Metal bluing parts of the lathe

| Hacksaw | 22/12/2016 17:23:03 |

| 474 forum posts 202 photos | My mate gave me a Dixon QC but it was too tall for my S&B model M , and on putting it in my his bandsaw to whip a bit off the bottom , obviously it bounced the blade off !! So in the gas forge it went .. 10 minutes and its a nice yellow and scale forming..slow cooling...and still it bounced the blade ! Carbide mill got it shortened up , i never bothered to re harden it again . |

| Gareth T | 22/12/2016 18:16:01 |

12 forum posts | Some great advice guys, I am going to powder coat some bits, cold blue other bits and oil the rest that i cannot repaint.

|

| Harry Wilkes | 22/12/2016 20:41:27 |

1613 forum posts 72 photos | Posted by Mike on 22/12/2016 14:21:28:

Harry, this looks like oil blacking, which does work on steel. Motor oil doesn't seem to work very well, probably because of its composition these days. I've oil blacked lots of gun screws, and have found cheap supermarket own-brand margarine to be very effective, although it does make the workshop smell like a fire in a chip shop! Mike like the sound of the chip shop but not the fire bit H |

| David Standing 1 | 22/12/2016 21:27:48 |

| 1297 forum posts 50 photos | Posted by Russell Eberhardt on 22/12/2016 15:08:55:

When at school in about 1960 we were made to rub a few drops of oil into our hands on entering the metalwork shop. I still do that and have very little problem with rust. A thin film of oil on your toolpost should be all that's needed. Russell.

I've never used either oil OR barrier cream on my hands, and in 62 years I can truthfully say they have never rusted

|

| Danny M2Z | 23/12/2016 09:05:43 |

963 forum posts 2 photos | Brownells cold blue is excellent if one follows the instructions. **LINK** Degeasing is the secret. This stuff is is also great to prevent rust and the MX3 makes a very good aluminium cutting lubricant. **LINK** The grease seems to work well for gear boxes and slideways. Have you ever seen a rusty sheep? * Danny M * |

| Douglas Johnston | 23/12/2016 10:22:03 |

814 forum posts 36 photos | Posted by Emgee on 22/12/2016 15:15:42:

Posted by Douglas Johnston on 22/12/2016 14:31:33:

Rapeseed oil (cooking oil from the supermarket ) works well for heat blacking, but not a good idea for hardened objects. .. Douglas, do you mean use rapeseed oil for quenching the heated part ? Emgee Yes Emgee, I heat the part to dull red and dunk it into a container of cheap "own brand " rapeseed oil. I have never tried coating the part with oil then heating if that is what you were wondering. The oil would probably just burn off and not blacken the surface but might be worth a try. |

| JA | 23/12/2016 11:32:26 |

1605 forum posts 83 photos | This thread on bluing has come a bit early for me. In about a months time I will have more than100 special small nuts and bolts to black. The blacking is for show and must be permanent. I have given this much thought and have come to the conclusion that the hot caustic process will give by far the best results. I am trying to get a good recipe for this process and have started searching the internet. I am fully aware of the dangers of hot caustic soda. I would like to hear of anyone's experiences with the process or be told of any firms offering such a service. JA |

| MW | 23/12/2016 12:20:46 |

2052 forum posts 56 photos | So I just looked up what this is a few moments ago, the only bluing I've ever known of in engineering was the layout ink and micrometer blue! A passivating process, to protect metal.. This must be more well known among the gun community that's here. Michael W |

| Stuart Bridger | 23/12/2016 13:28:35 |

| 566 forum posts 31 photos | All my steel apprentice pieces from 1980 were phosphated. I don't remember the details of the process or whether it is practical in a home shop, but not a spot of rust on any of them |

| Harry Wilkes | 23/12/2016 14:10:09 |

1613 forum posts 72 photos | Posted by Mike on 22/12/2016 14:21:28:

Harry, this looks like oil blacking, which does work on steel. Motor oil doesn't seem to work very well, probably because of its composition these days. I've oil blacked lots of gun screws, and have found cheap supermarket own-brand margarine to be very effective, although it does make the workshop smell like a fire in a chip shop! Mike never tried oil but saw it done on a youtube vid once and the guy demonstrated the process but he did it with used motor oil ! H |

| Mike | 23/12/2016 14:51:24 |

713 forum posts 6 photos | Harry, it probably depends on the grade of motor oil - there are so many nowadays, including mineral and synthetic. Also, well-used oil probably contains tiny carbon particles, which might help. I must confess the only motor oil I have tried is fresh Castrol GTX. Maybe I've taken two clean an approach! |

| Rik Shaw | 23/12/2016 16:50:01 |

1494 forum posts 403 photos | I only tried bluing once when I did the cylinder lagging sheet for a stationary steamer. I used thinnish shim smeared with some oil I had laying around at the time and then waved the bow torch over it till I got a nice deep blue. Very easy to do and looks good on the engine. ----- Rik

|

| Gareth T | 24/12/2016 22:07:37 |

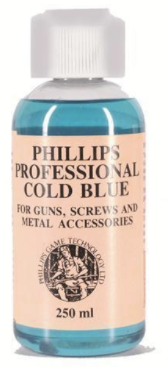

12 forum posts | Picked up some of this at the local Gun shop, I will let you know how it goes with photos.

Edited By Gareth T on 24/12/2016 22:09:23 |

| Neil Wyatt | 24/12/2016 22:18:36 |

19226 forum posts 749 photos 86 articles | I use rapeseed oil, in an empty Golden Syrup Tin for small parts, I pop the lid on if the fumes catch fire. Over repeated use it gets very thick, but melts when the hot part hits it, this doesn't seem to affect the process. Neil |

| Glyn Davies | 25/12/2016 00:42:03 |

| 146 forum posts 56 photos | In reply to JA's post about the hot caustic blacking. You can make up the salts yourself - they are all available on ebay. The recipe is 65 parts sodium hydroxide, 25 parts potassium nitrate and 10 parts sodium nitrite. Or you can buy commercial black oxide salts but the minimum quantity is usually 25kg. Mix the ingredients in a suitable steel container and add an equal mass of water. Very carefully bring to a rolling boil (it can spit while heating and hot caustic salts will cause very bad burns to unprotected skin or eyes, full IPE is essential). You need to adjust the salts/water ratio so that the rolling boil occurs at between 134 and 139 deg C. Then immerse the degreased steel components into the solution for three to four minutes (or until black), then fish out the components and drop them into a jug of cold water. The hot salts will devour aluminium before your very eyes and do not keep well - once cooled, they will absorb atmospheric moisture and grow out of their container. So once the job is done, you probably need to carefully dispose of the solution. For the toolpost parts, a rust blueing process is less hazardous, will give a very durable finish, only needs the parts heating to 100 deg C and the cost of chemicals is much less. |

| mechman48 | 25/12/2016 12:44:03 |

2947 forum posts 468 photos | Posted by Bob Rodgerson on 22/12/2016 15:27:28:

Russel, I rub Barrier Cream into my hands and don't have a rust problem either.

|

| David George 1 | 01/01/2017 18:59:27 |

2110 forum posts 565 photos | In my apprentice I used to do alcoline hot caustic bath blacking and it was just a case of dipping the parts suspended from wire in a ceramic bath of caustic soda heated from below with gas burners below then putting them in a wash bath of water and then a bath of lanolin oil. We had to wear full face head guard, a rubber apron and full length heavy rubber gloves. It is still done by some engineering firms perhaps you could find someone in your area that dose it.

David |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in