Simple Vice Stop

| JasonB | 20/10/2018 20:23:12 |

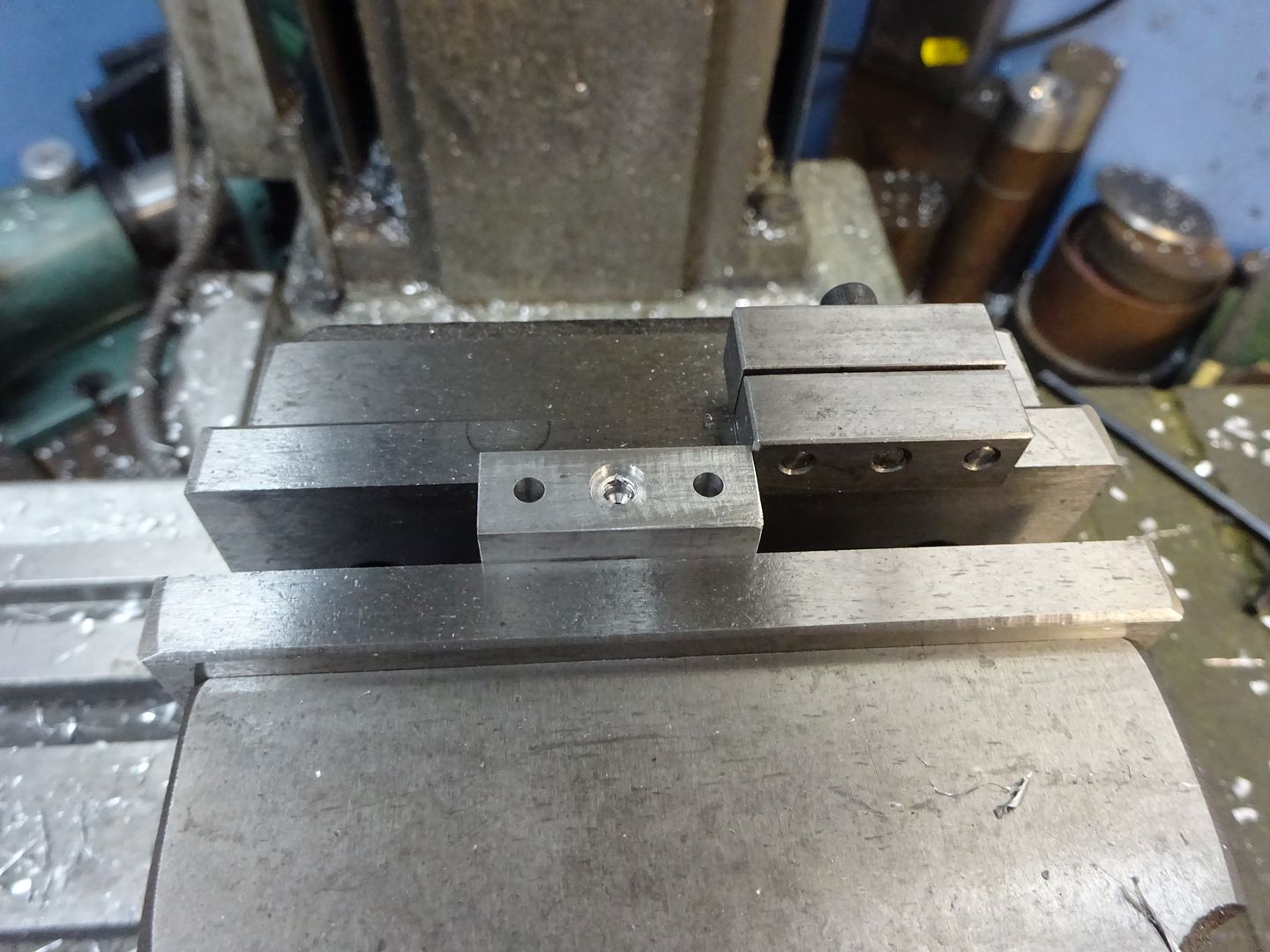

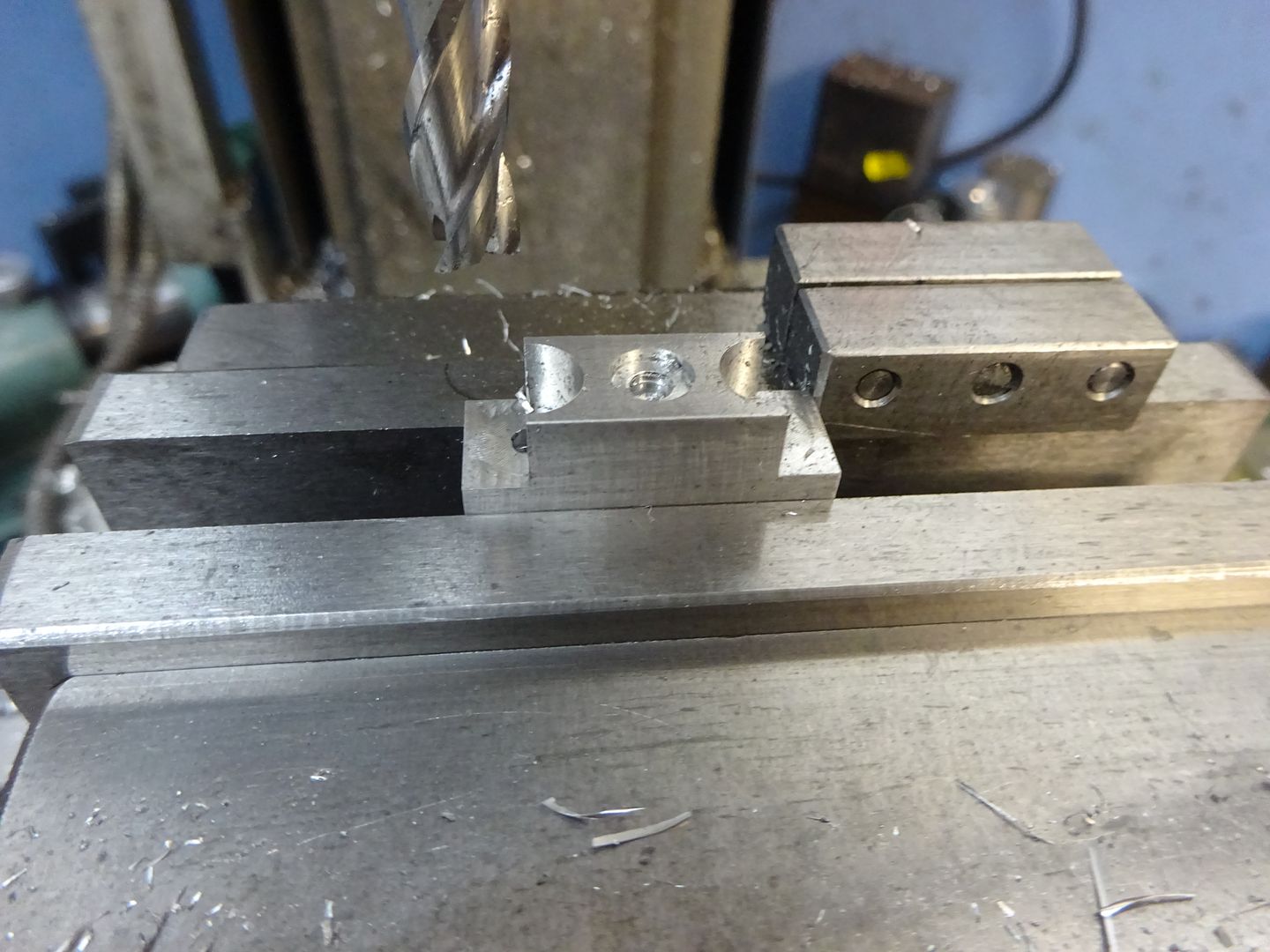

25215 forum posts 3105 photos 1 articles | I was asked in another thread for some details of my vice stop, rather than loose it in that thread I will describe it here. The two main parts of the stop are 30mm lengths of 10mm square bright mild steel, one of which has a notch milled into it leaving a small lip that hooks over the protruding edge of the vice jaw. The two halves are kept inline by two 3mm dia steel pins and a M4 cap head screw cloamps them onto the jaw. What I like about this one is that the lip is quite narrow which allows the vice to grip work down to 1.5mm thickness, there are commercial ones about for those who would rather buy but they are a bit thick, at least for some of the small work I tend to do. Construction is quite simple the 3mm holes are reamed all the way through the block with the lip but only part way through the other block, this gives a nice press fit as the rods are pushed into the tapering hole left by the end of a hand reamer. It would also be OK to just drill the holes and use something like Loctite 638 to retain the rods in one half. The central hold of the lipped block is tapped M4 and a clearance hole drilled in the other half for a M4 cap screw. If you prefer in metric then 3/8" square stock can be used together with 1/8" pins and 2BA screw.

J

|

| Ron Laden | 20/10/2018 20:55:49 |

