The Workshop Progress Thread

Report your modelling and workshop milestones in this thread.

| JasonB | 24/10/2015 19:54:34 |

25215 forum posts 3105 photos 1 articles | Decided to saw down the middle of this bit of bronze about 1"x"x3" to see what was inside

With a bit more poking about I found an eccentric strap

Edited By JasonB on 24/10/2015 20:23:27 |

| Boiler Bri | 24/10/2015 20:31:04 |

856 forum posts 212 photos |

John Thorne, how did you go about the bores on your drain cocks please? I want to make some for my 4" Durham cylinder, the ones available commercially are too small.

Brian |

| Neil Wyatt | 25/10/2015 08:49:46 |

19226 forum posts 749 photos 86 articles | > With a bit more poking about I found an eccentric strap That's how Jason doies it - he get model versions of these:

|

| NJH | 25/10/2015 10:07:51 |

2314 forum posts 139 photos | No no no Neil Eccentric strap NOT Eccentric scrap ! N |

| JasonB | 25/10/2015 10:13:41 |

25215 forum posts 3105 photos 1 articles | Neil when you said you hoped to have a couple of bits ready by September that is not what I had in mind

I like that Norman |

| John Hinkley | 31/10/2015 14:20:30 |

1545 forum posts 484 photos | Never one to pass up the opportunity to flog a dead horse, I've just finished version 3 of my tool post spindle. I hope I have combined the best bits of the previous two designs and come up with the final article. More by accident than design, however, is the fact that I ordered the wrong size toothed belt for the combination of pulleys that I selected. This, however worked to my advantage as I was able to juggle the collection of pulleys in my stock and, by re-ordering a belt 15mm longer, was able to mix and match belts and pulleys to give various ratios with the same centre distance. The results of my labours are shown below: Front view with alternation pulley/belt combination. Rear view - ditto. With the exception of the largest/smallest pulley combo, swapping the pulleys from driven to driver, as well as combining with the crude electric speed control, an useful range of speeds can be obtained. The spindle mounts in the QCTP on the lathe either radially or axially. Following a brief period of navel-gazing, it occurred to me, that with suitable mountings, I could also use the unit as a basis for a tool grinder/sharpening device. A quick rummage for some boxes and the addition of a Harold Hall grinding rest resulted in this mock-up: Just when I thought I'd finished - another project looms! John |

