The Great Silver Soldering Foul Up

| Andrew Johnston | 13/06/2015 22:25:03 |

7061 forum posts 719 photos | I was asked in another thread to amplify on my comment about a silver soldering foul up. So here goes! The jobs were for the gear change mechanism for my 4" scale traction engines, so largish (3/4" by 1/4" and 1-3/8" by 3/8" ) steel flats. I prepared all the parts, cleaned them in acetone and adjusted the fits to leave a gap of about 4 thou, as per the CupAlloys advice sheet. I was using Easy-Flo2 and an appropriate flux, both manufactured by Johnson Matthey. I mixed the flux with a little water and liberally applied it to the joints, before assembling the parts. So the flux was intimately applied to the joint area. I was using a Sievert burner and propane. After a gentle waft of heat to boil off the water in the flux I let the heat build up. As expected the flux dried out. It eventually went clear, like water. But when I applied the silver solder rod to the joint it didn't melt. So the joint isn't hot enough? More heat was applied until the joint was glowing dull red, and the silver solder did melt, but by this time the flux had disappeared and the solder didn't run properly. It is ironic that my previous silver soldering has been on brass, using oxy-acetylene, and I had no problems. Using the Sievert torch I seem to have all sorts of issues. I can think of some potential problems: 1. Both the silver solder and flux are old, 35 plus years 2. I'm not getting enough heat into the joint area to reach the required temperature before the flux is exhausted - this is my current working hypothesis. The assemblies are fairly large, up to 10" long. 3. Once up to temperature the gaps I had formed were rather bigger than 4 thou, so may be too large? 4. Some other foul up I haven't though of, or a defective operator. Even the part that I did manage to silver solder was covered in crud after it had cooled. Most of it came off with a soak in vinegar overnight. But it still comes nowhere near the standard of finish that I want. Hence the note in another thread about hogging them out of solid. Until that is the Bridgeport decided to call it a day. Some days you're better off staying in bed; I've had three days in a row like that. Roll on tomorrow! And now..... Andrew Edited By Andrew Johnston on 13/06/2015 22:25:42 |

| Bob Youldon | 13/06/2015 23:40:39 |

| 183 forum posts 20 photos | Good evening Andrew, It seems as if you have done most things nearly right but I'd comment as follows:- !, "The silver solder and flux are old", that 's not the problem, I'm old but I can still silver solder alright! 2 Heat, it could well be a lack of heat where it matters most, a job like the one you describe needs to be well surrounded with reflective refractory material to concentrate the heat on the job. 3, .004" is getting to be a fairly large gap but with the correct grade of silver brazing filler rod it shouldn't be too much of a problem. 4, Your flux gave up the ghost long before the job had attained the correct temperature, you will need a flux capable of prolonged heating and when conditions are right, warm the end of the filler rod, dip it in your normal flux and the silver solder will run easily. To clean off flux residues on steel fabrications, let the job cool right down and pop it into a bucket of clean water, leave it in there for a couple of hours, when you fish it out the residues will just wipe off leaving a nice grey finish to the steel. Both CUP alloys and JM metals web site are excellent for the selection of fillers and fluxes for particular jobs. Anyway, best of luck in your endeavors. Regards, Bob Youldon |

| Simon Collier | 14/06/2015 00:51:21 |

525 forum posts 65 photos | I find silver soldering steel much harder than copper and it's alloys. You must have a higher temperature flux. If you use Easyflow type flux you have no hope. HT-5 or similar is the go. You still have to get the job up to temperature smartly, and 4 thou is bigger than necessary and likely to cause trouble. I admit I hate it and get stressed every time. I would never attempt a steel assembly 10 inches long! |

| JasonB | 14/06/2015 07:37:51 |

25215 forum posts 3105 photos 1 articles | Age should not be a problem with the flux but type is, for things that will take a while to heat up you need Tenacity No 5 or HT5. Heat the biggest part so that gets not not the small parts first. You can also work your way along the part if it is big rather than trying to heat the hole thing feeding in solder as you follow the flowing flux rather than trying to get the whole lot hot. What size is your silvert burner? You want something with a decent BTU/Wattage and try to arrange some firebricks to contain and bounce back the heat. At the risk of being laughed at can you post a pgoto so we can see the proportions of the parts, or just the CAD images will do. J

