Step blocks and clamps

| Ajohnw | 14/08/2015 21:06:30 |

| 3631 forum posts 160 photos | Every time I mill something with clamps I have mixed feelings about the clamps I have. I really should get some step blocks but while looking around I saw these clamp plates that can be used directly on a step block. Any one tried them? I'm happy the blocks with normal clamps are ok so can't see why these wouldn't work out. John - |

| Neil Wyatt | 14/08/2015 21:28:15 |

19226 forum posts 749 photos 86 articles | That's the sort that came with my big clamping set, I use them with no problems - although they can be tricky to set up as they can take a lot of space and have 'big noses'. . I've got the 12mm slot 58-piece set here: www.arceurotrade.co.uk/Catalogue/Workholding/Clamping-Sets (Except in red!) Neil |

| Bob Rodgerson | 14/08/2015 21:38:15 |

| 612 forum posts 174 photos | John, I have three different sets of these and I find them invaluable. I have heard that the tee nuts on some of thesets have been made with what may be a cast material and are prone to breakages of the tee nuts but I have had no problems with any of mine. Bob |

| Jim C | 14/08/2015 21:43:40 |

76 forum posts 4 photos | John, As Neil says, they are tricky to set up but they work really well. As with all clamps make sure if you can that the distance from the stud to the workpiece is less than the distance from the stud to the heel of the clamp. Also watch out for the stud bottoming in the T slot. |

| Ajohnw | 14/08/2015 22:53:11 |

| 3631 forum posts 160 photos | The only problem I could see is the limited angle range to keep the steps locked together with no chance of slipping. Neil makes a point though. The one is the shot are 25mm wide - how wide are the arc ones? I would be looking for M8 - m10 slot for my dore westbury. John - |

| Ian Hewson | 15/08/2015 00:15:32 |

| 354 forum posts 33 photos | SBought a set from Arc last week after years of looking in the scrap box and bodging clamps etc, worth their weight in gold! Should have got them years ago and spent my time looking for the other bits and peices that disapear when you want them. Spent ages looking for the faceplate angle plate that vanished after a clear up, only found it after turning the faceplate round, still on from the last job ages ago. |

| Paul Lousick | 15/08/2015 00:42:45 |

| 2276 forum posts 801 photos | Hi John, Not sure of what you mean by " limited angle range to keep the steps locked together with no chance of slipping". I use my clamp set all of the time and have never had one slip. A must have if you are mounting jobs on the mill. They have M10 bolts(screws ?) and has a set of blocks which can hold items up to 90mm high. It comes with a range of bolts of varying length up up 180mm and some extra long nuts for joining two bolts together. Spacers can be positioned under the step blocks if they are not high enough. Paul. Edited By Paul Lousick on 15/08/2015 00:43:43 |

| Enough! | 15/08/2015 01:02:03 |

| 1719 forum posts 1 photos | Don't get too hung up on the "tricky to set up". Once you've used them a bit, it isn't bad. On a small mill, be careful the step-block isn't over hanging the edge of the table ( or the edge of the land in the middle where the slots are) by more than a little. Too much and the whole shebang can suddenly collapse under the cutting loads. If it looks safe, though, it probably is. If necessary, a large piece of plate under the step-block can bridge some of the gaps. To be honest, my first reaction was "what else would you use" because I've used these since day-1 on my mill. I guess there are other methods (and I use them occasionally) but clamps and step-blocks work for me 90% of the time and is my primary clamping method. Edited By Bandersnatch on 15/08/2015 01:04:26 |

| Boiler Bri | 15/08/2015 07:13:49 |

856 forum posts 212 photos | I use my set more than the vice on the Miller. They are great and you can make smaller clamp plates to use with them for tricky bits. Set of these are maybe £40 a good vice will be over a £100 |

| JasonB | 15/08/2015 07:49:23 |

25215 forum posts 3105 photos 1 articles | Like the others mine get used all the time, 10mm on the mill and 8mm on the rotary table. You need not be limited by the height of the tallest block as they can be stacked or just used ontop of other packing when needed

