Chilled Cast Iron

| John Purdy | 06/10/2018 18:10:50 |

431 forum posts 252 photos | A question for the metallurgists here. What is the ideal temperature/time to soak chilled iron castings to get the chilled areas converted back to gray cast iron so they can be easily machined? John |

| JasonB | 06/10/2018 18:24:13 |

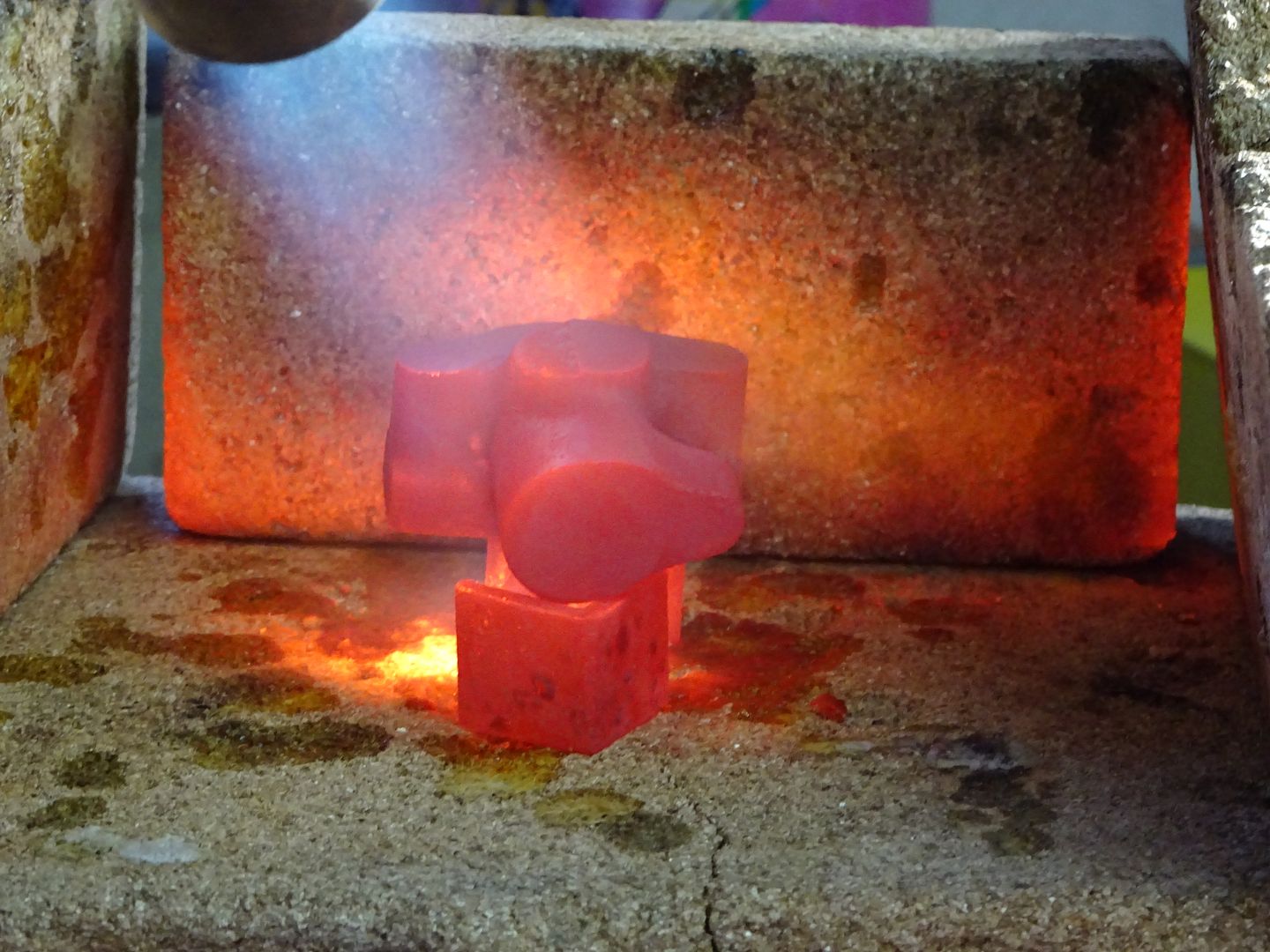

25215 forum posts 3105 photos 1 articles | This hot or a bit more

Small part like that at least 1/2hr but the bigger the part the longer it needs to soak. Then let it cool as slowly as possible. may still not be as soft as a nice bit of CI bar buy you should at least he able to drill & tap with HSS |

