Lathe screwcutting

| Plasma | 05/03/2019 16:31:19 |

| 443 forum posts 1 photos | Hi all, I'm trying my hand at screwcutting in the lathe. I've managed to set the metric pitch right and using an inverted tool in the front tool post with the lathe running in reverse I can cut a right hand thread away from the headstock. I just seem to get quite ragged results, torn thread from or what look like multiple starts. Any advice gratefully received. I've watched loads of videos but they don't seem to help. I've tried infeed with the cross slide and with the compound slide set at 30 degrees but no big difference. I need to cut some larger threads than available with taps and dies so i have to crack this. Regards |

| John Rudd | 05/03/2019 16:45:18 |

| 1479 forum posts 1 photos | I'm no expert at screwcutting, but I would leave the tool as normal rather than invert it, run the lathe in the conventional manner and cut to a relief at the end of the thread......back to basics as they say...Set the tool at right angles to the work, with the compound slideoffset to 30 deg if its metric, adjust DoC with compound and back tool out using crossfeed.. So, Rather than blame your technique, what material are you practising on? Are you threading using an imperial or metric lathe, is the leadscrew engaged all the time or are you disengaging it? Using a thread dial indicator? ( I cant remember if the leadscrew remains engaged for m or imp....) Tool on centre height?

Edited By John Rudd on 05/03/2019 16:49:10 |

| john fletcher 1 | 05/03/2019 17:09:14 |

| 893 forum posts | I'm no expert here. When I'm cutting a metric thread I put on some feed on the top slide, zero the dial, cut the thread,. stop the lathe after cutting the thread. Next wind out the top slide and reverse the lathe manually LEAVE the lead screw engaged. .Apply some more feed and do the same again, several times. John |

