Old lathe, chuck accuracy

| Ian S C | 31/01/2010 10:33:26 |

7468 forum posts 230 photos | Mark have you got a 4 jaw chuck? If so stick with that for now,its slower, but I'm not sure of availablity of collets. Did you get the bearings sorted? Ian S C |

| Mark Smith 3 | 31/01/2010 17:58:24 |

175 forum posts 36 photos | Sorry,Ian I wasn't refering to anything you said. Thankyou for the advice though.

Ian SC yes the bearings seem ok now. |

| Circlip | 31/01/2010 18:49:00 |

| 1723 forum posts | No agopolies required Mark, just trying to stop you falling into the three jaw trap that most starters do, as SC has said, if you havea four jaw stick with that one.

Regards Ian. |

| Mark Smith 3 | 01/02/2010 18:11:06 |

175 forum posts 36 photos | Thanks Ian, yes I have a four jaw, it is a monster. I am thinking of getting a small one but will have to make a back plate to suit my spindle. I also now have a DTI just need to buy or make a stand. But good news I have trued up a flywheel and for the first time no wobble. |

| AndyB | 01/02/2010 19:27:48 |

167 forum posts 7 photos | Hi all,

As another beginner I am reading all this with interest.

I have an older lathe, a Drummond B long bed with a1MT nose and tailstock, which I usefor everything.

I also have an M and a Roundbed which both have 2MT noses and tailstocks.

Learning all about everything as I go!

Can someone please explain about the differences between the ER collets? I have been looking at ER25 because they seem more compact in the pictures but reference has been made here to ER32.

Many thanks in advance

Andy |

| mgj | 01/02/2010 20:59:18 |

| 1017 forum posts 14 photos | The ER32s are bigger with a bigger range and more expensive. Same idea and design, just a bigger version. |

| Keith Long | 01/02/2010 21:20:12 |

| 883 forum posts 11 photos | Hi Andy How did you get a 2MT taper in a round bed spindle - looking at mine there isn't room - OK it would probably just fit but the nose would be left very thin. Have you changed the spindle for a bigger diameter? Keith |

| AndyB | 02/02/2010 18:34:08 |

167 forum posts 7 photos | Sorry Keith,

You are absolutely correct, the RB has a 1MT nose but a 2MT tailstock. Sorry, I haven't had the covers off for a while.

Meyrick,

Thank you very much for the help; 25's would probably be better to mount on a 1MT then.

Onward and upward... |

| Keith Long | 02/02/2010 22:28:23 |

| 883 forum posts 11 photos | Hi Andy No problem - I was just wondering if it was possible to go to a bigger mandrel on the roundbed - I'd quite like to do that if it was. The 1MT fitting can be a bit limiting. Keith |

| russell | 03/02/2010 00:26:56 |

| 142 forum posts | i'm also thinking of purchasing ER25 collets and a 1MT holder for my drummond B type.

However, using the MT holder means loss of the hollow spindle. Is it feasible to make/buy an ER holder which would screw onto the drummond spindle (like a chuck backplate? would that lose the accuracy of the collet system?

