Bench Drills

Clones "How many!!!"

| Jesse Hancock 1 | 28/01/2015 20:15:21 |

| 314 forum posts | Has anyone else noticed just how many bench drills are cloned? Badge engineering at it's best? |

| Rik Shaw | 28/01/2015 21:06:39 |

1494 forum posts 403 photos | Jesse - mine is an ALDI special and a good example of a cheap drill with massive play on the quill. I am on the lookout for something better - maybe a FOBCO or something similar. Rik |

| Jesse Hancock 1 | 28/01/2015 22:19:05 |

| 314 forum posts | I was shopping around today (net wise) to see if I could find a reasonable replacement for my Power Performance bench drill which has the same play as your Aldi special Rik. British second hand models carry prices which are just like buying a Myford as opposed to a Yingtong lathe. The idea was to keep the motor and anything that might be useful and use the pulley's to make a belt drive for the Mill. On looking about, the same drill which I have could be seen under many other trade names and paint jobs. The worst aspect, to me at least, was the variation in prices. Anything from £50 quid to £120.00 for the same item?! The one I have I think I gave about £25.00 some four years ago. I had one before this but it got stolen which I know I gave £15.00 for. So adding inflation I suppose £50.00 isn't too bad under the circumstances but £120!?! The other option buying pulleys also seems an expensive way to convert a machine since that's just the start of it. Finding suitable pulleys gave me a headache and I didn't earmark anything I thought would easily do the job. (Not enough information on the parts. See returning stuff from the internet.)) Perhaps the best thing to do is chew a couple of triple fall pulleys out of ally bar? Unless of course someone knows of a good supplier of pulleys? Jesse. Edited By Jesse Hancock 1 on 28/01/2015 22:20:22 |

| Nick_G | 28/01/2015 23:03:12 |

1808 forum posts 744 photos | . I have been considering one of these. **LINK** But at that price probably will be of a quality that causes disharmony to my desired tranquil existence.

Nick |

| Bikepete | 28/01/2015 23:54:22 |

| 250 forum posts 34 photos | "British second hand models carry prices which are just like buying a Myford as opposed to a Yingtong lathe." Depends how fussy and/or patient doing Ebay you are I guess - this search shows bargains are to be had under £100 with skill/luck, and that's just for the ones with the brand name in the title. Condition a lucky dip of course. Sorry if this is teaching granny etc. |

| Thor 🇳🇴 | 29/01/2015 05:03:39 |

1766 forum posts 46 photos | I got my Taiwanese bench drill many years ago and it is still delivering good work. Very little play in the quill. Hasn't been used that much the last years though, most of my drilling jobs are done with the mill/drill. Thor |

| Roger Provins 2 | 29/01/2015 07:25:40 |

| 344 forum posts | I'm always on the lookout on eBay for a decent old British bench drill but they're always so far away as to make collection uneconomic. Costs as much in fuel and time than the drill. One day maybe I'll find one but in the meantime my Ryobi variable speed EDP5530L does a reasonable job and is very convenient for drilling at the right speed. Roger |

| JasonB | 29/01/2015 07:56:31 |

25215 forum posts 3105 photos 1 articles | Same as Thor my Nu-Tool drill must be 30 years old and still works fine, think its Taiwanese but I now mostly drill on the mill since fitting the DRO. |

| Jesse Hancock 1 | 29/01/2015 08:23:47 |

| 314 forum posts | Thanks Bikepete but you'll see that most are collect and usually up around Yorkshire or in London areas. now If I make it out alive from the M25 wall of death I would deserve a medal in my humble opinion. Oh and yes did GooGoo every possible combo of ideas including local papers. Nike_G, Thor, JasonB, I'm in the same boat as Rodger Provins, after a days run and petrol , another day to get over the trip (not as young as I was once) I feel it's not worth it. I can't say this drill doesn't give good service it's that I want to use my new cross work table for spot drilling and so feel it has to be accurate. PS: My drilling is rubbish since now only one eye. PS: This editor needs retiringg IMHO see left. |

| andrew winks | 29/01/2015 08:28:46 |

117 forum posts 1 photos | I have a Chinese cheapie but only because I could not hold out for a tool room quality drill. They do the job, just and it's easy to use as a tapping/staking tool. I missed out on a Fobco at a sale many years ago, the bidding frenzy by those in the know resembled a group of girls front row at a Rolling Stones concert! Did finally have a win, picked up a old Waldown machine, made in Aust, solid and heavy with adjustable quill, in the process of converting the drive, was 3 phase. |

| Neil Wyatt | 29/01/2015 08:32:44 |

19226 forum posts 749 photos 86 articles | My Clarke one (that's one of the clones) is about sixteen and has had a lot of abuse. The quill is a little sloppy, but I am still able to drill PCBs with 0.7mm drills using it without breaking them. I did get through a pack of 10 1/32" drills making the rivet holes in my shunter, but I suspect I would have broken 9 of them even with the best drill in the world... All the movement is at the bottom of the housing quill. One day I will strip it., saw a cut 1/2" up from the bottom, split it and add a pinch bolt. One day... Neil |

| Jesse Hancock 1 | 29/01/2015 08:46:19 |

| 314 forum posts | Nick G the drill you are contemplating is one of those that I rejected since the main body of the drill is an exact copy of my cheapo £25.00 jobbie. Trouble is is how to check without the hassle of returns? RE: my earlier reply. Jesse. |

| Jesse Hancock 1 | 29/01/2015 08:59:48 |

| 314 forum posts | Neil I have just finished extending the height of my Power Performance cheappo. I can stand it on the floor and sit or leave it on the bench and stand to use it. G Clamp to secure. Tried modifying a cheap lever type drill stand to suite my Dremel but worst problem was the soft feel drill body. The accuracy also left a lot to be disired ie I have broken 10mm drills using the thing but it comes down at an angle as it flexes between base and post. Oh and the row the Dremel kicks up is enough to wake the gods. Jesse Edited By Jesse Hancock 1 on 29/01/2015 09:18:36 |

