The Workshop Progress thread 2018

| Neil Wyatt | 06/02/2018 18:35:59 |

19226 forum posts 749 photos 86 articles | Thanks... I was searching through the Christchurch Times... Neil |

| Roderick Jenkins | 06/02/2018 19:18:14 |

2376 forum posts 800 photos | I have absolutely no idea how Christchurch got into my original post |

| Richard S2 | 06/02/2018 22:05:41 |

237 forum posts 135 photos | Still too cold in my Workshop to stay in there for long, but managed to finish the constituent parts and complete the Fire Grate on my Modded 1" Minnie- I have also completely dismantled the engine to a pile of bits for more work on various parts and prep for finishing....in the warmth and comfort of the Lounge !!!!!. |

| Neil Wyatt | 06/02/2018 22:26:34 |

19226 forum posts 749 photos 86 articles | Looks far too nice to build a fire on. |

| mechman48 | 07/02/2018 11:05:12 |

2947 forum posts 468 photos | Started, again, on the swing arms for my Vertical Cross, using another method of construction... no pic at the mo... |

| Brian H | 07/02/2018 18:07:13 |

2312 forum posts 112 photos | Yesterday was an almost windless day in North Derbyshire which meant that I could do some silver soldering in the open instead of risking burning down my workshop because of its low ceiling! The item was the cylinders and valve chest for my 1858 Burrell-Boydell. It now needs a pickle and machining to finish. Brian |

| Neil Wyatt | 07/02/2018 19:29:31 |

19226 forum posts 749 photos 86 articles | I like that Neil |

| JasonB | 10/02/2018 20:26:07 |

25215 forum posts 3105 photos 1 articles | Think I need to start a thread for negative progress

|

| jimmy b | 11/02/2018 09:17:38 |

857 forum posts 45 photos | Today I fell out with my ARC versatile milling vice!

Doing a job yesterday, it really tightened up trying to undo it. A load of crap had got into the threads and worked right into the nut. Its now demoted to No. 2 vice. Its a flawed design, in that respect. Some of the "Kurt" ones have wipers on the thread and shim in the gap for this very reason.

Just glad I cleaned it out rather than carry on and bugger the tread right up! (I've seen that done at work, cast iron dust got in there and seized a £600 vice!)

Jim |

| Brian H | 11/02/2018 10:17:19 |

2312 forum posts 112 photos | Posted by Neil Wyatt on 07/02/2018 19:29:31:

I like that Neil Thanks Neil, I'm now working on the mechanism to raise the crankshaft so that the pinions on the ends engage with the internal gears in the hind wheels. Will post again when there is more to see. Brian |

| mechman48 | 12/02/2018 14:38:09 |

2947 forum posts 468 photos | Small but progressing, remade ( 2nd time ) the swing arms for the Vert.cross engine...Just need to clean up ... |

| Mark Rand | 12/02/2018 22:16:50 |

| 1505 forum posts 56 photos | Posted by jimmy b on 11/02/2018 09:17:38:

Today I fell out with my ARC versatile milling vice!

Doing a job yesterday, it really tightened up trying to undo it. A load of crap had got into the threads and worked right into the nut. Its now demoted to No. 2 vice. Its a flawed design, in that respect. Some of the "Kurt" ones have wipers on the thread and shim in the gap for this very reason.

Just glad I cleaned it out rather than carry on and bugger the tread right up! (I've seen that done at work, cast iron dust got in there and seized a £600 vice!)

Jim

Is it worth getting a Kurt brush seal and retro-fitting it? You'd still be about £400 ahead on the deal compared with a 6" Kurt. Edited By Mark Rand on 12/02/2018 22:17:19 |

| mechman48 | 13/02/2018 00:45:20 |

2947 forum posts 468 photos | Finally ! completed the swing arms for my vert.cross engine... on the third attempt |

| Brian H | 18/02/2018 07:59:59 |

2312 forum posts 112 photos | I've spent the week remaking all the parts I made last week! (for my 1858 Burrell) This was due to a variety of problems such as using some engaving brass on a silver soldered job and the brass behaved like plasticene on subsequent operations, and I changed my mind about how to make a couple of items. Also made a couple of mistakes in marking out. oh well. On the up side I have discovered just how useful is the ER32 collet set is that was a Christmas present. I realised that I can use my mill/drill as a mill one minute and then use drills with only a change of collet needed. I'm so pleased with the set that I have ordered hex and square Stevenson blocks. Brian Edited By BDH on 18/02/2018 08:01:04 |

| Jim Nic | 18/02/2018 10:57:54 |

406 forum posts 235 photos | Swing arms look good George. Jim |

| mechman48 | 18/02/2018 11:09:51 |

2947 forum posts 468 photos | Posted by Jim Nic on 18/02/2018 10:57:54:

