Parting tool recommendation

| Sonic Escape | 03/08/2023 15:23:23 |

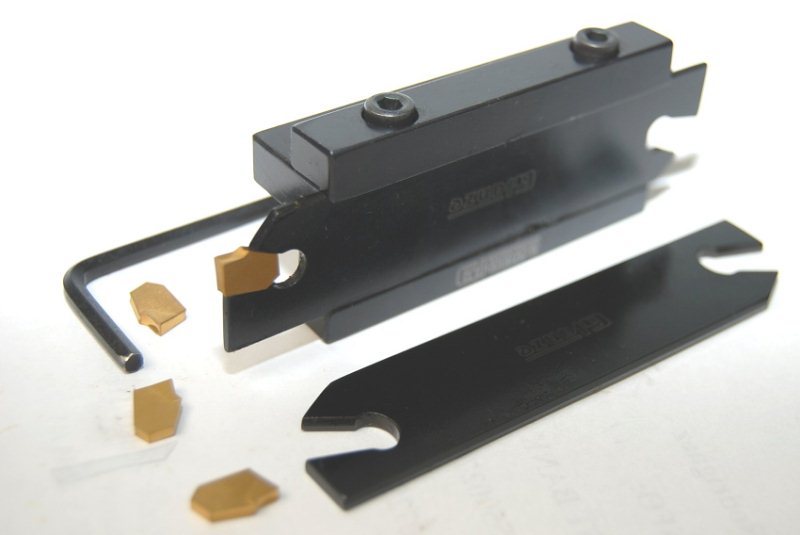

194 forum posts 5 photos | I'm looking for a good parting tool, preferably with a HSS blade. Something like this:

It should cut to a depth of at least 10mm. My tool post can hold tools up to 23mm tall. So I would avoid those 10mm tools that seems to be so common. Anybody tried this kind of parting tools? I don't see how that insert can stay there ... Edited By Sonic Escape on 03/08/2023 15:24:10 |

| bernard towers | 03/08/2023 15:33:38 |

| 1221 forum posts 161 photos | the insert stays put because its in a taper and the forces acting on it push it further into that taper. the holder and the inserts also have matching V gloves top and bottom giving sideways integrity. |

| Gary Wooding | 03/08/2023 15:45:41 |

| 1074 forum posts 290 photos | Although I've got, and use the insert-tip tool, I usually end up using the blade type with a groove along the top of the blade, like ***THIS*** |

| Sonic Escape | 03/08/2023 16:06:36 |

194 forum posts 5 photos | That is interesting! I suppose it cuts more efficient than a plain blade. |

| Sonic Escape | 03/08/2023 16:27:25 |

194 forum posts 5 photos | I had a look on other parting tools on that site, Chronos, and I found this model: It is not a HSS blade type but unlike other models it doesn't hang outside the tool post. Maybe this helps. Edited By Sonic Escape on 03/08/2023 16:27:56 |

| KWIL | 03/08/2023 16:30:17 |

| 3681 forum posts 70 photos | I use the insert type almost to the total exclusion of the plain type, works every time for me, even when used for quiye large diameters. If set correctly they are fine, but being an insert you have to make them work hard. Edited By KWIL on 03/08/2023 16:30:46 |

| bernard towers | 03/08/2023 17:08:31 |

| 1221 forum posts 161 photos | the parting discussion goes on and on but as KWIL says you have to make them work , most parting problems seem to occur with users being too tentative its one of those jobs where you have to grow a pair of !!!!!!!!. Once mastered its a joy. Edited By bernard towers on 03/08/2023 17:09:07 |

| Samsaranda | 03/08/2023 17:30:45 |

1688 forum posts 16 photos | I have both types of tool but must admit not had much success with the insert type, probably because you need to run at speed to be successful and having had some fearful lockups when using speed I am afraid to use its full potential. I now use the HSS blade type and find it very successful, you do need to make sure that there is the minimum amount of slack in your setup, not always easy on model makers lathes but from your posts it appears that you have probably got a commercial lathe. Dave W |

| old mart | 03/08/2023 18:07:39 |

| 4655 forum posts 304 photos | We use both types of carbide inserted cutoffs at the museum. I prefer the blade type as they are double ended and if you crash the other, it might be scrap in one easy go. I have holders for 26 and 32mm blades, mostly Kennametal and Kyocera, but recently have got a couple of the second type illustrated by Sonic Escape together with a box of ten inserts which are very good value in 2mm width. For smaller lathes there are blades less than 26mm deep on the market. I have an HSS type at home for my 7x12 lathe that works very well. Edited By old mart on 03/08/2023 18:09:26 |

