Slotting a change wheel bore

| Andrew Tinsley | 08/12/2016 14:44:22 |

| 1817 forum posts 2 photos | Going through an old cupboard, I found a rusty heap of change wheels. It is an odd collection as nowheel has the number of teeth on it, but for example 9-10 mm. They are the same tooth size as Myfords and also thickness ties up. The bore is considerably smaller than the Myford bore. I was thinking of boring them to Myford size and using them. The only snag is the keyway. How do you do this with the limited range of tools that I have at present. Basically an ML10 and most of the attachments for an ML7. I can think of ways to do the job but not with the kit I have available. I did come across a slotting device which can be made (this one for an ML7). However I have no idea where I saw it. Can anyone help? I wouldn't mind making one up, I do miss my big power shaper! Andrew. |

| John Rudd | 08/12/2016 14:57:29 |

| 1479 forum posts 1 photos | College Engineering do a casting for a slotting tool....if that helps? ( I happen to have one, its on my roundtoit list..) |

| Jon Gibbs | 08/12/2016 15:02:58 |

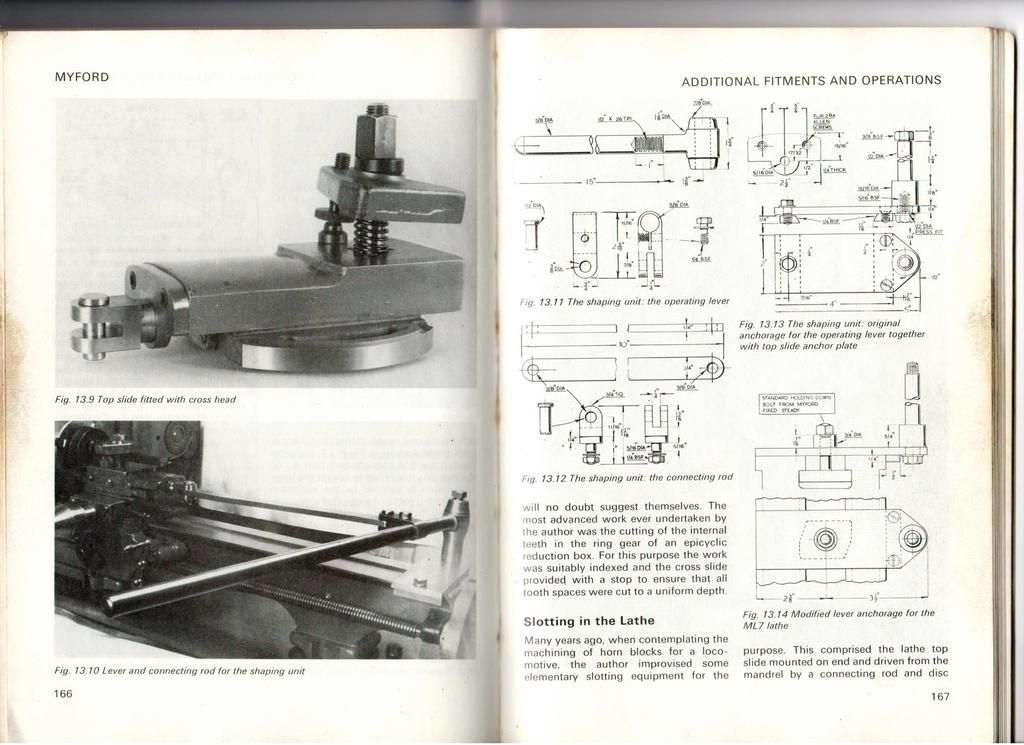

| 750 forum posts | Ian Bradley's book has several ideas but perhaps the most useful is based around the topslide without the feedscrew. The topslide is operated by a long lever...

|

| Simon Williams 3 | 08/12/2016 15:09:27 |

| 728 forum posts 90 photos | Andrew - whereabouts are you? I'm in West Gloucestershire and there is a slotter in my shed. Alternatively if you bore them and post them to me I'll slot the keyway and post them back Best Pm me if you're interested rgds Simon |

| not done it yet | 08/12/2016 15:17:31 |

| 7517 forum posts 20 photos | Handraulic shaper tool in the toolpost?

