is surprisingly easy to file. i file all the spokes on loco wheel castings, so am aware of the problem |

| Springbok | 24/03/2012 23:58:54 |

879 forum posts 34 photos | Hi More than likely there will be a "skin" but this is usually very thin once this is removed cast iron is a dream to file compared to some other metals. Built a 7.25g loco which had lots of casting some years ago and did not use anything special in the line of files. As my old dad used to say elbow grease my lad... Good luck with the burrell and keep all of us posted as to progress. Bob |

| Gray62 | 25/03/2012 00:02:27 |

| 1058 forum posts 16 photos | I think what JohnF may have been alluding to are Permagrit tools, do a google search, there are uk stockists and although I have no personal experience, I have had accounts of their durability and excellent performance. These are Tungsten Carbide, not Diamond and are available in varying grades. I have used TC tile files on cast iron and they do remove significant amounts of materiel so I would suggest that PermaGrit tools would perform at least as well. If you go down this route, please let all know of your experiences. regards CB |

| JasonB | 25/03/2012 08:12:21 |

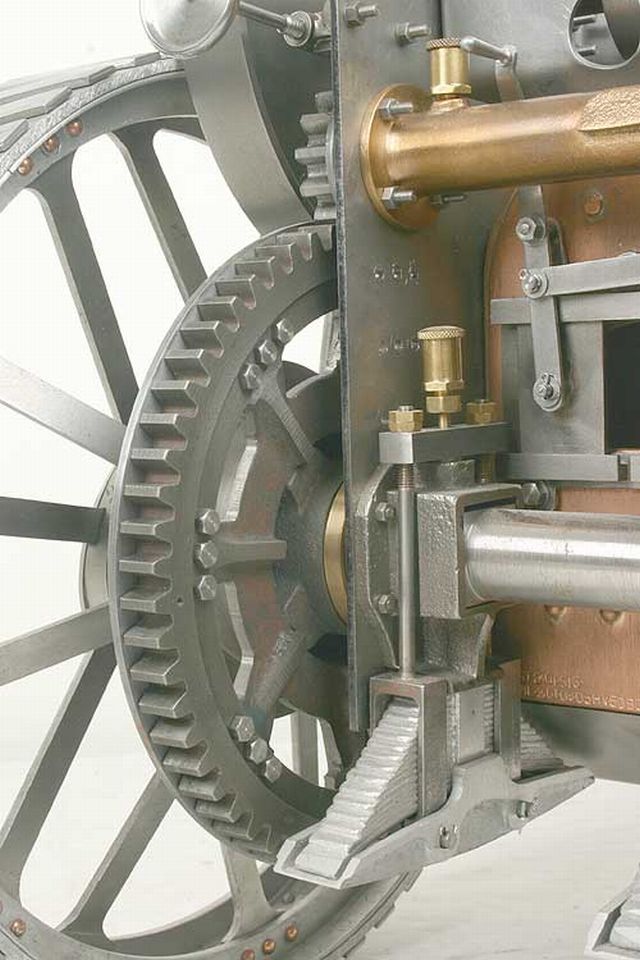

25215 forum posts 3105 photos 1 articles | Take the skin off as much as possible with a carbide burr or small grinding bit in a Dremel or die grinder then file out the corners and tidy the faces with a file. You say the part cannot be machined but why can't you mill out to the 7/8 square and then just file the corners if you don't want an internal radius. You could also knock up a tool like a slotting head and plane the corners out. I think filing alone will not give a good sliding face unless you are very good at filing or use a rest.

To help people see what you want to do, this is the part in question

J

Edited By JasonB on 25/03/2012 08:16:43 |

| chris stephens | 25/03/2012 12:53:46 |

| 1049 forum posts 1 photos | have none of you heard of a Black and Decker Powerfile? chriStephens |

| Martin Peck | 25/03/2012 20:05:16 |

20 forum posts | Success! I used diamond files to break the skin, after that it was plain sailing. Now i've just got to do it again for the second one! Just for the record, I checked permagrit's website and they only do one large flat file which is 38mm wide so no good in this instance. Thanks to all for the plethora of advice. |

| Joseph Ramon | 26/03/2012 15:54:29 |

107 forum posts | I hope you wore a face mask, or are you blowing black gunge out of your nose now? Joey |

| Jon | 26/03/2012 16:35:19 |

| 1001 forum posts 49 photos | Martin just get a 6" second cut Vallorbe flat file, easy. Many places do them. If you go for the square files they have rounded or radiused edges so cant get a sharp edge. What i would have said if seen this thread is centre existing square hole and drill out just under 7/8", plain sailing then. Square holes relatively easy, just keep an eye on what your doing. |

| Donhe7 | 27/03/2012 05:34:53 |

| 37 forum posts | How did you hold the cat and did it yowl much???

(Tongue in cheek!!) donhe7 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in