Steve Bedair Ball Turner Build

Steve Bedair Ball Turner Build

| David Cambridge | 28/04/2017 18:12:14 |

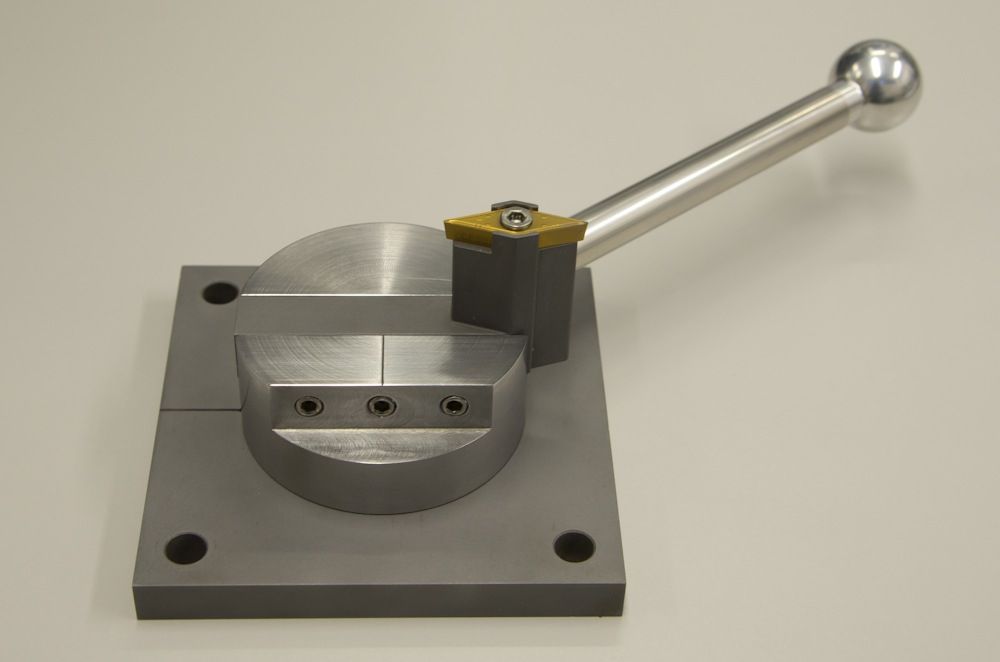

| 252 forum posts 68 photos | Hello All I’ve just finished a build of the Steve Bedair designed lathe ball turner. The video is below. David P.S. I know some of you would prefer videos without music, especially if your hearing isn’t perfect. My own personal preference is to include music, but by way of concession I have turned the volume of it down when I'm speaking.

|

| petro1head | 28/04/2017 18:59:47 |

984 forum posts 207 photos | Excellent video David This is something I am going to make for my Warco 290 lather |

| Steven Vine | 28/04/2017 19:48:17 |

| 340 forum posts 30 photos | That's top class David. Thanks for posting it. I love the way you did the video (probably less love if you had added music!) . Very enjoyable, thanks. Steve Edit: Just realised I had the speaker volume off. Edited By Steven Vine on 28/04/2017 19:51:13 |

| Neil Wyatt | 28/04/2017 20:40:25 |

19226 forum posts 749 photos 86 articles | Neat. Personally, i'd prefer a bit of 'eavy metal Neil |

| Chris Evans 6 | 28/04/2017 21:07:52 |

2156 forum posts | Nice work, I completed one loosely based on the same design about a year ago. I fitted my sliding toolpost in a dovetail just in case it may want to lift in operation but not really required. I have used it on a monthly basis making nuts and bolts with radius on the head as well as complete dome. Well worth the time to make. |

| SillyOldDuffer | 28/04/2017 21:07:56 |

| 10668 forum posts 2415 photos | Posted by Neil Wyatt on 28/04/2017 20:40:25:

Neat. Personally, i'd prefer a bit of 'eavy metal Neil Or a Steel Band... |

| Neil Wyatt | 28/04/2017 21:41:19 |

19226 forum posts 749 photos 86 articles | I must make a ball turning attachment some time. I'll get some random inserts at Doncaster. Neil |

| Martin Whittle | 28/04/2017 21:59:31 |

| 102 forum posts 12 photos | Very impressive indeed, you have convinced me that I have to make one! Yet another one of many projects for my round tuit list But thanks David - I shall have fun! Martin |

| JasonB | 29/04/2017 07:24:02 |

25215 forum posts 3105 photos 1 articles | Nicely made and a good video too. For anyone thinking of making one who can see large concave work in their future then the "post" can be made double sided

|

| Chris Evans 6 | 29/04/2017 09:06:13 |

2156 forum posts | Good tip Jason, I did make mine double sided. A friend was so impressed with it I had to make one for his lathe. |

| Vic | 29/04/2017 10:37:55 |

| 3453 forum posts 23 photos |

This is mine, I chose a slim insert to give good access.

Like some others I also put a bearing in the bottom of mine.

|

| Nick_G | 29/04/2017 11:03:11 |

1808 forum posts 744 photos | . Excellent.

Nick |

| mechman48 | 29/04/2017 13:44:55 |

2947 forum posts 468 photos | Super job Dave, well done. |

| Adam Phillips | 29/04/2017 13:59:09 |

47 forum posts | Very nice clean and simple work thank you David |

| Brian H | 29/04/2017 14:48:47 |

2312 forum posts 112 photos | I'm not hard of hearing, I just find the music VERY irritating and unnecessary but if I turn it off I cannot hear the commentary. How about doing two versions? one with and one without. Brian |

| petro1head | 30/04/2017 09:22:26 |

984 forum posts 207 photos | Posted by JasonB on 29/04/2017 07:24:02:

Nicely made and a good video too. For anyone thinking of making one who can see large concave work in their future then the "post" can be made double sided

Jason can I ask you for some sizes please. Its the top of the tool holder. What size is the piece between the two tools inserts? How much does the insert overhang the tool holder and what size is the thread for holding the tool? |

| JasonB | 30/04/2017 13:24:31 |

25215 forum posts 3105 photos 1 articles | 2.5mm between inserts The bottom of the insert matches the shape of teh post so it is only the 7degree angle of the insert overhanging M2.5 thread, best to put an insert into position, locate its ctr and then move 0.1mm towards the central divider and then drill your hole this mill mean the screw pulls the insert tight against the central divider Drawing, click to make bigger. The 40.64 is OK on my machine but may need adjusting on yours to set the insert on ctr height. |

| petro1head | 30/04/2017 15:29:00 |

984 forum posts 207 photos | Thats great Jason, thanks |

| petro1head | 30/04/2017 19:37:25 |

984 forum posts 207 photos | So far so good, have made the tool holder up the point of putting the 4 30deg angles. Just wondering whats the best way to do this. I was going to mount the work in the vice and then rotate it 30deg but is there a better way? |

| JasonB | 30/04/2017 19:50:40 |

25215 forum posts 3105 photos 1 articles | From the rather agricultural finish on mine it looks like I did it on its side and angled it 30deg. I actually took the pic earlier to show how little the insert overhangs I can't quite remember how I machined it but would say your best bet is to do the top first cutting the two lower areas for the insert to sit on then drill and tap the holes. Blue the seat, screw on an insert and then scribe a line along the two edges. You can then machine the angled faces back to the scribed line as it is not ultra critical. Edited By JasonB on 30/04/2017 19:54:11 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in