Having trouble turning grooves

| Sherlock | 04/08/2018 17:23:22 |

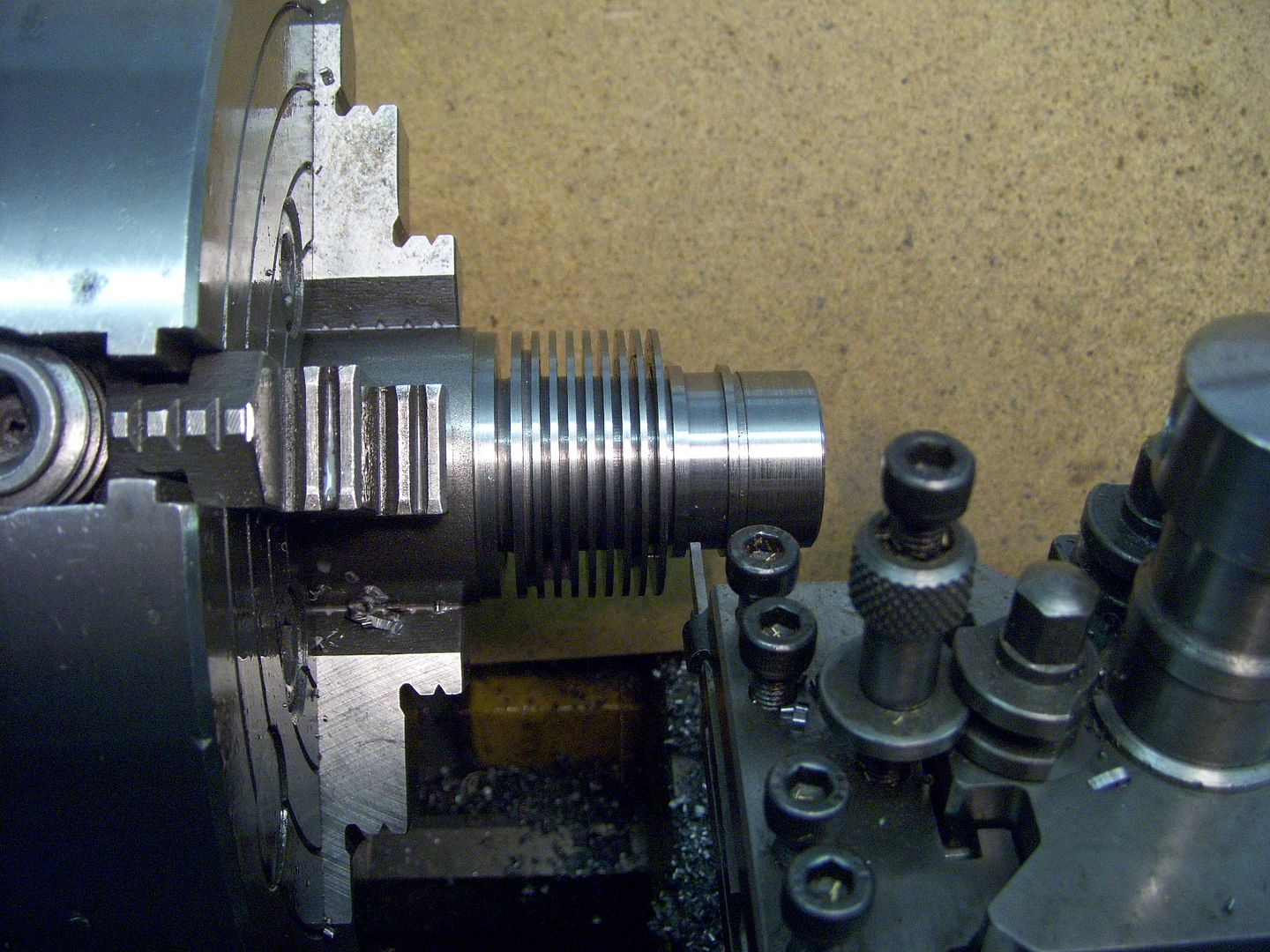

| 52 forum posts 11 photos | So I made my first cuts today on my first lathe (Cowells ME90) All went reasonably well and I managed to produce some fairly satisfactory results turning and facing some 20mm brass round. I wanted to cut a recessed groove into the brass. say 5mm deep by 5mm wide, so thought I would use a parting tool see photo below

I started getting a lot of chatter and unsatisfactory results so reduced the speed and gave a slight hone, which didn't help a great deal... I also tried this cutter, since it was thicker...

not entirely sure the actual purpose of this cutter but since it had a flat top and right angle sides, I assumed it might be up to the job, alas I was wrong.