thanks

russell |

| Jim Whetren | 03/02/2010 00:40:55 |

| 50 forum posts 1 photos | Hello Russell,

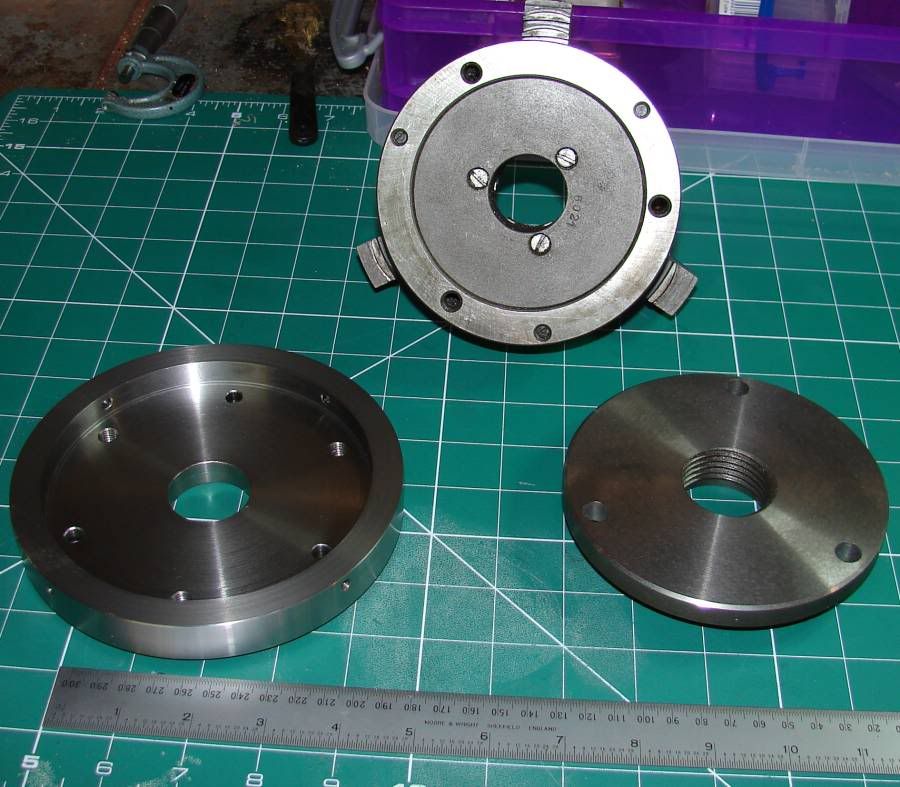

I have sucessfully made a chuck for ER 20 collets to use them on a Cowells lathe.

If ypu make the register a good fit when it is screwed onto the mandrel, then bore the taper for the collet in situ, it should hold true.

I must admit that on all the ER holders I have made, I cheated and used purchased closing nuts to avoid the turning of the eccentric locating flange. Go for it.

Jim |

| Stephen Benson | 09/03/2010 16:45:41 |

203 forum posts 69 photos | No one has mentioned fitting an adjustable back plate I have them on both my lathes a South-Bend and a Cowells you can set your three jaw to within 1/2 a thou with a DTI in about 30 seconds. |

| Chris Trice | 19/04/2010 00:34:04 |

1376 forum posts 10 photos | Both my chucks are fitted to backplates that have the shoulder turned a thou or two undersize. It took great care but I added long grubs screws to the rear edge of the chuck body at the north, south, east and west positions that bear on the shoulder of the backplate and the clearance allows a little bit of adjustment. It's like a cruder form of Griptru chuck. Tighten the bolts enough initially to hold the chuck in place against the backplate but not so firm that the grubscrews can't adjust the axial position. Once adjusted using a dial test indicator, you can then tighten the bolts to make the position secure. As a result I now have two Pratt Bernerd 4" chucks that hold consistently well across their entire gripping range with an accuracy around .0002" although I should emphasise the chucks are relatively new.

A point worth noting that although some chucks hold work inaccurately, they hold it consistently inaccurately so if, for example, you mark the piece of work with a small centre punch mark at the number 1 jaw position, providing you return the work to the chuck with the mark in the same position, it should run fairly true to its original position. However jaws that no longer hold the work tight at the front end can't be relied on and should be trued up by regrinding.

Having said all that, if you need real accuracy, forget the SC chuck. Use collets or the most unbeatable solution is to turn between centres. Edited By Chris Trice on 19/04/2010 00:38:17 |

| jomac | 17/05/2010 12:45:00 |

| 113 forum posts | Hi. I think that it was geometers articles published in ME some years ago that gave details on how to true up the chuck jaws (they can be found on this site and the internet), anyway I trued up my worn Bernerd chuck useing his method, which shows how to clamp the jaws. My chuck has three extra holes at the front which I drilled right through and spotted on to the back plate then drilled and tapped these, then locked a small piece of hardwood in the jaws 20mm diameter which is about the average size. Put threaded rod through the three holes and then clamped the jaws solid with three pieces of steel plate, you could use engineers clamps instead, that, kept the jaws in the right position, so that I could drill out the wooden block, then useing a cheap Dremel grinder SLOWLY rotated the chuck by hand, I used the largest grinding wheel I had, BUT the collet holder in these cheap grinders is rubbish it let go.!!!!! I never found the wheel again as it bounced around the workshop, Good workshop practice or what ????. I only took off the minimal of the most worn jaw but had to take off 5-6 thou off the others, the wear was mostly at the front. Now at 20mm diameter the DTI shows virtualy no run out, as previously mentioned old worn chucks give different readings at other sizes, you can get them refurbished but its cheaper to buy a new one. Swarf is good swearing at it is not. John Holloway

|

| John Coates | 09/10/2011 16:52:06 |

558 forum posts 28 photos | Sorry to resurrect this thread but I have been having some accuracy issues and searched for chuck accuracy and this thread came up

Is there an inherent inaccuracy with 3 jaw chucks? I only ask as I took my jaws out and cleaned out what I could see with a toothbrush and then put the jaws back in. As I did so I thought about the sequence and wondered whether the scroll acting on the third jaw was "behind" the position of the first jaw as that was fitted as the opening first passed its slot. So when the 3rd jaw is fitted the first (and second for that matter) jaw has already advanced closer to the centre of the chuck.