2320 forum posts 452 photos | When Lionel asked for details of your vice stop, I thought "vice stop" what is a vice stop..? I was going to ask but thought no, I wont show any more of my ignorance, I will wait and see what turns up. I do know what its used for though, but I only know that by going back to your Jowitt build thread to find it...lol Thanks Jason that is another tool for me to make. Ron

Edited By Ron Laden on 20/10/2018 21:00:25 |

| Ian Skeldon 2 | 20/10/2018 21:04:23 |

| 543 forum posts 54 photos | Please forgive my ignorance, but what exactly do these vice stops do? I thought it was the aligning block that we used to use to quickly get a vice close up to square. The photos show this is not the case so if your don't mind Jason, can you explain where or when and how these would be used? Thanks, Ian |

| John Reese | 20/10/2018 21:11:09 |

1071 forum posts | The stop attaches to the vise jaw. It provides positive location of a part in the vise jaws. Very handy when making multiples of the same part on the mill. |

| Ian Skeldon 2 | 20/10/2018 21:17:06 |

| 543 forum posts 54 photos | Ahh a work stop, wow that's very neat, not at all like the big clumsy things we had when I was in a machine shop. Thanks for the explanation John. Ian |

| Limpet | 20/10/2018 22:47:58 |

| 136 forum posts 5 photos | Now I've seen the pictures all is clear. Something for me to make hopefully next week Many thanks for sharing Jason |

| JasonB | 21/10/2018 07:06:03 |

25215 forum posts 3105 photos 1 articles | As John says it clips onto the top or side of the vice jaw to give a repeatable X position when you have one than one similar part to machine so you only need to locate the first one rather than having to do it every time.