Swing arms look good George. Jim

|

| IanT | 18/02/2018 12:33:15 |

| 2147 forum posts 222 photos | Very nice work Brian - but sorry to hear about your 'plasticene' experience. I think you will find many good uses for the Stevensons ER blocks... IanT |

| Brian H | 18/02/2018 13:31:50 |

2312 forum posts 112 photos | Thanks Ian, I already have work lined up for the Stevenson ER Blocks, I need to mill squares on 2 shafts for handwheels and I have a couple of oilers that need hexagons milling in awkward places. I'm sure I will find lots of similar uses. Brian |

| Neil Wyatt | 18/02/2018 15:31:23 |

19226 forum posts 749 photos 86 articles | Posted by JasonB on 10/02/2018 20:26:07:

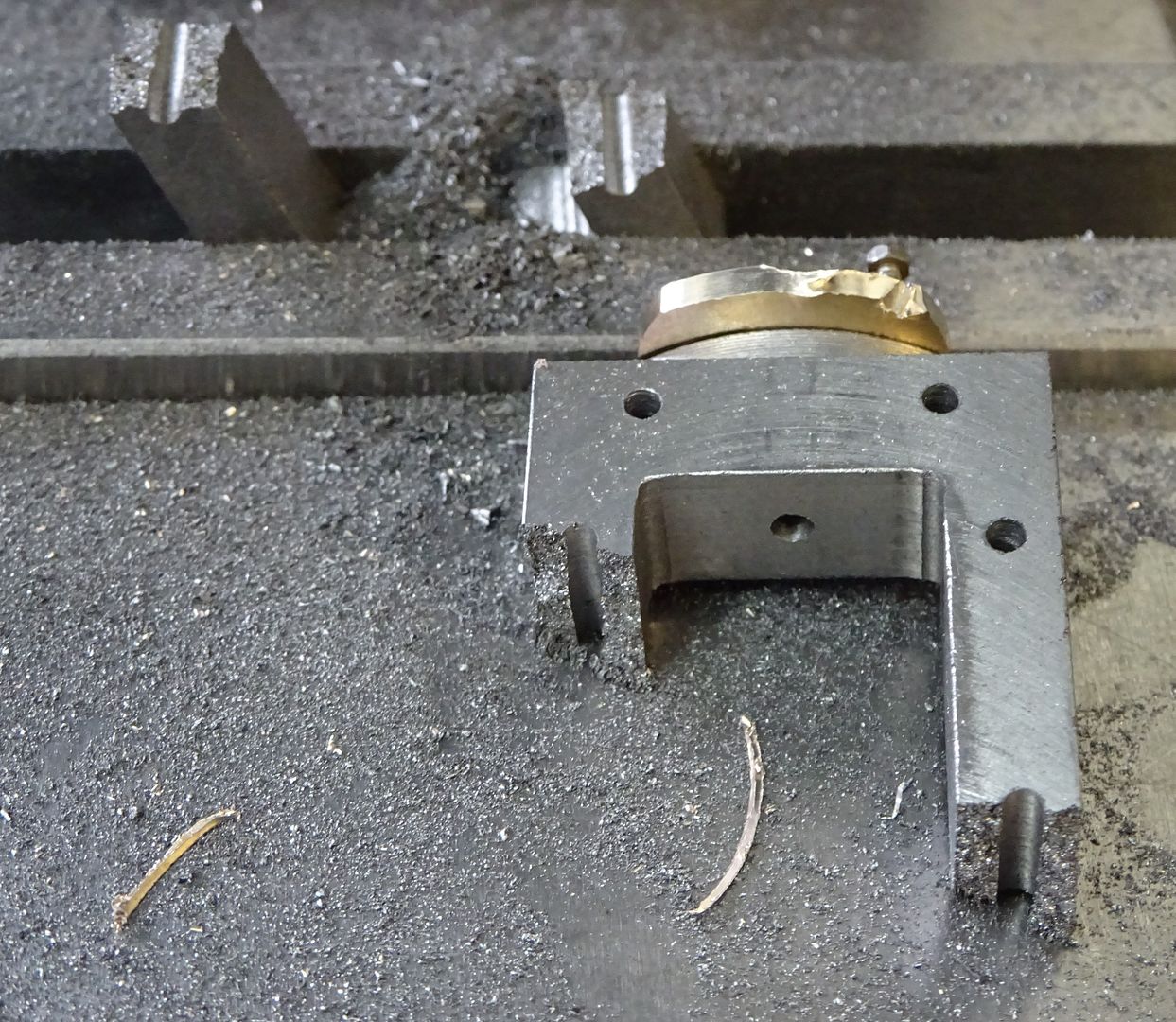

Ow. Crunchy cast iron with a chewy brass topping... Did the cutter survive? Neil |

| JasonB | 18/02/2018 17:22:42 |

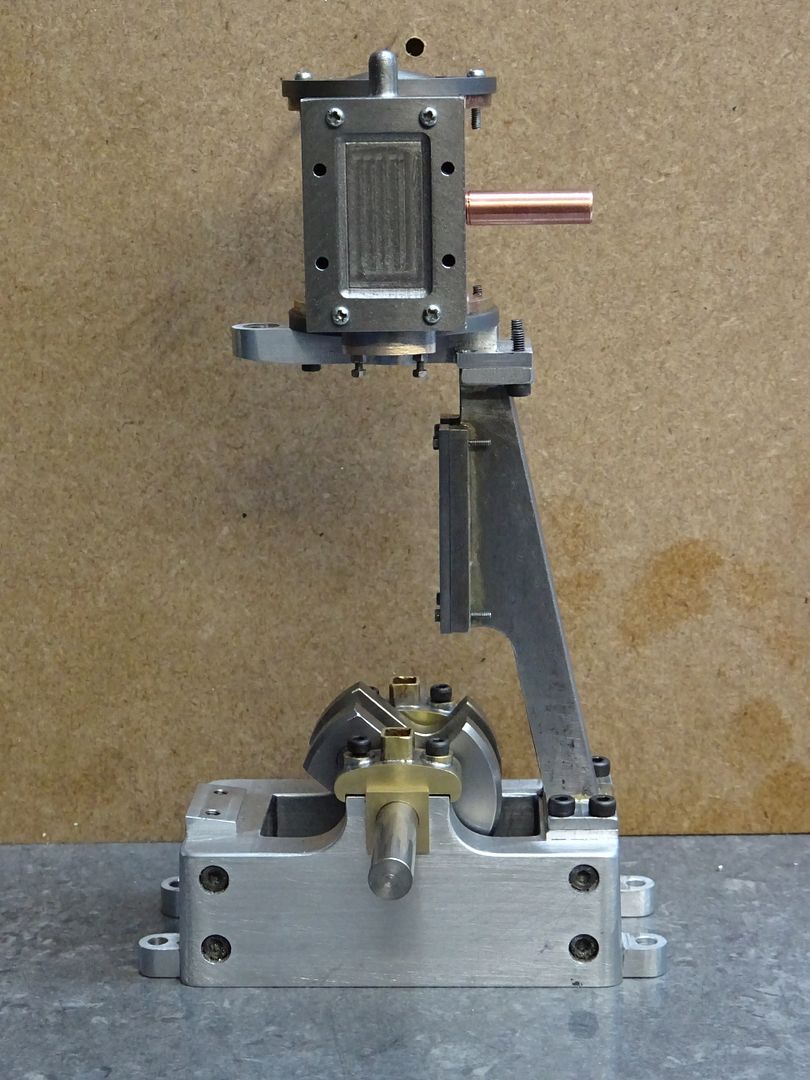

25215 forum posts 3105 photos 1 articles | Yes cutter was OK, a brazed tip one ground for external cutting with the boring head. It was a combination of a bit too much above the vice, reclaimed cast iron and using the quill feed rather than feeding the head down as I had done to shape the CI Got the cylinder and top & bottom covers done this week and a few other odd bits

|

This thread is closed.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in