| mechman48 | 06/10/2018 18:31:02 |

2947 forum posts 468 photos | Hi John |

| Neil Wyatt | 06/10/2018 18:33:09 |

19226 forum posts 749 photos 86 articles | I think some foundry's soak castings for up to two days when there's a requirement for easy machining. I've often seen it suggested to put in an open fire in the evening and leave overnight to cool in teh ashes. I tried this on a flywheel and it came out like a pretzel with a broken rim Neil |

| oldvelo | 06/10/2018 20:44:51 |

| 297 forum posts 56 photos | Hi To add to Neil's posting "I think some foundry's soak castings for up to two days when there's a requirement for easy machining". The long heat soaking process give us "Semi Steel" used for pipe fittings and valves etc. Also makes arc welding to steel possible. A little aside on "Chilled Cast Iron" Apprentices at a foundry at Stockton on Tees had not heated the molds for plough shares after a late start due to a heavy night out boozing. Farmers in the area found that the Chilled Cast Iron lasted much longer and wanted more. The foundry owners questioned staff and found out about the apprentices escapades and used the process to advantage. Eric |

| mechman48 | 06/10/2018 22:37:23 |

2947 forum posts 468 photos | … 'Apprentices at a foundry at Stockton on Tees had not heated the moulds for plough shares' … |

| Guy Lamb | 06/10/2018 23:56:19 |

| 109 forum posts | For the slow cooling out of weld repaired cast iron I find agricultural/slaked lime the best thing, I don't disturb the piece until the next day and (mostly) have no visible cracks to worry about. Pre-heating (for welding) being just as important as controlled post heat too, I would say. Best Guy |

| IanT | 07/10/2018 10:40:15 |

| 2147 forum posts 222 photos | Posted by Neil Wyatt on 06/10/2018 18:33:09:

I think some foundry's soak castings for up to two days when there's a requirement for easy machining. I've often seen it suggested to put in an open fire in the evening and leave overnight to cool in teh ashes. I tried this on a flywheel and it came out like a pretzel with a broken rim Neil Well, I use my garden incinerator (galvanised type with a lid & chimney) to burn off dried wood/tree cuttings. I get a good fire going with a fairly deep bed and drop the casting(s) in gently. I then continue top up the fire for a while before letting it die back and putting the lid on. Left overnight, the next day the fire is out but the ashes are normally still hot. I've treated both wheel and larger iron castings in this way (especially if they look a bit blackened or burnt) - as well as small welded fabrications and anything from my scrap bin I think may need stress relieving. I've never had any damage to parts (apart from heat discolouration) and it does seems to help with chill spots. The only screw-up was when I tried wrapping a part in kitchen foil (I know - a stupid idea in retrospect!) to try to keep it cleaner. The foil melted and was a s** to get off completely. I don't know what temperature a wood fire can reach (the bottom off the incinerator certainly sometimes glows red hot) but I don't think it will get hot enough to damage cast iron. So whilst Neil had a bad result (open fire/uneven heating?) - I haven't so far - and will continue to use this method when it seems necessary. Regards, IanT |

| John Purdy | 07/10/2018 18:55:19 |

431 forum posts 252 photos | The reason I asked the question is that I have had chilled parts before and have tried putting them in my wood stove for an hour or so then leaving to cool overnight. That made no difference. When I made my Clarkson's compound (just finished ) there were a number of castings that had chilled areas. I placed them in my kiln and heated them to 760 deg. C (1400 F) for an hour and let them cool over night. After this treatment they machined nicely. I've now started on a ST #1 and when machining the box bed with a carbide insert end mill I found it did not machine like soft grey iron but like it was partially chilled. The machined surface was quite shiney and the noise was more of a "ting ting" on the intermittent cuts instead of the more normal "shee shee" of soft iron. So I put the rest of the iron castings in the kiln and soaked them for two hours at 760 and let them cool over-night. On machining the bed plate yesterday it was no better so was wondering if the soaking time was not long enough due to the much larger mass compared to the Clarkson castings. Jason, the colour at 760 in my kiln is slightly oranger the your picture so probably a little hotter than you show. John |

| JasonB | 07/10/2018 19:23:33 |

25215 forum posts 3105 photos 1 articles | A bit more reading seems to suggest you need a temp of about 900deg C and to let it soak for at least 1hr per inch so bigger bulkier castings need longer. A quick test for when you have reached the right temp is that the iron will no longer be magnetic so a magnet on a long stick should allow you to test it while in the furnace. having your own furnice is certainly preferable to a fire or BBQ. |