Any ideas where I could be going wrong?

|

| Frances IoM | 04/08/2018 17:37:28 |

| 1395 forum posts 30 photos | a 1/8" HSS cutter is more appropriate + cheaper (I have a Perris v similar to a ME90) - buy a cheap grinder and grind your own eg buy a ?20 one from Screwfix etc but make a better table that the flimsy one provided tho you don't need to go to great trouble just more rigid square onto wheel with a very small gap between wheel and table - you can make up a few spacers to raise the HSS up the wheel to adjust cutting angle - once you've done it once or twice all the descriptions in various guides will make much more sense - make sure however that the cutting edge is at centre height when you mount it on the lathe Edited By Frances IoM on 04/08/2018 17:37:52 Edited By Frances IoM on 04/08/2018 17:38:45 |

| larry phelan 1 | 04/08/2018 17:38:32 |

| 1346 forum posts 15 photos | For what it,s worth [not much,perhaps ] but I have managed to cut good grooves in steel,using my rear mounted tool post,tool mounted upside down,even using form tools,which are never kind to lathes. No doubt others more experienced will be along to help put you right,just hang in there. By the way,I found a slow speed worked a bit better. |

| Maurice | 04/08/2018 17:44:52 |

| 469 forum posts 50 photos | You could try making the tool a little narrower than the groove that you require, and move it from side to side as the groove deepens. Also, I had a similar problem a while ago on some rather "odd" brass, and found that a little negative rake helped a lot. |

| JasonB | 04/08/2018 18:22:51 |

25215 forum posts 3105 photos 1 articles | It's not the best photo but the 1.5mm blade does look a bit blunt to me. You should have no problem with one of those even on the smaller lathes an an easy material like brass. Slide the blade back into the holder a bit more to reduce the distance from the tool post as much as possible. The wider tool will put quite a load on the Cowells so I would expect some chatter from that. |

| mechman48 | 04/08/2018 19:10:14 |

2947 forum posts 468 photos | On enlarging the pic it looks as though the 1.5 mm blade is dull / has a radius on the cutting edge which is where I assume you mean ...' |

| Dick H | 04/08/2018 19:11:37 |

| 141 forum posts 1 photos | I have the same parting off tool and a small Proxxon PD230 lathe which I use for making clock bits. It´s a matter of feel for speed and how fast to feed. Sometimes it will scream a bit but the finish is OK. - one more vote for sharpening the blade and reducing the over hang, - also make sure the tool is set a little below centre. - |

| Mick B1 | 04/08/2018 19:16:49 |

| 2444 forum posts 139 photos | I think you've got too much protrusion on your parting tool in pic 1. The game is usually to set it accurately to centre height, minimum tool protrusion to reach depth or cut the piece off, as close to the chuck as you can get away with, about half nominal surface speed for starting, a sharp tool kept well into the job and maybe a spot of oil. |

| larry phelan 1 | 04/08/2018 19:19:06 |

| 1346 forum posts 15 photos | Like I said,loads of expert help out there. Give it a bash ! |

| Sherlock | 04/08/2018 20:39:24 |

| 52 forum posts 11 photos | Thanks guys, some really great advice to get me going there, I actually have a 1/8" cutter blank that came with the lathe so I will grind that at some point. I think you are correct about too much protrusion as there was a lot of flex. Thanks for the explanation of WHY tools need or rather recommended to be set centre height as well mechman. Every learning material I have read states to set it centre and as daft as it may seem I never knew why as no one explained it, but now it makes sense. That smaller parting tool actually has a side rake angle, Does it need that? or can I grind it off? I only ask because when I tried to make the groove I could get a square edge on one side (left) then the other (right side) was obviously tapered because of that rake ground in the tool.

