Using Counterbores

| not done it yet | 22/07/2020 07:19:22 |

| 7517 forum posts 20 photos | While counter-bores are good, if of the required size needed, are they really needed if a DRO is fitted? Seems simple enough to sort out the counterbore with a suitably sized end mill immediately after drilling/tapping (if only a very few to do) or returning to DRO settings for the hole (if several are required). Much the same with countersinks as well? |

| Michael Gilligan | 22/07/2020 07:54:19 |

23121 forum posts 1360 photos | Posted by not done it yet on 22/07/2020 07:19:22:

. While counter-bores are good, if of the required size needed, are they really needed if a DRO is fitted? […] . That rather depends on the the job at hand “Horses for Courses” MichaelG. |

| Paul Lousick | 22/07/2020 08:21:28 |

| 2276 forum posts 801 photos | If you counterbore after drilling each hole and don't move trhe table, a DRO is not required. An end mill does not produce a flat surface, square to the axis of the hole but not normally a problem Paul.

Edited By Paul Lousick on 22/07/2020 08:30:02 |

| AdrianR | 22/07/2020 09:05:45 |

| 613 forum posts 39 photos | How embarrassing, having my counterbore quoted. Don't make one the same as mine, it has a numpty mistake, it runs backwards. What is worse I sharpened it three times trying to make it cut, before I realised my mistake. Once the reverse button is pressed it cuts a perfect counterbore, lot cheaper than buying a set too. Adrian |

| Cornish Jack | 22/07/2020 11:55:21 |

| 1228 forum posts 172 photos | Possibly OT but a repeat of a query I posted some time back without a real answer. The photo shows a pair of tools which appear to have a counterbore function but the construction seems at odds with normal counterbore - they appear to operate as 'pull' tools rather than 'push'. The shanks are 2MT without drawbars and the 'bottom end' has a hole but not suitable for centres. These features would seem to indicate that the cutters (only mountable to face the shank) cannot apply pressure for the cut. The cutters are special to type, quality material, and come in a range of sizes. Does anybody recognise what they are, please? rgds Bill |

| Jeff Dayman | 22/07/2020 12:00:18 |

| 2356 forum posts 47 photos | It's a reverse side spotface tool I think. We had a similar version for finishing some spotfaces from opposite side, on valve castings in a firm I worked at years ago. We did them from the opposite side because the cating was sitting on a datum for other ops, and we wanted the spotfaces to be sized relative to that datum also. Picking up the datum after breaking the first setup would have been difficult. |