Cut a square hole in position before boring? (See Clickspring video for making one).

Pin the gears together with a pegs until such time as you can do the keyways

?

U-toob might be your friend for ideas and demos. Here is one example: https://youtu.be/yQcgLDZLMsk

Edited By not done it yet on 08/12/2016 15:21:25 |

| John Haine | 08/12/2016 15:56:09 |

| 5563 forum posts 322 photos | I had a similar problem to make a keyway in a bushing I made for a pulley when fitting 3-phase motor to my VMB. The bushing us loctited into the large bore of what was the intermediate pulley and fits the 3/4 shaft of the motor. (The pulley normally has two large ball races and runs on a stud.) I turned and bored the bush in mild steel, and at the same setting locked the headstock and mounted my 5/8 boring bar which has a dedicated mounting block on the topslide, replacing the normal Dickson holder. I made an HSS tool bit to a sort of parting profile and fitted it to the end of the boring bar at centre height, but at 90 degrees to normal orientation. Then used the rack to move the tool back and forth to cut, applying feed from the crosslide. It took a while but did the job without needing to make any special tooling (other than the cutting bit). I must have been lucky profiling the tool as the slot needed almost no fettling to fit the key. |

| Clive Foster | 08/12/2016 17:02:54 |

| 3630 forum posts 128 photos | If you have swiss or similar small files the easiest way is to drill a hole slightly smaller than the desired keyway size in the correct position before boring out. Generally the centre of the drilled hole will co-incide with the edge of the bored hole leaving an essentially semi-circular cut out. Its pretty easy to file the hole out to size so its a snug fit on the key. If you want a real nice job and have HSS blanks the right size its not too difficult to make up a sharp tool which, when set-up with its centre line on axis, will shave out the last couple or three thou to give a truely fitting keyway. I got a bunch of standard gears from HPC to make an imperial conversion set for my metric Smart & Brown 1024 and put off doing them for a year or so as I never seemed to get round to making a slotting device. Eventually I had to do one "right now" for an urgent job. Drilling and filing proved to be so easy that I did them all "right now" before getting on with the urgent job. Unless you have other work for it making a slotting device for this job is a waste of time. I used a diamond file set that came as a freebie from ArcEurotrade several years back to square out the holes. Might be worth making a guide bushing for drilling accurately. I didn't bother. Just set a pin sized to be a nice fit in the original bore vertical in the drill vice, dropped the gear over and had at it with a smart new drill. Clive.

|

| Ajohnw | 08/12/2016 17:29:09 |

| 3631 forum posts 160 photos | The design for the casting College Engineering sell works well. The centre height comes out correct for myford 7's. I use one on a Boxford but it needed packing up on a spacer. The fact that they match the centre height of the lathe is a good idea really. Some make things up to fit in a toolpost. The principle is the same on most of them really. A shaft that fits nicely in a hole on centre with the lathe and a lever arrangement that stops it rotating and provides the cutting force that is needed. Using the rack feed etc on the lathe to do it can be a very bad idea - something is likely to break. Can't find a photo of the one based on the casting as lots of people fabricate them. Few shots here Also some on youtube. John - |

| JasonB | 08/12/2016 17:52:39 |

25215 forum posts 3105 photos 1 articles | You can use a boring bar in the toolpost with a bit set sideways on and just plane it out using the carrage handwheel taking a thou at a time. Did these 3/16" wide ones that are 1" long in steel that way

Can even just do it with a HSS bit in the toolpost

|

| Ajohnw | 08/12/2016 18:27:40 |

| 3631 forum posts 160 photos |

Maybe this is one up for China and down for Myford and Raglan. John - |

| JasonB | 08/12/2016 18:32:48 |

25215 forum posts 3105 photos 1 articles | Think I did those steel ones on my Emco 8.6, the ali one is the Warco. I have broaches now so don't do it as much |

| Michael Cox 1 | 08/12/2016 18:50:34 |

| 555 forum posts 27 photos | I do not know the size of gear or slot you are talking about but I have used a very simple adjustable broach to make slots for pulley and gear. More details are here: http://mikesworkshop.weebly.com/small-hole-slotting-tool.html Mike