| JasonB | 01/11/2015 16:16:21 |

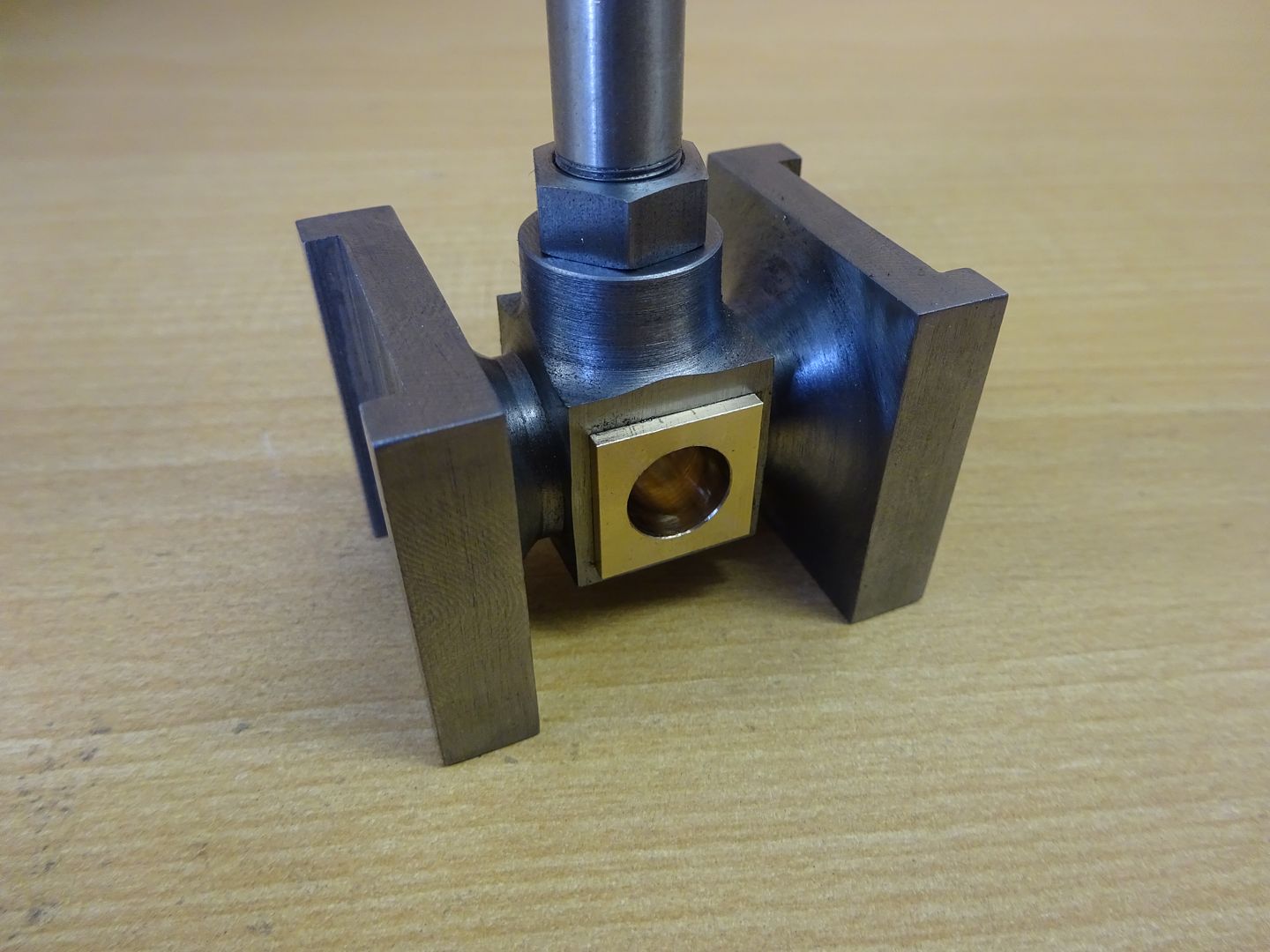

25215 forum posts 3105 photos 1 articles | Made the crosshead for the Tidman engine over the weekend from a block of CI, size is approx 1.375" sq x 1.875" long. Pressed in bronze bearing, 3/8" stainless piston rod and 1/2" hex locknut.

|

| John Thorne | 01/11/2015 16:38:17 |

19 forum posts 9 photos | John Thorne, how did you go about the bores on your drain cocks please? I want to make some for my 4" Durham cylinder, the ones available commercially are too small.

Brian Hi Brian Sorry it took so long to get back to you but did not see your post till today. The tapered bore was done with a small boring with the top slide set over and the cock plugs were turned at the same setting. I first drilled the bodies and used that as a guide to set them up in a 4 jaw chuck. The body shape was formed after so as to avoid jaw marks on the finished job. I can PM you the drawing if you require and you can scale it down John |

| mechman48 | 09/11/2015 18:41:18 |

2947 forum posts 468 photos | Plodding on with my small gyroscope build... have machined the flywheel & lightened the centre, having drilled the holes using DRO co-ords as the first attempt indicated an out of balance somewhere. For those interested I set up on the ally sub table I made last year, held in the vice... Simple enough from drawing but lets see if it works this time...? |

| John Thorne | 10/11/2015 21:02:26 |

19 forum posts 9 photos | Hi Some more parts made at home for a Westinghouse pump John |

| Ady1 | 11/11/2015 10:13:38 |

6137 forum posts 893 photos | Posted by Neil Wyatt on 25/10/2015 08:49:46:

> With a bit more poking about I found an eccentric strap That's how Jason doies it - he get model versions of these:

A rare find. The original tooling for an Adept super ! Edited By Ady1 on 11/11/2015 10:14:38 |

| JasonB | 15/11/2015 16:26:50 |

25215 forum posts 3105 photos 1 articles | Over the weekend I have converted a piece of 0.75" x 1.5" EN3B into a pile of swarf and been left with this which looks like a conrod

The strap was bent up from a bit of 4x15mm black bar, an offcut welded into the end to stop it closing up while in the vice so it could be final machined.

