Pro’s and cons of owning an horizontal milling machine

| Kevin F | 09/12/2018 22:55:36 |

| 96 forum posts 24 photos |

Hello, at the moment I have a small vertical milling machine , I’m looking for something bigger and sturdier than what I have , whilst keeping my eye out for a replacement miller . I happened to find a nice looking horizontal machine .Ive thought about all the parts I make and there’s only one I can think of where I’d require the use of a vertical mill. I’m in a position where I don’t have too sell the vertical machine too fund another milling machine , but by the same token I’m a bit tight on space , what are the advantages of a horizontal machine .

|

| Andrew Johnston | 09/12/2018 23:53:09 |

7061 forum posts 719 photos | I've got both vertical and horizontal mills. I do 90% of my milling on the vertical mill (Bridgeport), along with 99% of my drilling. The horizontal mill was an impulse buy, bargain at £175. Some of it's characteristics, and uses are: It's built like a brick out house, weighs nearly 2 tons and puts the Bridgeport to shame in terms of rigidity. It's powerful (5hp) and can remove metal like you wouldn't believe. Although much heavier than the Bridgeport the axis travels are somewhat smaller, about two-thirds or a little less. I've used it mostly for gear cutting, spur gears, free hobbing of worm wheels and helical gears Other uses are cutting splines on a crankshaft and hogging out large lumps of hot rolled steel much faster than the Bridgeport I will be using it to machine the cylinder blocks for my traction engines, both to machine the block and bore the cylinders and liners, as a sort of poor mans norizontal borer Although it was an impulse buy I've more than got my moneys worth, and I wouldn't be without it. The vertical mill simply isn't rigid enough to do the sort of things I can do on the horizontal mill. Like cutting large spur gears: Or cleaning up hot rolled steel: Andrew |

| not done it yet | 10/12/2018 02:35:08 |

| 7517 forum posts 20 photos |

I have one - it’s a combo. It is used more with the vertical head, but the horizontal is handy - when I can change the head! I would like it in horizontal mode more often, but my other smaller vertical mill is limited in size (although it is handy for small parts). Small one is a Raglan and the other is a Centec 2b. So the horizontal is tiny compared to Andrew’s, but certainly not small when it comes to moving it! Question might be what do you call small? This member might be open to a deal for his mill. Second hand cutters can be relatively cheap, but new are expensive. Don’t know about sharpening, but I expect that would not be cheap. Machines tend to be more rigid. You likely would not buy a new one, so wear might be a problem. Most things that a horizontal mill will do can be done on a vertical mill (reason why nearly all new mills are vertical type?). Andrew clearly uses his far more than I will ever use mine (in horizontal). I bought mine because I needed a better mill, at the time. The horizontal with a vertical head was attractive for me. I would not change that view. It is big enough (well, almost) for me in horizontal but still limited for milling large parts in vertical mode. And it was British made. A difficult choice if you are only going to keep one. If it is at the right price, trying it,and moving it on later, may not be too expensive? Without knowing your current options and your needs, it is difficult to make a guess. Do you have a pillar drill, for instance? Not much help, am I! |

| thaiguzzi | 10/12/2018 04:23:08 |

704 forum posts 131 photos | Or keep the vertical and have a look at a shaper. I'm fortunate in that i have all 3. The vertical is prolly the most useful and used, the shaper easily the most enjoyable to use, but the horizontal does have some uses. Edited By thaiguzzi on 10/12/2018 04:23:47 |

| Paul Kemp | 10/12/2018 10:53:34 |

| 798 forum posts 27 photos | I would suggest you look out for one of these! They don't seem to come up often but they are brilliant 'little' machines with the best of both worlds. Separate motors for horizontal spindle / X axis feed and vertical head, good range of speeds as standard but in combination with VFD's as they are usually 3 phase, speed control is infinite. It's an Elliott Junior (Omnimill). Vertical head moves in and out on its overarm and swivels in two planes and can get to any area of the table. That is a 3/4' slot drill on cast iron. That is a 2" carbide tipped face mill (on steel). That is a 4DP, 56 tooth gear (its about 16" in diameter). The knee hand wheel was changed to this bigger version by the previous owner, a very worthwhile mod especially for the amount of handle turning needed on the big gear cutting. I bought this as a result of a chance conversation about this time last year. Took me about 3 months from collection just before Christmas to fettle it, sort out some VFD's to get it up and running. I still have the coolant pump to sort out (it has a built in tank in the base) but the standard pump is belt driven and when reversing the main motor you have to cross the belt, its only real down side. A kind benefactor has given me a stand alone pump which I still need to install. Since commissioning it has done a lot of work on my 6"scale traction engine on cast iron and steel components including cutting all the gears. There is nothing on the new 'hobby' machine market now that comes close to the versatility this machine offers. For its footprint its wonderfully rigid and I love it! If you can find one, grab it! Mine is not for sale!! Paul. |