|

| Emgee | 04/08/2018 20:48:54 |

| 2610 forum posts 312 photos | Steve, best not to have any angle on the front when grooving, even if parting if excessive it can cause the blade to cut towards the point giving a concave/convex cut. Emgee

|

| Dave Halford | 04/08/2018 21:01:07 |

| 2536 forum posts 24 photos | I would blame the parting tool holder, with that overhang there looks nothing much to stop the cutting edge pivoting on the front and lifting the back edge as the clamp looks very flimsy. Side rake is to give clearance |

| Simon Collier | 04/08/2018 22:41:21 |

525 forum posts 65 photos | I agree with Jason, the tool looks blunt, in fact the cutting edge looks rounded. You are no stoning the cutting edge by mistake by any chance? |

| Sherlock | 05/08/2018 02:01:26 |

| 52 forum posts 11 photos | I was trying to just hone the front face, but there is definitely a good chance I did a bad job it was slightly tricky for me trying to maintain the compound bevel angle that was ground on it with such a narrow edge. |

| JasonB | 05/08/2018 07:07:22 |

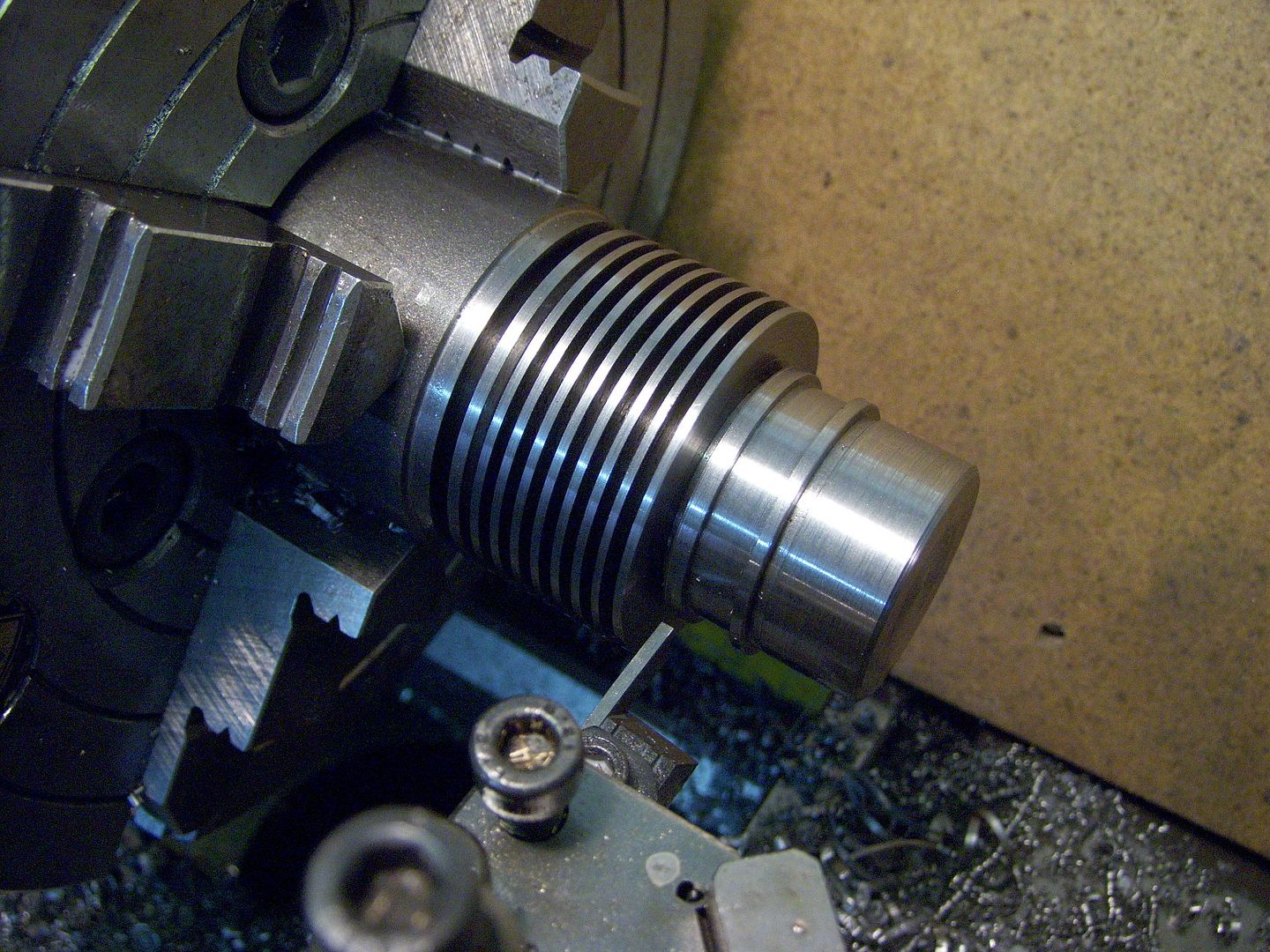

25215 forum posts 3105 photos 1 articles | Don't think there is much to blame with the tool holder, probably mor rigid than the little Cowells. As the others have said grind the end straight across which will also help prevent it wandering sideways, make your groove with a plunge cut at each end to define the width almost to depth, plunge out the waste in teh middle also almost to depth then move the tool from side to side feeding in a thou or two at a time. Same tool but a bit of 40mm EN1A did all thos efin grooves and the recess in one go no sharpening between cuts.

|

| Hopper | 05/08/2018 07:21:42 |

7881 forum posts 397 photos | Posted by Steve Sherlock on 05/08/2018 02:01:26:

I was trying to just hone the front face, but there is definitely a good chance I did a bad job it was slightly tricky for me trying to maintain the compound bevel angle that was ground on it with such a narrow edge. It looks like you need to touch it on the bench grinder, not a hone stone. Edge should be about sharp enough to cut your finger. It helps a lot, too, to lock the carriage and top slide while parting or grooving. |