| JasonB | 05/03/2019 17:31:10 |

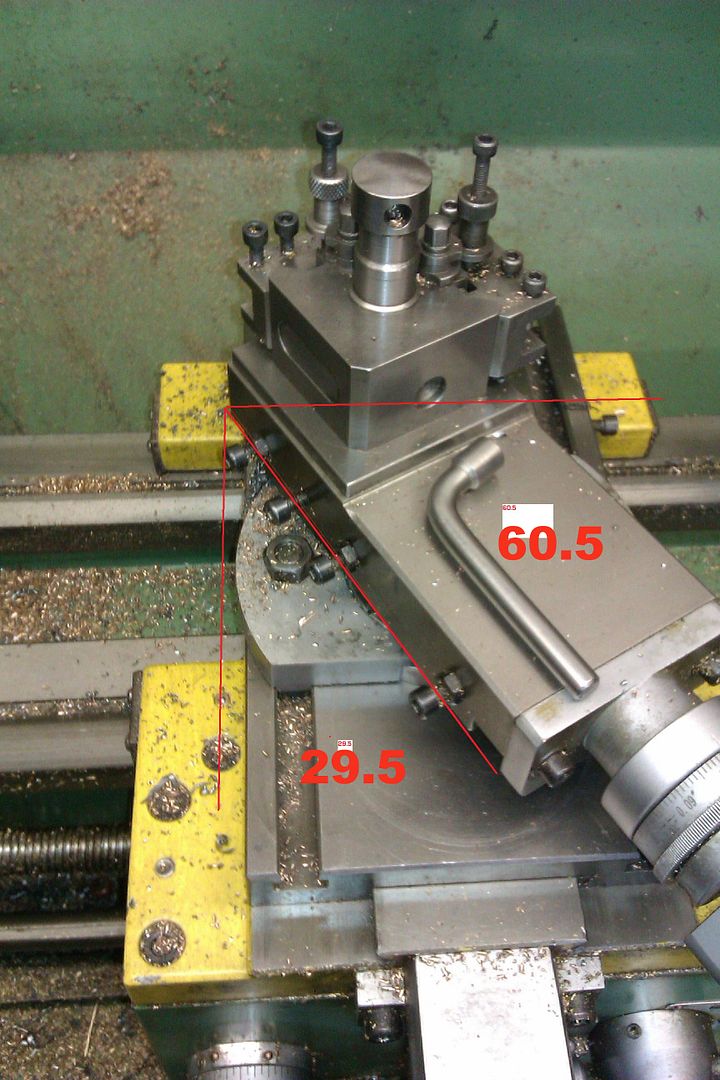

25215 forum posts 3105 photos 1 articles | two thoughts 1. If it's an imperial lathe and you are cutting metric threads don't disengage the nuts. 2. Make sure you have the topslide at 30 deg (or 29.5) to the face of the lathe not the central axis

Edited By JasonB on 05/03/2019 17:34:46 |

| John Reese | 05/03/2019 17:56:33 |

1071 forum posts | Jason B is correct about not disengaging the half nuts when cutting metric threads with an Imperial leadscrew. The same applies to cutting Imperial threads with a metric leadscrew. When cutting threads with the spindle in reverse the topslide needs to be angled opposite to what is used when cutting with the spindle going forward. The topslide should be parallel with the trailing flank of the tool, less 1/2* or so. If cutting metric threads with a metric leadscrew or Imperial threads with an Imperial leadscrew it is possible to disengage the half nuts. There are rules for which line or number on the threading dial where the half nuts can be engaged. Instead of looking them up or remembering them I choose to always engage the half nuts at the same number on the threading dial. John |

| SillyOldDuffer | 05/03/2019 18:26:58 |

| 10668 forum posts 2415 photos | Posted by Plasma on 05/03/2019 16:31:19: ... I just seem to get quite ... what look like multiple starts. ...Sounds like the thread dial is being misread, or it needs a different pitch wheel to be fitted. (Not all lathes support this.) Thread dials work best on imperial lathes doing turns per inch. Metric threads are based on pitch, which isn't quite so user friendly. On an imperial lathe doing metric the thread dial is meaningless, so always maintain thread/cutter alignment by keeping the leadscrew engaged at all times. On a metric lathe, the thread-dial instructions need careful study and the dial may not cope with all pitches. Missing pitches are made by leaving the leadscrew permanently engaged. This is the general method that always works. On a metric lathe the pitch wheel under the thread-dial engages with the leadscrew to show alignment as on an imperial lathe. Unfortunately some pitches need a different dial to leadscrew ratio, which may not be available. The thread dial on my metric WM280 has only one pitch wheel, and its thread dial can't be used to make some common threads, boo hoo. From memory my metric mini-lathe had 3 pitch wheels and did more pitches. Provided you remembered to set it up right... Usually I'll tell anyone not already dead from boredom that metric is immeasurably better than imperial. Cutting metric pitch threads on a metric lathe is so awkward it must be the kludge that proves the rule. Dave |

| Former Member | 05/03/2019 18:54:41 |

[This posting has been removed] | |

| Andrew Johnston | 05/03/2019 19:51:40 |

7061 forum posts 719 photos | Torn threads and multiple starts are probably caused by different issues. First we need to sort out the multiple starts. More information is needed: What is the OD and pitch of the metric thread to be cut? What lathe is being used, and is it imperial or metric? Can it cut the required pitch? If it can, be aware that higher spec lathes have multiple gears on the thread dial indicator - you need to use the correct gear for the required pitch Note to SoD - hooray for imperial and tpi For the torn threads, again more information is needed: Is the tool HSS or carbide threading insert? If an insert where did it come from? Hint: bang good is the wrong answer. What is the material, and where did it come from, ie, known specification or gawdonlynose scrap? A picture of the setup would be helpful. Andrew |

| Plasma | 06/03/2019 11:01:34 |

| 443 forum posts 1 photos | I knew my post lacked enough detail to cover all the bases as regards screw cutting. I'm trying to thread free cutting steel but have tried brass with better results. The reasoning behind the inverted tool is to feed away from the headstock which is safer than trying to stop before a crash. I've tried an insert tool of doubtful heritage and a hand ground HSS tool which seemed to give better results. Perhaps it's just a case of practice makes perfect. Thanks to all for their input. |