Edited By JasonB on 21/10/2018 10:02:00 |

| John Haine | 21/10/2018 09:25:10 |

| 5563 forum posts 322 photos | Neat! Um, X position? |

| JasonB | 21/10/2018 10:02:15 |

25215 forum posts 3105 photos 1 articles | Thanks, changed to X |

| Andrew Johnston | 21/10/2018 11:13:39 |

7061 forum posts 719 photos | Being idle i just use the left hand end of the fixed vice jaw as my reference. Andrew |

| Vic | 21/10/2018 11:51:56 |

| 3453 forum posts 23 photos | Same here. If I’m being really picky though I do use a vice stop, mines the pin type. |

| JasonB | 21/10/2018 12:12:30 |

25215 forum posts 3105 photos 1 articles | Posted by Andrew Johnston on 21/10/2018 11:13:39:

Being idle i just use the left hand end of the fixed vice jaw as my reference. Andrew Don't say that too loudly Andrew, previously when I have shown a small part being held at one end of the vice everyone and their dog got up out of their armchairs and slapped my wrists for not holding in the middle where they said it was more secure |

| Tony Pratt 1 | 21/10/2018 13:10:59 |

| 2319 forum posts 13 photos | Posted by JasonB on 21/10/2018 12:12:30:

Posted by Andrew Johnston on 21/10/2018 11:13:39:

Being idle i just use the left hand end of the fixed vice jaw as my reference. Andrew Don't say that too loudly Andrew, previously when I have shown a small part being held at one end of the vice everyone and their dog got up out of their armchairs and slapped my wrists for not holding in the middle where they said it was more secure I consider using one end of a m/c vice rather than the middle in the same league as holding milling cutters in a drill chuck, it's doable but bad practice & will eventually end in tears. Tony

|

| Andrew Johnston | 21/10/2018 13:13:01 |

7061 forum posts 719 photos | Posted by JasonB on 21/10/2018 12:12:30:

Don't say that too loudly Andrew, previously when I have shown a small part being held at one end of the vice everyone and their dog got up out of their armchairs and slapped my wrists for not holding in the middle where they said it was more secure I'd listen to the dog, but not the people. From a practical point a lot of my parts are longer than half the width of the vice. Or I'm making more than one so I use another part at the other end of the vice. Andrew |

| Chris_C | 21/10/2018 15:50:45 |

| 23 forum posts | What a neat and (so it looks!) easy to make a design. Thanks Jason, I'll be making one of those in the next few days, the one that came with the miling vice on my machine just has an M6 tapped hole so you can wind a bolt in or out a bit. Fine, but as you say, anything that is narrower than 6mm (well, it's no against the fixed jaw, more like 9 mm) and you can't use it. Edited By Chris_C on 21/10/2018 15:52:12 |

| JC54 | 26/10/2019 22:15:31 |

154 forum posts 14 photos | I know this is an old thread but many thanks Jason. I have just made a vice stop to your design/plan and really pleased with it. It is one of those simple additions to the workshop that you wonder how you managed without it.. Many Thanks, John |

| old mart | 26/10/2019 22:22:51 |

| 4655 forum posts 304 photos | I have two other types of stop, and I had never thought of this design, I must add it to my list of things to do. It will fit on the ARC vise, but the Bisons have only got about 1/2mm jaw projection

Edited By old mart on 26/10/2019 22:25:47 |

| john brown 17 | 26/10/2019 23:53:59 |

| 135 forum posts 3 photos | Thanks jason l will have to make one of them as well,will get a lot of use from that . john |

| John Haine | 27/10/2019 09:05:50 |

| 5563 forum posts 322 photos | A nice addition would be to extend the thin portion downwards, to provide a vertical fence. |

| Mick B1 | 27/10/2019 09:21:13 |

| 2444 forum posts 139 photos | Posted by Andrew Johnston on 21/10/2018 13:13:01:

Posted by JasonB on 21/10/2018 12:12:30:

Don't say that too loudly Andrew, previously when I have shown a small part being held at one end of the vice everyone and their dog got up out of their armchairs and slapped my wrists for not holding in the middle where they said it was more secure I'd listen to the dog, but not the people. From a practical point a lot of my parts are longer than half the width of the vice. Or I'm making more than one so I use another part at the other end of the vice. Andrew Yup, or a bit of stock - or anything metallic - of about the same thickness... |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in