| not done it yet | 10/12/2018 11:53:17 |

| 7517 forum posts 20 photos |

The machine the James has on epay looks as though it might be a universal mill - the table may swing as well - but I’m not sure of that. A definite bonus if it does swing. The riser block on mine is much longer than the one on the ‘for sale’ machine, so I could fit the vertical head permanently and swivel it ( if needed) to use the horizontal drive, by moving the riser forwards. The vertical head might need tramming in every time, but that would make things easier on the lifting front!. Unfortunately, in its present position, there is insufficient headspace to (easily/quickly) change the drawbar - it is planned to move it onto its original stand, next year, when it will have enough space.... That Elliot looks like a an even more robust machine - probably half as heavy again as a Centec? Probably pricier, too! |

| Andrew Johnston | 10/12/2018 13:01:57 |

7061 forum posts 719 photos | Posted by not done it yet on 10/12/2018 11:53:17:

The machine the James has on epay looks as though it might be a universal mill - the table may swing as well - but I’m not sure of that. A definite bonus if it does swing. ............. That Elliot looks like a an even more robust machine - probably half as heavy again as a Centec? Probably pricier, too! +1 - and the correct description. A universal mill is one where the table swivels, not one that has horizontal/vertical capability. The ability to swivel the table enables one to do useful things like cut helical gears: I wouldn't be surprised if the Elliott was cheaper than a Centec; it's getting a bit large and heavy for many home workshops. Andrew Edited By Andrew Johnston on 10/12/2018 13:02:49 |

| SillyOldDuffer | 10/12/2018 13:32:53 |

| 10668 forum posts 2415 photos | An advantage of horizontal machines for production work is that they can be set up to do gang milling. If something needs two or three parallel grooves cut in it, they can all be done in one pass by mounting 3 cutters on the machine. This capability is even more important if you're making parts by the thousand. My feeling is that horizontal mills are brilliant at what they're good at, but vertical mills are considerably more versatile. In a small general purpose workshop I guess versatility is more important than a rarely used hot performer. Must be nice to have space for both though, using the best tool for the job usually saves loads of time and effort! Dave |

| Neil Wyatt | 10/12/2018 14:04:52 |

19226 forum posts 749 photos 86 articles | In the next MEW a contributor describes how using a horizontal mill for everything was literally a pain in the neck, so he made a vertical head for his Centec. The advantage of a horizontal mill is they are very good at what they do, but vertical mills are more versatile. There's a reason why vertical mills are a lot more common. Neil |

| larry phelan 1 | 10/12/2018 14:33:09 |

| 1346 forum posts 15 photos | I seem to recall that Chester used to offer a milling machine which was both vertical and horizontal. Not sure if they still sell them,but might be worth asking. As has been said,for some types of work,they are in a class of their own,but for the small operator or shop ?? Plus,they do take up a lot of room. |

| Martin Johnson 1 | 10/12/2018 16:33:14 |

| 320 forum posts 1 photos | I was adopted by a very elderly (1947) Tom Senior M1, but he was very well endowed with horizontal arbor, vertical head (knuckle type) and a slotting head. Take a look here, particularly the engine unit build, to see if he has brought me up properly: https://www.flickr.com/photos/140734312@N06/albums/with/72157669955074511 Tom seems to punch way above his weight. Seriously, so many "model engineers" set ups are all sorts of wangles to use a vertical machine when it would be easier on a horizontal arbor. The combination machine has a lot going for it when floorspace is tight. Martin |

| Andrew Johnston | 10/12/2018 19:37:20 |

7061 forum posts 719 photos | Posted by Neil Wyatt on 10/12/2018 14:04:52:

There's a reason why vertical mills are a lot more common. As far as I know no far eastern hobby machine supplier makes a horizontal mill. So if you want to buy a new far eastern mill it has to be vertical; unsurprisingly there are then rather a lot of vertical mills about. So it's Hobson's choice, not a rational choice between horizontal and vertical. Larry: Although my horizontal mill is much heavier, more powerful and way more rigid than the Bridgeport it actually occupies less space. Andrew |

| Limpet | 10/12/2018 20:01:27 |

| 136 forum posts 5 photos | It looks like Axminster tools do a vertical/horizontal desktop mill the SU1 albeit much smaller than those shown Lionel |