| Martin Kyte | 06/03/2019 11:11:34 |

3445 forum posts 62 photos | Are you using any cutting oil? Martin |

| larry phelan 1 | 06/03/2019 11:33:38 |

| 1346 forum posts 15 photos | Screwcutting is one of the jobs I really like doing,and although I am no expert [far from it ! ],I get fairly good results and great satisfaction from it. May I suggest that you pick up a copy of Sparey,s book,where you will find ALL the info you need,explained in very simple terms [even I could understand it ! ] Everything is explained and he mentions that even at that time,leaving the half nuts engaged for all threads was becoming common in industry. I never use the thread dial for any threads. I have cut threads up to 2 1/4 " 8 tpi without any trouble,left and right hand. Sounds like you are missing your start point each time,also,no need to invert the tool,works OK right way up. Tool was nothing more than HSS,ground by eye to form. Give it a try,it will come to you. |

| Andy Carruthers | 06/03/2019 11:43:57 |

317 forum posts 23 photos | One item not mentioned here - I am no expert and you probably know this - is depth of cut which for Metric is 0.6134 * pitch with 60 degree tool |

| Chris Trice | 06/03/2019 11:47:20 |

1376 forum posts 10 photos | Larry, I think the point of the inverted tool was because Plasma was cutting away from the chuck rather than towards it. |

| AdrianR | 06/03/2019 13:53:57 |

| 613 forum posts 39 photos | One draw back of the inverted tool is that the cutting force is upwards. This would be lifting the saddle instead of pushing it down. You would need a robust machine and well adjusted gibs. That could explain the poor cutting as your tool bit will be jumping up and down. |

| peak4 | 06/03/2019 13:57:42 |

2207 forum posts 210 photos | Posted by Chris Trice on 06/03/2019 11:47:20:

Larry, I think the point of the inverted tool was because Plasma was cutting away from the chuck rather than towards it. Indeed so, and it's probably also worth mentioning, that if Plasma wants to continue with that method, offsetting the top slide needs to be at 29.5° the other side of the cross slide handwheel. i.e. the cut is put on the leading, rather than the trailing edge of the tool. I've actually done similar jobs with the lathe in reverse, but using an internal screwcutting tool on the rear side of the work, so you can see the cut in progress. Bill |

| Jon | 06/03/2019 14:40:12 |

| 1001 forum posts 49 photos | Think most are trying to baffle him, start logically keep compound 90 degrees on and do it the way the pros do. Rest as Andrew said yesterday.

|

| John Reese | 06/03/2019 19:36:42 |

1071 forum posts | Two things I do to help prevent tearing: Use a sulfur based cutting oil. The dark cutting oil used for pipe threading is excellent. Grind some top rake on your tool. This is especially helpful on gummy materials. On-edge carbide threading inserts are available with positive rake. |

| jason udall | 06/03/2019 19:46:02 |

| 2032 forum posts 41 photos | Err just checking....when you inverse tool.....did you check tool height.... don't ask |

| Phil Whitley | 06/03/2019 19:54:54 |

1533 forum posts 147 photos | I think AdrianR has got the problem, my Colchester has no facility to adjust the saddle fit to the bed well enough to cope with an upward cutting force There is play and you can lift the saddle very slightly, so it certainly would not cope with this, are the half nuts loose or worn?, could be many things, what sort of lathe is it? Give us a clue! |

| JasonB | 06/03/2019 20:15:27 |

25215 forum posts 3105 photos 1 articles | Strange how everyone and their dog seems to suggest inverted parting tools when the subject comes up but then says it won't work for threading? I' quite often turn large flywheels with an inverted boring bar where load is far greater and get perfectly good results so don't think that's an issue unless the lathe is really worn |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in