|

| Andrew Tinsley | 08/12/2016 21:49:05 |

| 1817 forum posts 2 photos | Thanks everyone for your help, Why is it that I can't think of even the simple answers like the drilled hole, bore and then use a swiss file on the half moon left? I fear that I don't have the muscles left to do a lot of filing! Simon, many thanks for your kind offer, I live in Rutland so I fear it would be a postal job! I would prefer to make up a slotting tool , because A/ it will expand my number of tools and B/ it will give me much needed experience as a retread. So it looks like a toss up between the Ian Bradley slotter and that from Mikes Workshop, oh and the College Engineering casting set. Which of the many Ian Bradley books is this described in? I have a few of them and maybe this is where I saw the design. Andrew |

| John Stevenson | 08/12/2016 22:06:23 |

5068 forum posts 3 photos | Andrew, I'm over on the Notts Derby border NG10 post code so not that far away if you want to pop over and I can broach they whilst you wait, only a 10 minute job.to do the lot. |

| Gray62 | 08/12/2016 22:07:38 |

| 1058 forum posts 16 photos | Just to throw another design into the mix is this keyway slotting tool from Hemingway Not cheap but if anything like other kits I have had from them, excellent quality with good drawings/instructions |

| Thor 🇳🇴 | 09/12/2016 06:02:04 |

1766 forum posts 46 photos | Andrew, I made a slotting attachment for my lathe some years ago and have used that to make keyways when needed. It bolts to the cross slide instead of the topslide. Thor |

| Hopper | 09/12/2016 08:03:04 |

7881 forum posts 397 photos | I cut a 5/32" keyway in a bored out 60T cast iron early Myford change gear using the same method as Jason, just hold a boring bar in the tool post with tool bit set "sideways" and rack it back and forth with the carriage handwheel. I did this on my old Drummond M Type when making the worm wheel for the GHT dividing head. It works, but is slow. I think if I were doing a full set of change wheels, I'd look at making one of the simple slotting attachments. Maybe one as suggested I think by LH Sparey that uses a long lever pivoted on the rear tool post, and attached to the main tool post, with the topslide leadscrew removed. But if you do one or two gears a day for a week or two, you will get there the slow way.

Edited By Hopper on 09/12/2016 08:05:05 |

| Ajohnw | 09/12/2016 09:25:18 |

| 3631 forum posts 160 photos | Maybe Neil will throw up a freebee. The design that uses the College Engineering Casting was in MEW Aug/Sept 1991. The casting doesn't look much different to the one I have which I thought was much earlier. The basic idea is that when the base has been machined the bore for the ram can be done by mounting the casting on the cross slide. That way it's exactly on centre and it's possible to slot keyways that will have a very sexy fit pretty easily. The problem with the hole and file idea is getting the hole on a true radial position. The keyway usually finishes up somewhat wider than needed, width depending on the skill of the person that does it.

John - |

| not done it yet | 09/12/2016 10:54:40 |

| 7517 forum posts 20 photos | Ajohnw,

You are right about the LJ Raglan. I would not use mine like that unless there was no other possible option, or the materials were relatively easy to cut. The 5" would be far more robust in this area and may well cope with care. Options suggested are not necessarily appliccable to all kit and the OP needs to take things into account, for his machine. |

| Clive Foster | 09/12/2016 11:15:38 |

| 3630 forum posts 128 photos | I wouldn't claim to be a filing expert but I had no trouble doing sufficiently good keyways in my change wheels for threading duties. Helps that the Smart & Brown uses a small key and relatively thin changewheels. Be different if taking real power or cutting large keyways. If I ever do a metric set for my Pratt & Whitney Model B I will be sorting out a bit of mechanical help. Even if you have a slotting head putting a drill in first makes the job a lot easier as the drill takes most of the metal out. If you don't have a slotting head and don't see enough work in future for making one to be worth the time and effort Jason's second picture is probably best approach to final finishing after opeing the drilled hole very close to size with a file. I'd probably have done mine that way if I'd had a suitable piece of tool steel in stock. Drilling first also reduces the load on a broach if you have a set. Clive. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in