| Michael Gilligan | 05/08/2018 07:37:21 |

23121 forum posts 1360 photos | Posted by Hopper on 05/08/2018 07:21:42:

Edge should be about sharp enough to cut your finger.

. ... or, to avoid getting blood on a nice little machine; sharp enough to 'noticeably drag' when sliding it across your thumbnail [with no additional weight or pressure applied] ... if it skids, it's blunt. MichaelG. Edited By Michael Gilligan on 05/08/2018 07:45:20 |

| Frances IoM | 05/08/2018 09:12:03 |

| 1395 forum posts 30 photos | you definitely don't want blood on cast iron milling tables - you can't get rid of the stain - I know thanks to (mis)handling a milling cutter! |

| Danny M2Z | 05/08/2018 14:07:19 |

963 forum posts 2 photos | Test honed edges by seeing if they will slice a sheet of copier paper. If you obtain a clean cut then they are sharp enough. When turning fins on model aircraft engine cylinders a re-cycled piece of hacksaw blade makes a useful cutting tool. Biggest PITA is making the tool holder. * Danny M * |

| Sherlock | 05/08/2018 15:11:30 |

| 52 forum posts 11 photos |

Thanks Guys, so with me not owning a grinder at the moment and confined to a kitchen table... I had to resort to a mini proxxon belt sander to grind the bevel off the parting tool. Which seemed to do a much better job than I expected to be fair.

installed the new ground tool in the holder and readjusted to shorten the protrusion as suggested nipped up the small clamp on the parting holder only slightly and the chuffing allen head broke off. Only spare bolts I have don't fit can't quite work out the size and pitch.. appears to be 3mm x 1mm pitch but the head itself was an imperial size, so either way I'm out of action until I can figure out the size and source a spare bolt or a better parting tool holder, since someone mentioned that model doesn't look too great.

Posted by Danny M2Z on 05/08/2018 14:07:19:

When turning fins on model aircraft engine cylinders a re-cycled piece of hacksaw blade makes a useful cutting tool. Biggest PITA is making the tool holder. * Danny M *

That sounds Great Danny. How does the hacksaw blade stay tentioned? Edited By Steve Sherlock on 05/08/2018 15:14:08 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in