Looks like you will have to console yourself playing with that box of tricks that hopefully arrioved Friday |

| Ajohnw | 14/06/2015 09:53:24 |

| 3631 forum posts 160 photos | Torch soldering / brazing etc can be a bit counter intuitive. What I think you will find you have done is put the torch too close to the work. The flame is more than hot enough to boil the flux off before the work has heated to the correct temperature. The answer is to move the torch back away from the work and heat things up more slowly. You could look around the web for flame temperatures but it would be better to find out for yourself on a couple of suitably sized pieces of metal. Find the distance that causes the flux to melt is a good starting point. You will probably then have to go closer once the work has reached that temperature to get the silver solder to melt but not so close that flux boils off. Done this way it will take longer to heat the work - that's the catch. People are inclined to heat it up as rapidly as possible and might even put the end of the blue cone on the work. I've more experience of gas air brazing but exactly the same factors can apply. John - |

| Clive Foster | 14/06/2015 10:25:27 |

| 3630 forum posts 128 photos | I was taught to keep the torch away from the flux when boiling off the water presumably to provide some pre-heat into the job. Not that a very young, spotty and hairy Clive had the nerve to ask why! With larger, couple of inches or more of joint, and steel jobs it was emphasised that much of the heating should be done close to the joint line rather than on it so the surrounding area would be pretty close to temperature before the final burst on the line ready for applying the silver solder with a decent dollop of flux on the end. This was using Easyflow which, as advised above, isn't really suitable for big jobs and long heating times. But it was what the firm supplied so ways had to be found. My mentor was quite happy to replenish near used up flux with neat Easyflow powder applied via the end of the silver solder stick if need be. Can work well but creates a fearful mess if it goes wrong. Definitely agree with John that slower heating is often the way with larger jobs. Clive. |

| Andrew Johnston | 14/06/2015 10:28:45 |

7061 forum posts 719 photos | I couldn't give a ****** if people laugh at me, I have the small set of vermiculite blocks sold by Cup Alloys for a hearth. The SIevert burner is 2941, about 7.7kW, as that is what came with my torch kit. Andrew PS: Yes the box of tricks did arrive on Friday. Fortunately I have discovered that among my broken carbide cutters are a number where the ends are chipped, rather than the cutter broken in half which is my normal trick. Edited By Andrew Johnston on 14/06/2015 10:31:11 |

| Michael Gilligan | 14/06/2015 10:54:21 |

23121 forum posts 1360 photos | Andrew, Looking at those shapes ... It may be worth trying the Silversmith's approach instead of the Engineer's ... i.e. make Pallions of strip, or form rings of thin wire Silver Solder, and include these in the joint space ... When the solder melts, it then flows outward through the joint, towards the heat source. Remember to position the parts such that gravity is your friend not your foe !! MichaelG. . P.S. ... Some helpful notes, here Edited By Michael Gilligan on 14/06/2015 11:00:23 |

| mechman48 | 14/06/2015 12:40:19 |

2947 forum posts 468 photos | Going by the sizes you state ( & pics ) you would be far better off stick / mig / tig welding those pieces, or if you can oxy/acetylene brazing; not saying it can't be done but you would be using a lot of gas & flux to get those items hot enough & mechanically strong enough for the use you want to put them too. Back in the day when I taught apprentices I used oxy/acetylene torch, cleaned areas with emery, flux paste applied, heat with a neutral flame till red hot, then dipped heated brazing rods into flux & applied to red hot area, dipping & applying rod as you pushed heat along joint with the rod flowing into joint ( steel plate, butt, lap, Tee, pipe to plate etc. )... just my 2 pence worth. George. |