My inaccuracy was that after turning some bar and centre drilling, I turned the bar around and centre drilled, then I then drilled through and the resulting hole was off centre at the other end. I could see this as I turned it around and put it in the 3 jaw and the hole was noticeably "wobbly". Since then I've been trying to find out if it is the chuck, the mounting, or the setting of tailstock to headstock although I have lined them up using hard centres

Cheers

John |

| NJH | 09/10/2011 18:45:02 |

2314 forum posts 139 photos | Hi John My inaccuracy was that after turning some bar and centre drilling, I turned the bar around and centre drilled, then I then drilled through and the resulting hole was off centre at the other end. I'm afraid this is very much the name of the game with a 3-jaw. The solution is to get a Grip-Tru Chuck in which you grip your bar then adjust to run true ( quite easy to get within .0002"), When you take the bar out it will hold other work of that diameter true so you can reverse your bar in the chuck and your holes should line up. For different diameters you will need to re-adjust. So then, you may ask, why don't they supply Grip-Tru in the first place? Last time I looked a 4" Grip-tru will set you back in excess of £500 !! The principle of the thing is that the position of the chuck body is adjustable on the backplate by moving three "micro-adjusters" Now I do know that Hemmingway supply a kit for an adjustable chuck backplate - does anyone have any experience of these? Regards Norman Edited By NJH on 09/10/2011 18:47:40 Edited By NJH on 09/10/2011 18:48:31 |

| John Coates | 09/10/2011 18:56:58 |

558 forum posts 28 photos | Posted by NJH on 09/10/2011 18:45:02:

I'm afraid this is very much the name of the game with a 3-jaw.

Regards

Norman

I thought that was the case Norman but as a beginner I just wanted it confirming by somebody more experienced. My suspicions were raised after reading quite a few articles by Harold Hall where after turning in the 3 jaw, any swapping round and the workpiece was then transferred to the 4 jaw and clocked. In terms of clocking the 4 jaw, how accurate should I try to get. Turning and drilling the cylindrical parallels to HH's design I got the workpiece to be somewhere between 0.05 and 0.1mm. Still have two to finish so should I try to be more accurate?

It seems that once I've got to this kind of tolerance once I try another by even the slightest adjustment, the workpiece then goes off in 0.1 - 0.2mm territory. Is there some black art to loosening the jaw and then tightening the opposite jaw to try and reduce to the minimum introducing further error?

John |

| David Littlewood | 09/10/2011 19:35:34 |

| 533 forum posts | John,

One factor that seems to have been overlooked here is drill runout. Even with a bar held perfectly concentrically (and repeatably) - for example in a collet - there is every chance that the drill bit will deviate if the hole is of any significant length. The amount of this will depend on lots of factors: the accuracy of the lathe bearings, the accuracy of the drill chuck, the accuracy of the starting hole, the adequacy of clearance of swarf from the drill flutes, and (probably most of all) the accuracy with which the drill bit has been sharpened.

As to the latter, if it has been re-sharpened (especially by a novice) or is of less than top-tier quality, there is a chance that the lips will have unequal length. This virtually guaranees that the hole will deviate, and the deeper it is the more it will deviate. Even with top-grade equipment in the hands of an expert, to get a hole to stay concentric at a depth 10x drill diameter takes a lot of care.

The late, and renowned, George Thomas, in his book The Model Engineer's Workshop Manual, sets out a very good discussion of deep hole drilling, and the steps you need to take to do it well. I heartily recommend this book; even if you never make any of the tools he describes, there is a wealth of useful information in it.

David Edited By David Littlewood on 09/10/2011 19:36:23 |

| mick H | 09/10/2011 19:41:19 |

| 795 forum posts 34 photos |

John.....you mention that the inaccuracy arose when drilling a piece of bar although no dimensions of the bar or size of drill are given. I have found that when drilling bar from end to end that like as not the hole at the emergent end will not be centred due to drill deviation. If drilling bar to more than about an inch depth (or even less) the safest approach is to drill both ends so that the holes meet in the middle, so to speak. Or for even more accuracy, bore the hole.

If the chuck is "consistently" inaccurate the adjustable backplate as suggested a few posts back may well solve your problem for general purpose work. It worked for me.

Edit.........David Littlewood's post was not there when I started typing this one out......and his suggestions are far better than mine.

Edited By mick H on 09/10/2011 19:53:03 |

| Nicholas Farr | 09/10/2011 19:46:04 |

3988 forum posts 1799 photos | Hi John, I wouldn't call getting an item to run true in a four jaw a black art, it's just a matter of finding a technique that you can repeat. I find that when you get extremely close to running true and need just that little bit more, the best thing is to very slightly loosen off the opposite jaw, but then nip it up again gently before tightening the jaw up that you are trying to reduce the run out on. Then you just keep repeating until you are satisfied with the amount of run out you feel is acceptable.

Regards Nick. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in