| Harry Wilkes | 03/08/2023 18:19:15 |

1613 forum posts 72 photos | Success with parting off came when I purchased one like your first pic and mounted it on a rear tool post never looked back since to the point Ive got the insert type but never use it H |

| Howard Lewis | 03/08/2023 18:25:22 |

| 7227 forum posts 21 photos | Having had bad experiences with parting tools munted in the front toolpost, Many years ago, I made a rear toolpost forn the ML7, and for its replacement. I tried an inserted tool in the front post, on the new lathe and had dig ins which eventually distorted the holder so that the tips would no stay in place. The tool used is a very old 3/32" HSS with no top rake. At the risk of asking for trouble, dig ins are rare. Howard |

| old mart | 03/08/2023 18:31:51 |

| 4655 forum posts 304 photos |

Edited By old mart on 03/08/2023 18:33:30 |

| DMB | 03/08/2023 18:32:20 |

| 1585 forum posts 1 photos | Sonic Escape, hi, I recommend that you view website of RDG Tools. I am just a satisfied customer, having used one of their parting tools for sometime now. The holder fits my QCTP and a wedge clamp on the holder, securely holds a 3/32" thick blade. I chose the thick blade as thinner ones bend, creating concave and convex ends. John |

| Andy Stopford | 03/08/2023 19:19:19 |

| 241 forum posts 35 photos | I use the insert type 95% of the time - they're good, but resist the temptation to use cheapo inserts from ebay (other sources of dodgy inserts are available). I bought some and they mostly worked fine, but sometimes would shatter for no apparent reason. They'd probably still be an OK deal compared with more durable but expensive, quality ones, but the break up often left a fragment of carbide embedded in the cut, ready to destroy the next insert or HSS blade you tried. |

| Vic | 03/08/2023 21:10:09 |

| 3453 forum posts 23 photos | I found insert types have their uses but aren’t particularly cheap to run. I mostly use the T shape HSS ones now. Much more wallet friendly and can be used on many different materials including plastics etc. They are a available in a range of sizes. |

| Chris Crew | 04/08/2023 09:01:01 |

418 forum posts 15 photos | I am afraid I am a bit behind the times when it comes to this new-fangled tooling and a little too long in the tooth to change now. I use the good old-fashioned J&S type parting tool holders with the Eclipse type blade mounted upside down in a very rigid rear tool-post. On the odd occasion when I have 'pinged' the blade it's a two-minute job on the grinder to put the edge back on. With lots of suds pumped on it all works for me. |

| Howard Lewis | 04/08/2023 10:20:29 |

| 7227 forum posts 21 photos | A supply of lubricant, either by drip fed soluble oil, or even brush applied lubricating oil, is an enormous help. Howard |

| Mick B1 | 04/08/2023 11:22:57 |

| 2444 forum posts 139 photos | I've used these things for about 20 years now:- https://www.rdgtools.co.uk/acatalog/PARTING-SYSTEMS-FOR-SMALL-LATHES-1728.html ...in my Warco WM250V and Myford Speed 10 before that. Every so often I decide they get so worn and chewed up that I buy a new one. I recently started using my third. I won't say they always provide the user with the slickest and smoothest partoff experience, especially on grumbly steels - but they do actually work, often well, and they're cheap. Edited By Mick B1 on 04/08/2023 11:23:36 |

| Martin Johnson 1 | 04/08/2023 13:01:24 |

| 320 forum posts 1 photos | My experince with an RDG offering as in photo 1 of the OP was that the holder was fine, but the blade was not great in terms of grinding - the first 5mm or so was tapered the wrong way. After grinding that off, mounting it upside down at the back it has done some decent work, but the blade soon loses its edge. The ceramic insert style (phot 2 in OP) have a habit of running under the pip and then shattering, each occurence costing about 7 GBP. That was with coventional toolpost. I gave up when the wallet couldn't stand the strain. That is my experience. Martin |

| Bob Unitt 1 | 04/08/2023 13:38:03 |

323 forum posts 35 photos | Posted by KWIL on 03/08/2023 16:30:17:

I use the insert type almost to the total exclusion of the plain type, works every time for me, even when used for quiye large diameters. If set correctly they are fine, but being an insert you have to make them work hard.

I agree absolutely. I always used to have trouble parting-off, even with a rear toolpost. Since I changed to the insert type a good few years ago I've had much better results. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in