| Ron Laden | 07/10/2018 19:30:24 |

2320 forum posts 452 photos | I have never had any dealings with cast iron castings so I have to ask, what is "chilled cast iron". |

| JasonB | 07/10/2018 19:52:53 |

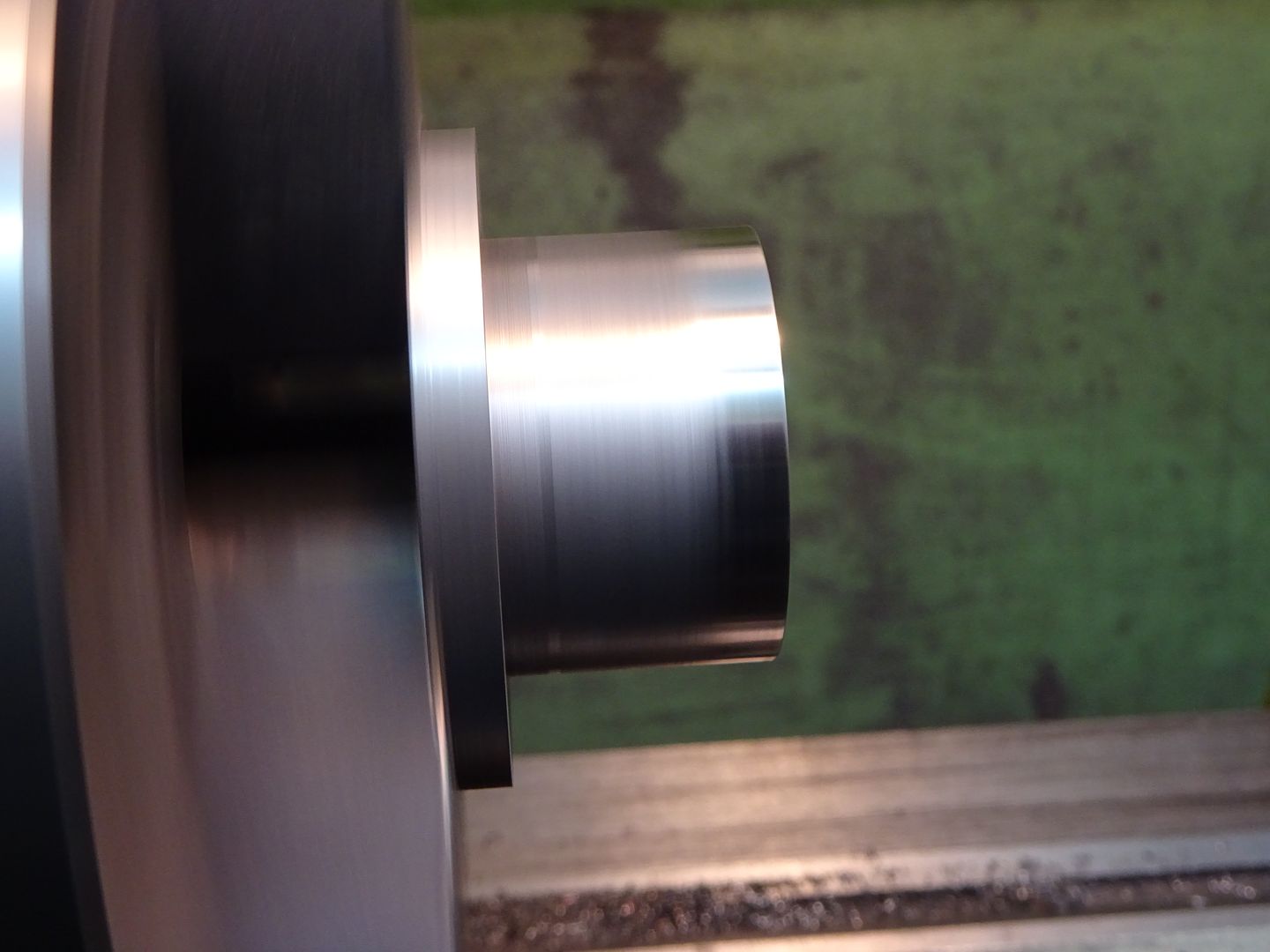

25215 forum posts 3105 photos 1 articles | If the fresh casting is cooled to quickly it will become "chilled", you mostly see it on thin castings or corners of larger ones as that is where they loose heat the quickest. The chilled area is extreamly hard and will take the edge straight off HSS tools. Flat surfaces are not too bad as you can usually use carbide tooling to mill or turn them but if you need to drill or tap a chilled area you are in for trouble. It is easy to see the hard areas as they come up bright and shiny rather than dull grey. The end of this part is a good example where the thin rim cooled too quickly