| vic francis | 10/12/2018 20:25:43 |

| 125 forum posts 21 photos | Hi , that Elliot mill is very nice, and looks superior to my m1 senior due to the daylight distance ! ie from cutter to table!, however, anyone who has seen what Martin J cando on a Tom senior with regards to his steam wagon is nothing short remarkable! Van Norman is a sturdy machine , for a small workshop; very sturdy and suprise the people that use them...! ps my senior needs a new belt,inside the column... anyone know where to get that wider section belt as a link type?, pps i did skim out a car brake drums on a senior with it on a mounted faceplate! the toolpost on the mill bed! another alt way of getting a job done! regards vic

|

| Pete White | 10/12/2018 20:38:45 |

| 223 forum posts 16 photos | it depends what you do Kevin, as Neil mentioned if you like a pain in your neck, you can run vertical cutters "over the back" bigger ones that a small vertical will handle. Like the bit about, more cut for your money if buying second hand horizontal cutters. Hung my nose over Bridgeports for 40 years, should have bought one, better than money in the bank these day and you don't have to feed them. Yes agree with all said, a vertical covers most situations, except removing removing lots of metal quickly, size for size that its. |

| JasonB | 10/12/2018 20:47:36 |

25215 forum posts 3105 photos 1 articles | The far eastern makers do make horizontals but they tend to be on the large side so you would have to go via their industrial resellers rather than the hobby related ones, these Weiss ones are where Warco and Chester stuff originates and Chester's industrial site shows some of their wares |

| Neil Wyatt | 10/12/2018 20:53:03 |

19226 forum posts 749 photos 86 articles | Posted by Andrew Johnston on 10/12/2018 19:37:20:

Posted by Neil Wyatt on 10/12/2018 14:04:52:

There's a reason why vertical mills are a lot more common. As far as I know no far eastern hobby machine supplier makes a horizontal mill. So if you want to buy a new far eastern mill it has to be vertical; unsurprisingly there are then rather a lot of vertical mills about. So it's Hobson's choice, not a rational choice between horizontal and vertical. Of course I could respond by saying if there was a demand then China would supply! Secondhand prices compared to verticals seem to reflect lower demand as well. I have seen and twiddled a 'hobby' horizontal milling machine at a show, it was actually very lovely but was huge in comparison to its capacity and my understanding is that was why it wasn't a success. Search and you will find 'smaller' far-Eastern horizontal milling machines, but are more massive and therefore more expensive than vertical mills with a similar work envelope. It probably the combination of higher cost/bulk and lack of demand that explains why so few are imported. If I had the cash, space and need (I probably have least of the latter) I would get an H/V combo machine. Unlike most combo machines they seem to work well and often have a larger envelope for their 'oomph' which suits hobbyists who are generally willing to slow down and take it easy when they need to tackle a big job. Neil |

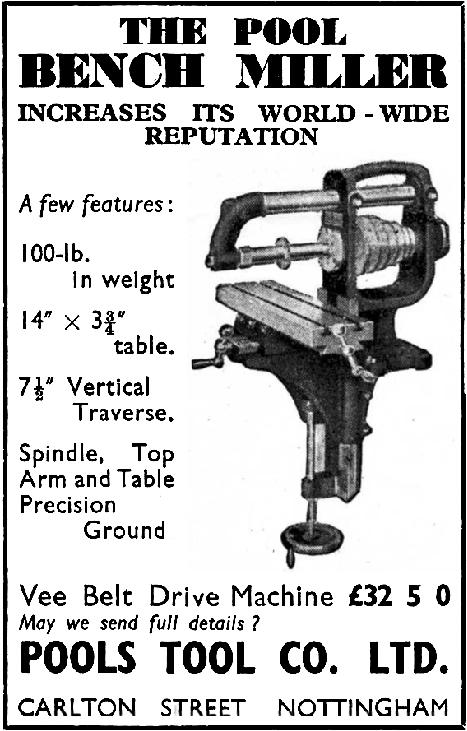

| Neil Wyatt | 10/12/2018 21:24:27 |

19226 forum posts 749 photos 86 articles | I've found four potential 'hobby' horizontal mills; a couple of them are a bit 'agricultural' although more developed than some of the 'hobby' shapers of the past, but two of them look 'smart' enough for the UK market. It would be interesting to see if enough demand could be demonstrated to encourage someone to import a batch of one? For comparison the Pools Bench Miller. looks cute until you see how much it weighs!

|

| ronan walsh | 10/12/2018 21:27:34 |

| 546 forum posts 32 photos | My Tom Senior is a universal, i have never had the need to swivel the table, but it is nice to know i have that capability if i need it. I have used the horizontal spindle more than once, and i do like the way that large side and face cutters slog through a lot of metal, without a lot of fuss, very quickly. Cutters are cheap off ebay too. |

| daveb | 10/12/2018 21:28:27 |

| 631 forum posts 14 photos | Most of the small bench mounted horizontal mills lack a backgear, that and the small motor makes them suitable for slitting saws and not much else. Daveb |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in