| OuBallie | 14/06/2015 12:42:40 |

1181 forum posts 669 photos | Andrew, Thanks for starting a dedicated thread. Some good advise being offered, and no doubt more to come. I wouldn't dream of passing comment on your mishap. Happens to all of us in time, and Forums like this will come to ones rescue. Thank you Sir Tim! Geoff - Cleaning the stove, and removing all the cr@p from behind it. YUCK! |

| Ajohnw | 14/06/2015 13:01:46 |

| 3631 forum posts 160 photos | I have an interest in home casting of late and have been watching video's by Myfordboy - good source and an excellent design for a rolling machine. In one of them he silver solders - reminded me of brazing and lead burning at times, same sort of technique. Soft soldering with a torch needs the same technique. Thin metal isn't so bad as it will heat up quickly and hopefully before the flux has burnt off. John - |

| JasonB | 14/06/2015 13:24:44 |

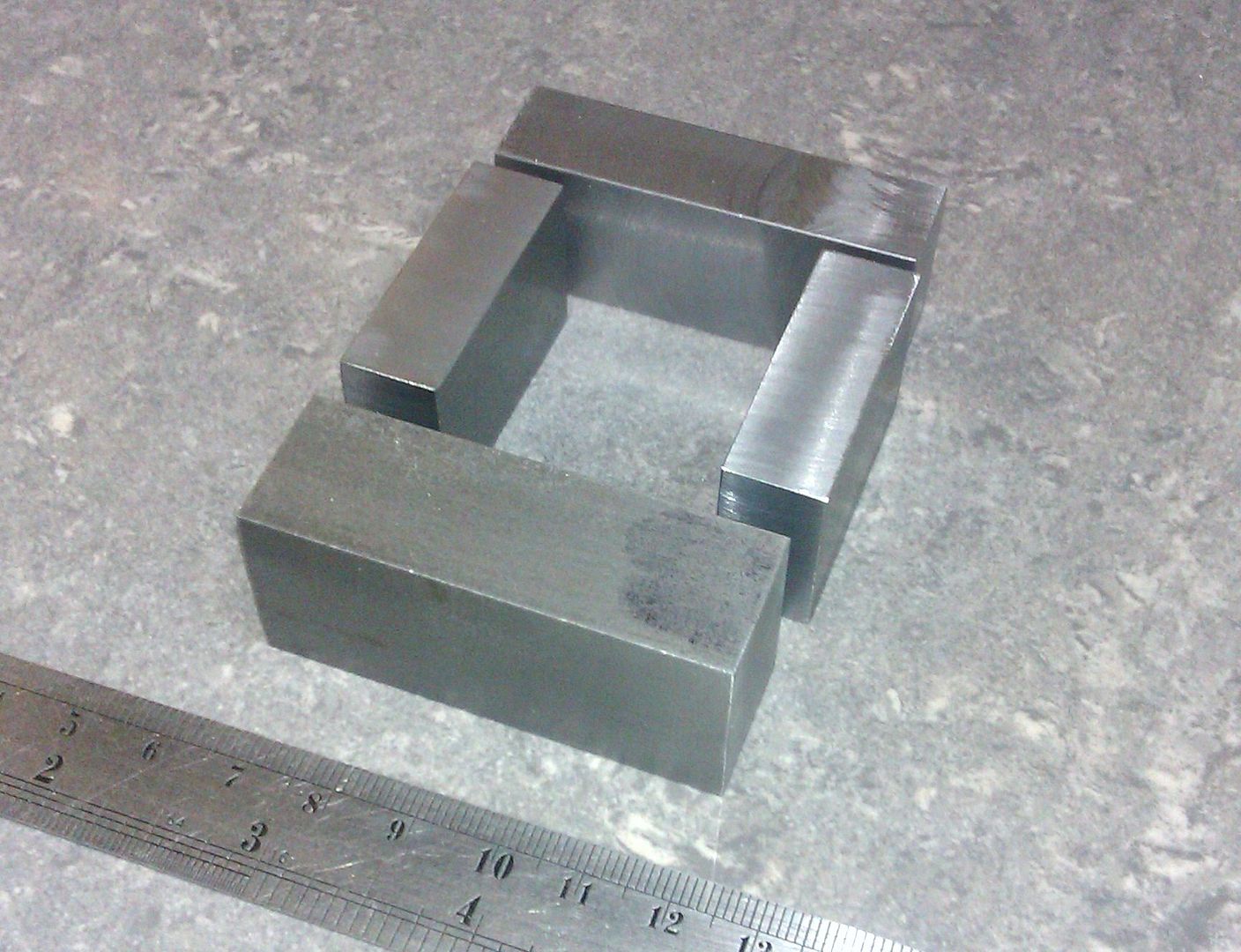

25215 forum posts 3105 photos 1 articles | Your torch should be upto it, mine is a bit smaller and will do large steel though it does take a while to get it upto temp. These bits are 1"x1" at teh bottom, 1x5/8 ate the sides and 1x3/4 at teh top and done with on a similar hearth.

As you can just see the solder has flowed through teh joint which was gapped with punch marks.

This is 3" dia and the two L shaped bits from 1.5"x0.75"

You didn't say what the flux is, I used Tenacity No5 for that. One other thought have you got the propane regulator turned up, you want 2 bar min 4 bar better. For your levers I would have fluxed it all up and started by working on the round boss at the end, once the solder had flowed on that I would move along to the bosses around the slots. Could be done as two separate heats but as the round boss will have put some heat into the bar you may as well use that and carry straight onto the second. |

| Neil Wyatt | 14/06/2015 16:27:13 |

19226 forum posts 749 photos 86 articles | I'll throw a cat among the pigeons for you. Try using borax as your flux You might be surprised. Neil |