And even easier to see the shany hard end while still in the lathe

|

| John Purdy | 07/10/2018 20:09:56 |

431 forum posts 252 photos | Jason Thanks, I'll try the higher temp and see if that works any better. The thickest section in these castings are about 1" so the two hours should have been enough, but as you suggest the temp may not have been high enough. Let you know if it works any better. Ron As Jason says chilled cast iron is the result of cooling an iron casting too quickly. What happens is that when molten, the iron contains carbon in solution with the iron as iron carbide. On cooling slowly the carbon participates out as flakes of graphite (pure carbon) in a matrix of pure iron, but if cooled quickly the carbon doesn't have a chance to participate out and remains as iron carbide which is extremely hard and quite shiny being next to impossible to machine with normal HSS tooling. As mentioned above it is not always a disadvantage , being done deliberately sometimes to produce a very hard wear resistant section or part. plow shares being a case in point. This is done in the foundry by placing a large mass of metal, called a "chill" in the mold buried in the sand close to the area that is to be chilled. This has the effect of cooling that area faster than the rest resulting in being turned into chilled iron ( "white iron" ). John Edited By John Purdy on 07/10/2018 20:35:04 Edited By John Purdy on 07/10/2018 20:35:41 Edited By John Purdy on 07/10/2018 20:36:15 |

| Meunier | 07/10/2018 20:15:34 |

| 448 forum posts 8 photos | They also chill (deliberately) cast concrete surface which comes out harder than a witches wotsit. |

| Bazyle | 07/10/2018 22:18:00 |

6956 forum posts 229 photos | As Jason mentioned you have to get to a high enough temperature to get the atoms mobile to make any change happen (in less than a decade) even then atoms are lazy and take an age to move unless getting close to melting. So it is not just temperature but time too. An insight into the metallurgy (simplistic) Cast iron is actually steel with a mass of carbon flakes in it as you probably know which screws its strength by acting as stress raisers. So the behaviour you expect from silver steel, heat, chill, temper, anneal can be done to cast iron but you don't escape the problem of carbon flakes weakening it. In ME Jeynes Corner in the '60s I think gave some nice insight into small scale pre-war casting practice including adding iron 'chills' into the mould near the tips of plough shears. |

| IanT | 08/10/2018 00:28:44 |

| 2147 forum posts 222 photos | Sometimes you start to wonder whether something you have been doing is a waste of time. This is the case where you know that you have no (or very little) 'expertise' - but where you do have some 'experience' (and there is a difference between the two states). Since some of this thread seems to contradict my actual experience - I looked further. This paper gives more detail about cast irons and their properties: http://www.heat-treat-doctor.com/documents/CastIrons.pdf "The most common heat treatments applied to gray cast irons are stress relief because of non-uniform cooling of castings and annealing to improve machinability. Subcritical heating is used for both. Stress relief is done at temperatures between 1020 and 1200˚F (550 and 650˚C) without significantly lowering strength and hardness. Heating at temperatures between 1290 and 1400˚F (700 and 760˚C) lowers the hardness for improved machinability." "Ferritizing (for the most ductile microstructure) is done by austenitizing at 1650˚F (900˚C), followed by holding at 1290˚F (700˚C) to completely transform austenite to ferrite and graphite." Elsewhere I discovered that dried oak can burn at up to 1600F. Well, I'm mostly burning dried apple wood (my trees grow faster than I can cut them back) and the incinerator has vent holes around the base and there is usually a bit of a wind blowing here. So this is not like using a (slow burning) wood stove - I put a lot of wood into my incinerator during an evening and it burns fast and gets really hot - I don't know how hot - but I have no doubt that it gets things easily up to the red heat shown in the photo - and holds it there. So - I whilst I don't know if I'm getting up to 1650F/900C - I do think I'm getting them hot enough to effect some change - at least that is my experience. I'll leave it to others to worry about whether I'm only just 'annealing' and not actually 'ferritizing' - since it seems to work for me in practice. Regards, IanT |

| David George 1 | 08/10/2018 07:02:51 |

2110 forum posts 565 photos | Bedways for some lathes etc are induction hardened to prevent wear using an Hi temperature induction coil in contact with the bed shape and quick cooling. They must be age stress relieved after treatment and before final machining. David |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in