Still a bit more to do. |

| JasonB | 22/11/2015 13:17:52 |

25215 forum posts 3105 photos 1 articles | I got the big end bearing done yesterday as well as the cotter and wedge to hold it all together. This allowed me to finalise the size of a few bits like the piston rod length so could not resist making up a couple of plugs so that I could try the Tidman on a bit of air, fired up straight away with my eyeballed timing setting and the governor butterfly valve seems to control teh speed quite well on teh 15psi I'm running at, no gaskets, gland packing or piston rings fitted at the moment.

J PS don't jump when te compressor kicks in just after 60secs, organ music will have to wait until its all finished.

Edited By JasonB on 22/11/2015 13:22:13 |

| Neil Wyatt | 22/11/2015 20:01:16 |

19226 forum posts 749 photos 86 articles |

It's a good 'un. Neil |

| John Stevenson | 24/11/2015 19:15:33 |

5068 forum posts 3 photos | No pics as yet, hopefully tomorrow but been round reckoning up what quick change tool holders I have. Including some specials that have things like knurling tools built into the holder and some obsolete holders to hold defunct type parting blades then the total count is 49 holders between two lathes.

Problem is once Deb's Phantom Bantam is in use and that's three lathes, we could be struggling for tool holders so hunt around and come up with a lump of steel 2" x 6" and 29" long. That will do nicely and should make 32 new holders.

So couple of hours on the saw tomorrow and should have the blanks cut out. Pictures later. |

| I.M. OUTAHERE | 25/11/2015 05:08:22 |

| 1468 forum posts 3 photos | Posted by Ady1 on 11/11/2015 10:13:38:

Posted by Neil Wyatt on 25/10/2015 08:49:46:

> With a bit more poking about I found an eccentric strap That's how Jason doies it - he get model versions of these:

A rare find. The original tooling for an Adept super ! Edited By Ady1 on 11/11/2015 10:14:38 Must be for a late model Adept Super ! |

| Andrew Johnston | 25/11/2015 21:54:14 |

7061 forum posts 719 photos | This part is in the 'progress' thread because it represents progress, unlike the previous attempt. Here's the part with undamaged screw threads, 32tpi on the larger (1" ) diameter and 19tpi Whitworth (aka 3/8" BSP) on the smaller: Through the radial holes the inner valve seat can be seen, with undercut made using the homemade cutter previously shown. Two more to go! Andrew |

| Tractor man | 02/12/2015 21:46:46 |

| 426 forum posts 1 photos |

The new Shaftesbury jig borer/light milling machine arriving at home. Looks pretty nice at first glance but an obvious problem is how am I going to get it in the garden/workshop? Scratch of the head for two minutes then out came the spanners. Long story short, a lot of puffing and panting and she was home but in bits. I am midway through the stripping and cleaning and have decided to have the table surface ground to get rid of a few dings. I also bought a power hacksaw while I was at it and this will be next in the dry dock when the jig borer is complete. I managed to blag a lot of tooling from the supplier so many thanks to those who offered chucks etc on 30 Int tapers but I am now in possession of everything I need. Including a brand harry spankers INTEGI U.M.200 boring head which looks very good and probably a lot more expensive than I paid for it. Anyone have any experience od Integi stuff, its Spanish. More as things get cleaner. T

|

| John Stevenson | 02/12/2015 22:31:04 |

5068 forum posts 3 photos | Funnily enough this landed on my yard this morning.

Pretty complete, has the arbors, vise, collet chuck with collets and a full set, I think ? of 8 pick off feed gears.

No manual and there isn't one on the Yahoo Harrison group. The Anilam DRO is playing up and I suspect the head. No time to play with it at present so it's gone into winter storage. |

| Nick_G | 02/12/2015 22:52:11 |

1808 forum posts 744 photos | . Very nice bits of new kit you have there Tractor man and John. Nick |

This thread is closed.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in