| Ajohnw | 14/06/2015 16:35:31 |

| 3631 forum posts 160 photos | I wondered about that Neil, melts at around 750C and boils of at circa 1500 from the wiki. Sounds feasible but silver solder usually melts well below that and a gas air torch can put too much heat in so I wonder about the 1500. I'd guess it needs to be hotter than 750 to do it's job. John - |

| Ian S C | 15/06/2015 14:24:25 |

7468 forum posts 230 photos | I use borax, and for steel I'v got some thin brass sheet scrap, cut in strips, and that's what I use(mainly 'cause it's cheap,$0.00). Ian S C |

| duncan webster | 15/06/2015 17:51:21 |

| 5307 forum posts 83 photos | If you get the torch too close, it can deposit carbon (soot) onto the job, and silver solder will definitely not run. Been there done that! |

| Carl Wilson 4 | 15/06/2015 19:03:10 |

670 forum posts 53 photos | TIG weld it. |

| thaiguzzi | 21/06/2015 06:26:56 |

704 forum posts 131 photos | Stick welder... |

| Andrew Johnston | 21/06/2015 08:52:50 |

7061 forum posts 719 photos | I can't imagine that an arc welder would make a neat enough job; the parts aren't that large. I have an Esab water cooled AC/DC TIG welder, which also has a rather nice inverter driven arc facility, and also oxy-acelylene, so there are plenty of options. From the responses it should clearly be possible to silver solder these parts. I have bought some high temperature flux from Cup Alloys and will give it a try in due course. However, for these particular parts I've moved on and gone round the obstruction rather than tunnelling through it. The gear change lever has been hogged out of a lump of hot rolled. For the gear selectors I've changed the design so that I can screw, and loctite, the parts together. Andrew |

| Gary Wooding | 21/06/2015 11:51:28 |

| 1074 forum posts 290 photos | JOLT (Just One Little Thing), Tenacity #5 leaves a glass-like residue that is not soluble in water - it has to be chipped off. I don't know about HT5 'cos I've never used it. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in