|

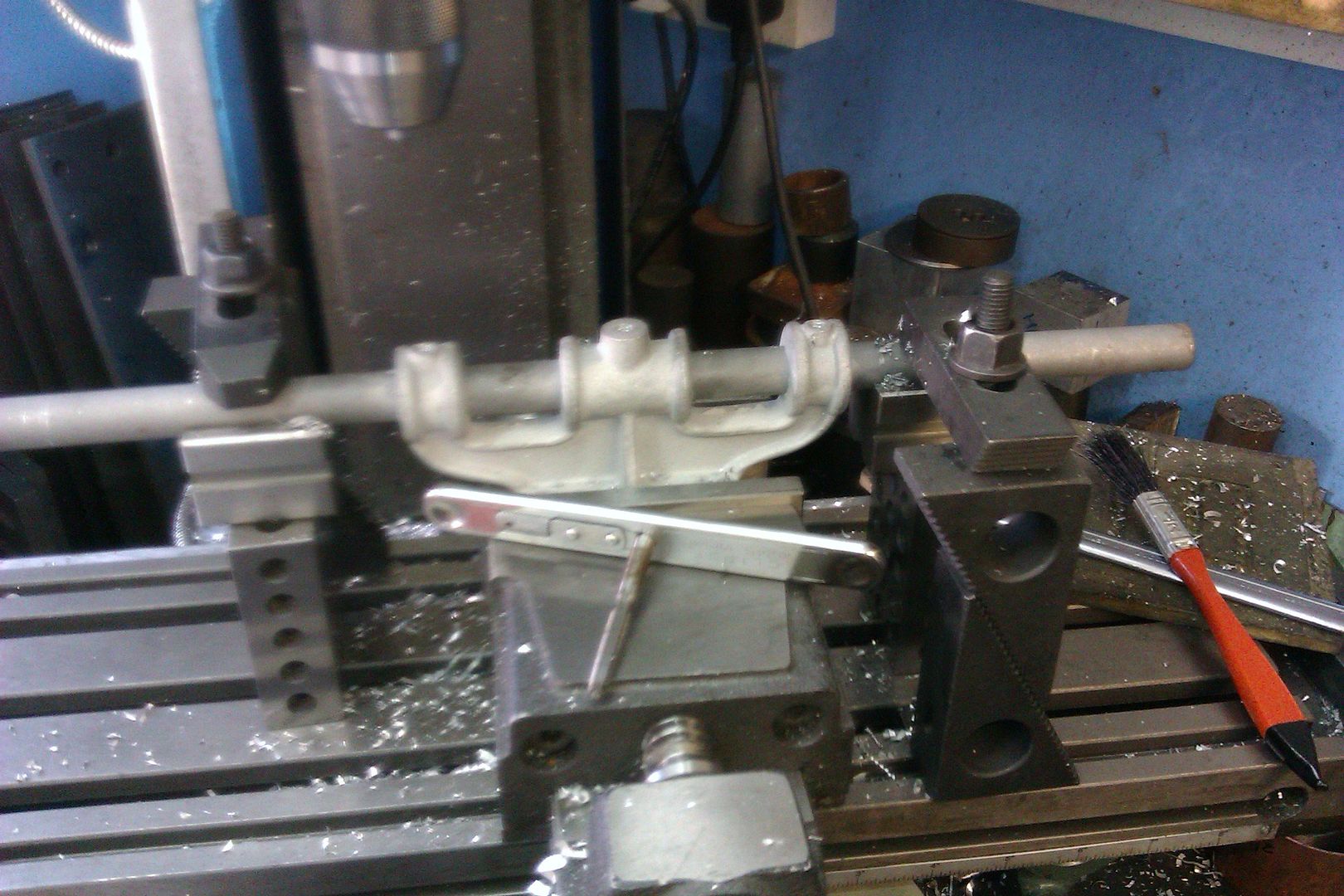

| GarryC | 15/08/2015 08:35:58 |

740 forum posts 1043 photos | Hi John I couldn't do without mine and they are very easy to use.. There are more of the same missing here in the photo as there is something set up on the mill.. (The studs are different lengths).. I think I paid about £50 for the set, may have been a bit more but not much... Cheers Garry Edited By Garry_C on 15/08/2015 08:36:17 Edited By Garry_C on 15/08/2015 08:37:25 |

| Gas_mantle. | 15/08/2015 08:51:36 |

359 forum posts 269 photos | I'm looking to buy a set very shortly and noticed these 2 :- They look very similar to me but the first is a 52 piece set for £45, the second says it's a 58 piece for £37 ? Anyone know if it's a misprint and they are the same ? Is the second one really better value or is it poorer quality ?

