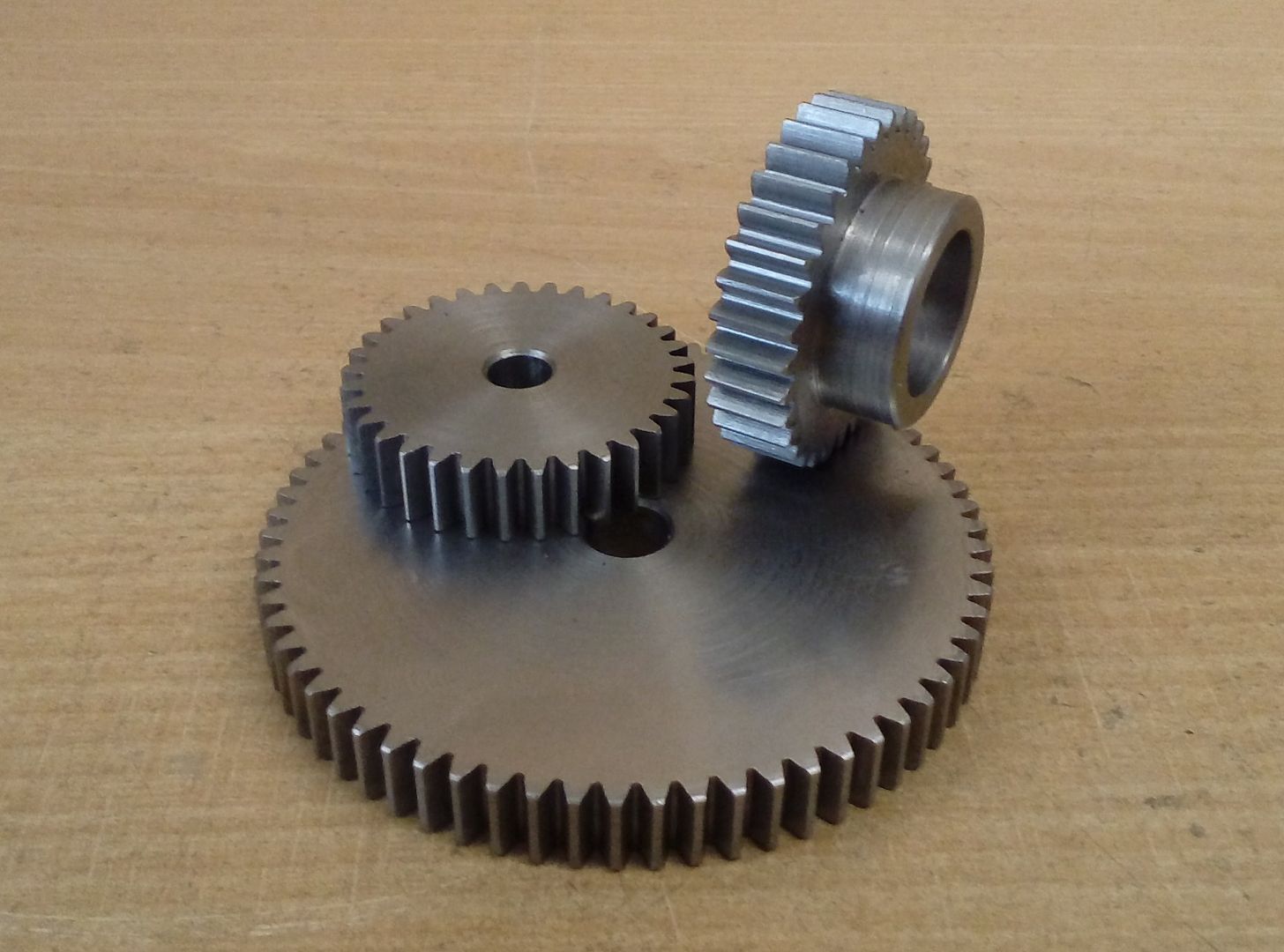

Cheap chinese Involute gear cutters

| Matt Homer 1 | 29/08/2018 14:36:08 |

| 51 forum posts 47 photos | What does the Module signify in these gear cutters. I understand the DP and pressure angles but they all seem to specify various module numbers ? Thanks Matt

Specification:

Each of Gear is different:

|

| JasonB | 29/08/2018 14:58:44 |

25215 forum posts 3105 photos 1 articles | Module is the metric system of measuring gears, DP is the old imperial way. MOD 1 is equivalent to 25.4DP Edited By JasonB on 29/08/2018 15:02:18 |

| Andrew Johnston | 29/08/2018 15:00:50 |

7061 forum posts 719 photos | Module is the "metric" way of specifing the size of gears. In simplified terms it's the inverse of DP. The precise definition is that the module is the length of the circular pitch in millimetres, so the bigger the number the larger the gear teeth. Confusingly the numbering of module gear cutters is the reverse of DP cutters. So a #8 DP cutter is for the same number of teeth as a #1 module cutter, and so on. Andrew |

| Thor 🇳🇴 | 29/08/2018 15:03:52 |

1766 forum posts 46 photos | Hi Matt, The Module system is used for metric gears, see here. Diametral Pitch = 25.4/Module, more formulas for metric gears here. Thor |

| Matt Homer 1 | 29/08/2018 15:04:42 |

| 51 forum posts 47 photos | Thanks Guys...understand....I have been watching too many US you tubers.

|

| Roderick Jenkins | 29/08/2018 15:10:41 |

2376 forum posts 800 photos | Hi Matt, Module is the metric way of specifying gears. There is a direct equivalent to DP sizes, just divide 25.4 by the Module. Thus M1 is 25.4DP and M.4 is (25.4/0.4) is 63.5. The tooth form is still involute but if you use Module gears you will need to change the design to cope with the size of gears you will cut although, e.g. 0.8M at 31.75DP is probably close enough to 32DP not to be a problem. You will note also that the cutter number is the other way round from the DP (Brown and Sharpe) notation where a #1 cutter >135. HTH, Rod Way, way too slow - sorry to reiterate the good advice above. Edited By Roderick Jenkins on 29/08/2018 15:13:15 |

| Mark Rand | 29/08/2018 17:34:17 |

| 1505 forum posts 56 photos | The other significant point is that module involute cutters are 20°PA and DP involute cutters are 14.5°DP unless marked differently |

| Bill Davies 2 | 29/08/2018 18:49:47 |

| 357 forum posts 13 photos | No disagreement with Mark, but the 20° pressure angle was common when I started my apprenticeship in 1968. The 14-1/2° is to match the older machines that many of us have. Just a comment to reinforce the need to check. Bill |

| larry phelan 1 | 29/08/2018 18:52:52 |

| 1346 forum posts 15 photos | Are those gear cutters any good ? Has anyone ever used them ? Might be interested in a set for myself All replies welcome. |

| Emgee | 29/08/2018 18:59:31 |

| 2610 forum posts 312 photos | If you are substituting MOD gears for DP then however close the tooth size may be you will need to check the centre to centre dimensions to ensure correct meshing. Emgee |

| Andrew Johnston | 29/08/2018 19:04:56 |

7061 forum posts 719 photos | Posted by larry phelan 1 on 29/08/2018 18:52:52:

Are those gear cutters any good ? Has anyone ever used them ? I used some cheap, presumably Chinese, DP rather than module, involute cutters from a well known ME supplier when I was machining helical gears to check that I understood the mathematics. I knew I'd never use the cutters again which is why I bought cheap. If I was cutting gears that mattered I wouldn't use them. My impression was they were rather more eccentric than they should be, and one had a visible wobble. Andrew |

| Roderick Jenkins | 29/08/2018 19:26:10 |

2376 forum posts 800 photos | I've had a couple of sets of small Module gear cutters from CTC and have been perfectly happy with them. Rod |

| JasonB | 29/08/2018 19:58:55 |

25215 forum posts 3105 photos 1 articles | I've used a few of teh RDG ones and they have done for the slow reving IC and steam engines. Also bought some even cheaper ones from the far east and at £5 a pop can be treated as disposable and they did seem to start loosing their edge after about 80 teeth (spaces) but the ones I did look OK to me. Expect they would last longer if use don brass rather than the steel I was cutting.

|

| Mark Rand | 29/08/2018 21:32:11 |

| 1505 forum posts 56 photos | I've also used RDG's import cutters. In my case it was putting the teeth back on the feed gears for my shaper after machining all the broken ones off and building the remains up with 98% nickel welding rod. They worked perfectly well for the purpose.

Edited By Mark Rand on 29/08/2018 21:34:02 |

| Neil Wyatt | 29/08/2018 22:02:03 |

19226 forum posts 749 photos 86 articles | I make my own single point cutters, slower but they do the job I've also used a homebrew rack form hob with success, which is as fast as using an involute cutter. Neil |

| Jens Eirik Skogstad | 30/08/2018 16:29:01 |

400 forum posts 22 photos | Module 1 is very easy to remember when you are creating the blank gearwheel also if you want to make 50 teeth gearwheel, then add 2 extra to 50 teeth will be 52 mm blank gear wheel (formula: (2+Z) x Module) and height of tooth is 2,25 mm. Module 1 is same as 3,1416 mm (PI) . Edited By Jens Eirik Skogstad on 30/08/2018 16:33:32 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in