| _Paul_ | 29/01/2015 09:15:38 |

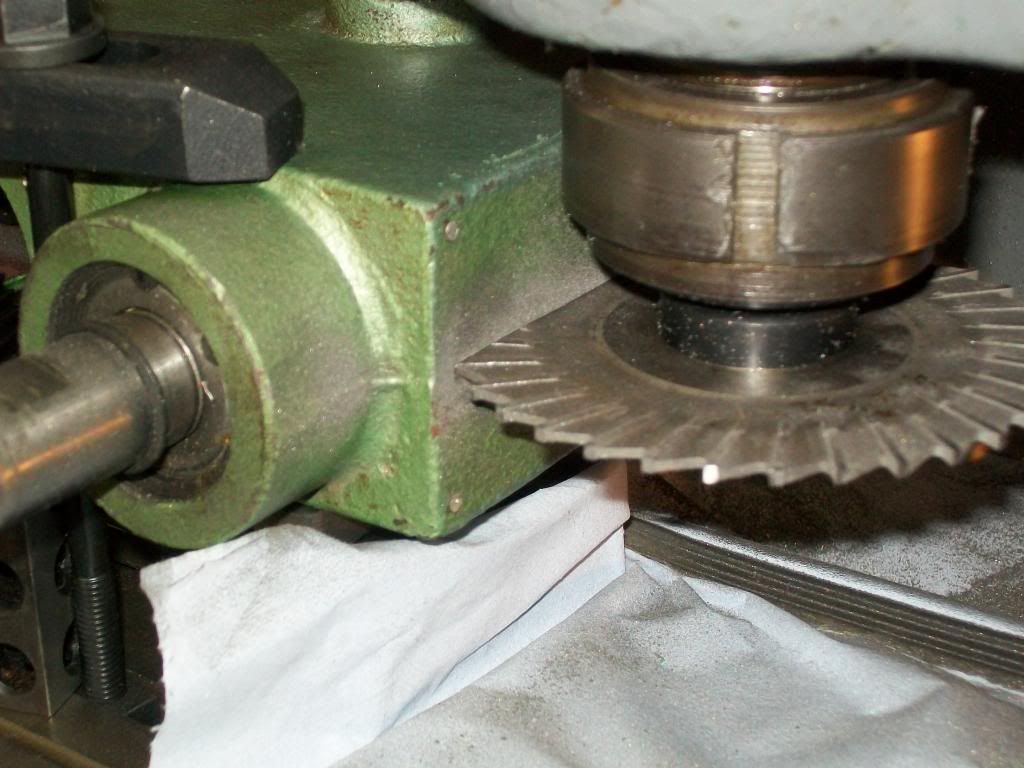

543 forum posts 31 photos | Some 20+ years ago I bought a "NuTool" 5 speed drill press....what a waste of money it must have had around 1/8" of play with the quill fully extended. I see that most of the ones you see in B&Q & Wickes etc. all these years later still use that same basic "NuTool" design (and very similar castings). I finally got around to doing something with the NuTool drill and put a slitting saw through the casting and fitted a pinch bolt which fixed the play but while cutting the slot in it I had a good chance to see how really poor quality the castings etc. were.

Once completed I gave it away to my old mate Jeff Harris who has used it for some years now. This site shows quite well whats involved Drill Press Mods Paul |

| Jesse Hancock 1 | 29/01/2015 09:31:12 |

| 314 forum posts | Hi Paul, Yes I saw that on my wanderings it's a good idea and Neil is also contemplating this mod. Me I might have a go but I'm already worrying about cost of cutters and an arbour to suite the mill. No wonder people end up just modifying their tools. Jesse. |

| Douglas Johnston | 29/01/2015 09:37:52 |

814 forum posts 36 photos | The Record Power stuff seems to be a better quality than the real cheap stuff, but how much better is open to question. I bought a Record Power bandsaw a couple of years ago and have been quite impressed with the quality. As has been said before, Chinese sourced machinery seems to be available in different qualities ,even if the basic design is the same, so it is probably unfair to think that the £40 drill is the same quality as the £120 one. Doug |

| Harry Wilkes | 29/01/2015 10:02:50 |

1613 forum posts 72 photos | Paul Had a look at your mod's via the link you provided interesting and informative Thanks H |

| OuBallie | 29/01/2015 10:31:13 |

1181 forum posts 669 photos | Paul, Climb milling I see. How did that go? That link has made me think, as I was going to modify one of those 'Canopy' type round LED lamps to fit to my Mitco. If anyone comes across a Mitco floor standing drilling machine, manufactured in Pietermaritzburg SA, snap it up, you won't regret it. Geoff - Not coughing myself stupid at last, only silly. Back to normal then |

| Jesse Hancock 1 | 29/01/2015 11:37:58 |

| 314 forum posts | Doug I take your point but how without the cost of returns, do I find out? Just found a neat trick with a couple of mirrors at 90 degrees may help with my mono vision. If I knew how to link I would. Guidance anyone? Edited By Jesse Hancock 1 on 29/01/2015 11:41:59 |

| Hopper | 29/01/2015 12:55:10 |

7881 forum posts 397 photos | Seems to be the standard way with Chinese machine tools. Air compressors and some lathes are much the same with different brand names. Apparently under their government controlled economy, the standard design is given to various companies to produce under their name. Small factories produce the standard parts, others slap them all together and put their name on them. What gets me is that you don't seem to be able to buy spare parts for any of them. "Cheaper to buy another compressor mate" is the standard refrain. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in