|

| Baldric | 15/08/2015 09:04:42 |

| 195 forum posts 32 photos | Peter, It seems that one counts the step blocks individually the other counts pairs. As to which is better I have no idea. I do use these at home and find they are great, where I volunteer we end up using an assortment of packing bits, I would get a set for there but know the bits would be distributed fairly quickly. Baldric. |

| Gas_mantle. | 15/08/2015 09:29:49 |

359 forum posts 269 photos | Thanks Baldric, It sounds like what you say about the way they count the components makes sense. I've really got to get a set, I've only had a bench drill for a week and made myself a few simple clamping components of my own to get started, they work fine for now but I could do with a 'proper' set as I'll possibly treat myself to a small mill in a couple of months. Peter. |

| Andrew Johnston | 15/08/2015 09:47:14 |

7061 forum posts 719 photos | You can never have too many clamp sets. At last count I've got 6 sets for 5/8" T-slots (3 milling machines) and 2 sets for ½" T-slots (lathe faceplates and surface grinder). I wallop the bottom of the nuts with a cold chisel to prevent the studs going through. One thing they don't like is the stud not pulling square. If there is any substantial side load the studs tend to fracture where the thread exits the T-slot nut. Andrew |

| Bazyle | 15/08/2015 10:31:22 |

6956 forum posts 229 photos | For a beginner on a tight budget there are better uses for the last £50 in the kitty as scraps and studding can be used but once past the initial mill purchase it is definitely easier to get a set. They have lots of uses outside clamping like for bearing pulling etc just make sure you get the bits all back in the holder before they go missing. |

| Ian S C | 15/08/2015 10:51:40 |

7468 forum posts 230 photos | I know what you mean Bazyle, I'm missing one of the plain nuts at the moment. When I got my mill, I thought it would be nice if they threw in a clamping set as a bit of discount, They did it, and went bust about a week later. Ian S C |

| Neil Wyatt | 15/08/2015 10:52:38 |

19226 forum posts 749 photos 86 articles | Neil makes a point though. The one is the shot are 25mm wide - how wide are the arc ones? I would be looking for M8 - m10 slot for my dore westbury.

John They do M8/10mm slot and even a less comprehensive M6/8mm slot set for very small machines. Neil |

| Neil Wyatt | 15/08/2015 10:56:41 |

19226 forum posts 749 photos 86 articles | Posted by Peter Nichols on 15/08/2015 08:51:36:

I'm looking to buy a set very shortly and noticed these 2 :- They look very similar to me but the first is a 52 piece set for £45, the second says it's a 58 piece for £37 ? Anyone know if it's a misprint and they are the same ? Is the second one really better value or is it poorer quality ? My set is red and bought from Arc some 13 years ago - it hasn't got quite as many studs and nuts, so maybe the RDG ones are like this and aren't 'fully loaded'? Neil |

| Ajohnw | 15/08/2015 12:30:03 |

| 3631 forum posts 160 photos | I have the problem of buying a retired toolmakers dore westbury. He made just about everything himself. I've managed with this type so far and I can understand why he made them - they can be rather expensive to buy. They are heat treated, 3/8 thick and 3in long. There is also some smaller stuff. As these work rather well I didn't really want to buy a set but the prices buying bits and pieces work out far more. He made a number of clamping bits and pieces for it but the studs are a bit of a mess. I could fix that via high tensile all thread. For some reason he settled on 5/16 bsf for studs. The T slots may be metric, M8 I suspect but M6 is available in the same size of T. I'd guess he had something else about and 5/16 fitted both. It's easy to make T nuts, a strip at a time and then saw them off. The reason I wondered about setting the height on the step blocks and the angle range of the stepped clamp is that I did use the blocks briefly and from memory the steps are angled so that they pull together rather than slide apart. I assume the clamps with the steps on the end are the same so past some angle they wont pull together. When the clamp isn't level spherical washers should be fitted as well but I suppose that's really only needed for rather powerful millers but suspect I might get some of those. T nuts are sold threaded all or part way through but at a couple of quid plus each where I have seen both styles offered I don't think I will be buying any, John -

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in