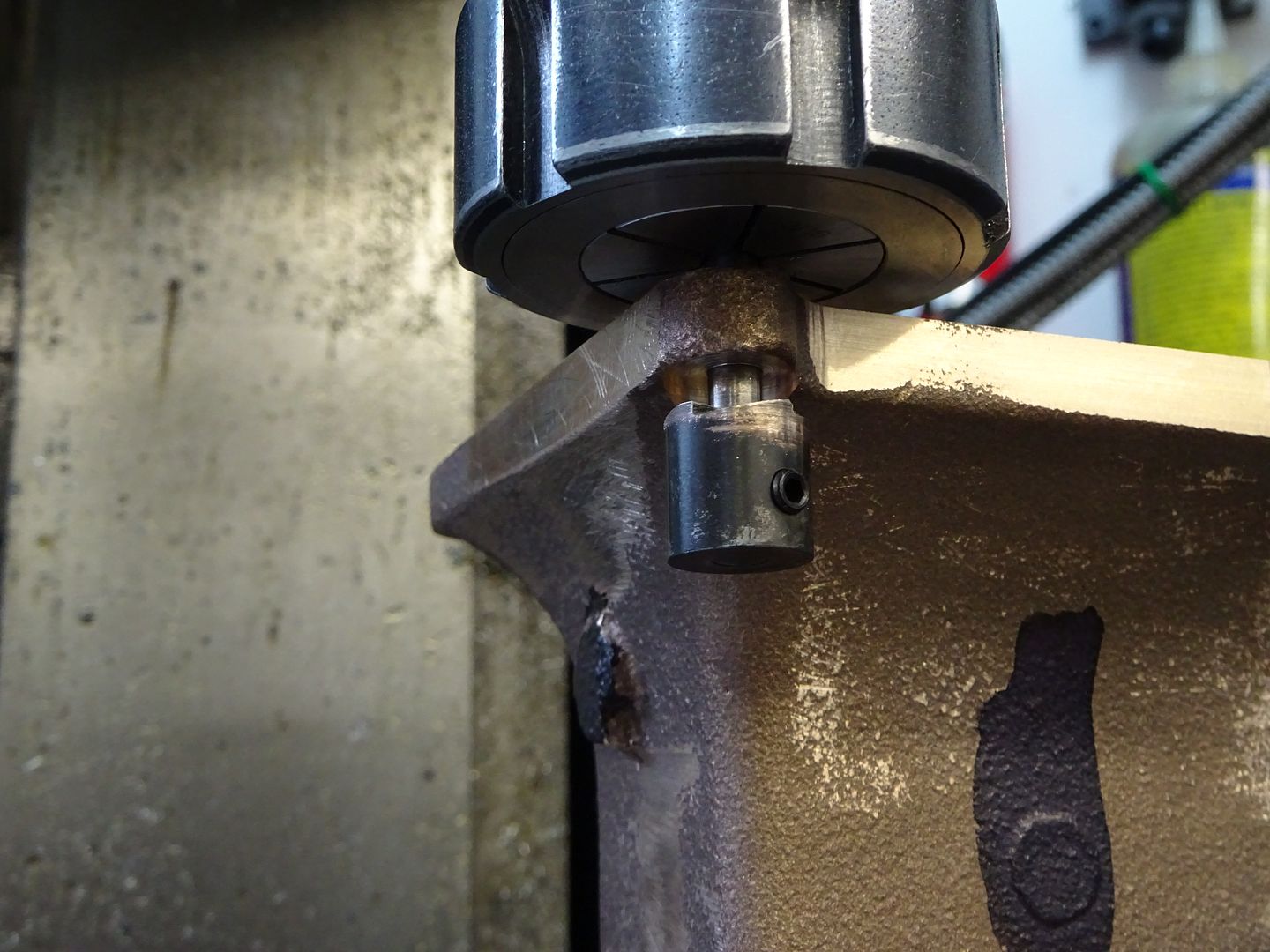

| JasonB | 22/07/2020 13:10:50 |

25215 forum posts 3105 photos 1 articles | Yes they look like reverse counterbores, one in action here which was positioned with teh DRO but could not have been done with an endmill

|

| Douglas Johnston | 22/07/2020 14:23:17 |

814 forum posts 36 photos | I had the same problem with a couple of my counterbores in that I did not have the correct size drill before using the counterbore. I simply solved the problem by holding the counterbore in an accurate collet chuck and used a sharp polished carbide cutter insert to reduce the diameter of the front part of the counterbore. Worked a treat on the hard HSS and left a mirror finish. It never fails to amaze me what you can do with this type of carbide insert. Doug |

| KW56 | 22/07/2020 15:07:02 |

| 8 forum posts | Counterbores for bolt and screw heads can be made with a suitably sized drill and then another drill of the same size ground to produce a flat bottom in the hole. Grind the end flat then back off on the bottom edges to create the cutting edges. Keep the back off angle as small as possible to help prevent chatter. For most work ( ie. gear covers etc. ) the standard drilled hole is perfectly good enough. |

| Cornish Jack | 23/07/2020 14:02:22 |

| 1228 forum posts 172 photos | Thank you for the replies. I quite see that they would appear to be reverse counterbores, but how do they operate without a drawbar fitting or provision for a centre to apply pressure ? Additionally, there is no adjustment for length. The design appears to be specific to one particular operation but what it was, I have no idea! rgds Bill |

| Mike Poole | 23/07/2020 15:32:59 |

3676 forum posts 82 photos |

if you have the facilities to grind this the you can make a counterbore to suit you own preference of pilot and counterbore size, many of our toolmakers used these as the commercial items were not preferred. Mike Edited By Mike Poole on 23/07/2020 15:33:50 |

| Tony Pratt 1 | 23/07/2020 15:51:36 |

| 2319 forum posts 13 photos | if you have the facilities to grind this the you can make a counterbore to suit you own preference of pilot and counterbore size, many of our toolmakers used these as the commercial items were not preferred. Mike Edited By Mike Poole on 23/07/2020 15:33:50 Made loads of those 'back in the day' when I was a Toolmaker & still have them some where, as you said the commercial ones were 'non preferred' Tony |

| Vic | 23/07/2020 16:42:14 |

| 3453 forum posts 23 photos | I often work with aluminium alloy so making your own from Silver steel is not difficult. I never seem to have the size I need though. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in