Boring large diameter hole in aluminium bar

| Hillclimber | 04/09/2017 07:56:53 |

215 forum posts 51 photos | I have a short piece of 4" diameter 6082 aluminium in which I need to bore a concentric 2" diameter hole to a depth of about 2" in my S7. Question in how best to do this? A boring bit sounds awfully long and slow, and I am unsure how best to manage that as a procedure? Should I stick it on the vertical slide and try a mandrel mounted boring head? Cheers, Colin Edited By Hillclimber on 04/09/2017 07:59:52 |

| Brian Oldford | 04/09/2017 08:03:42 |

686 forum posts 18 photos | How long is it? |

| Marcus Bowman | 04/09/2017 08:11:21 |

| 196 forum posts 2 photos | I have recently done much the same thing, for several workpieces. In aluminium, machining speeds are so high this is not a terribly lengthy job using large drills then a boring bar, compared to the same thing (also recently undertaken) in steel. I mounted my AL in the chuck, drilled to 19mm, then used a toolpost-mounted boring bar and power carriage feed. I used a tipped tool with an insert designed for AL (mirror polished, and with an aggressive rake). You have little chance without that, as an HSS tool will clog in seconds, especially at higher speeds without a lubricant. Using the insert, I machined the work dry, although flood coolant would be better. Coolant will also help prevent HSS tools clogging, but not for long. I also changed the speeds as the diameter of the bore increased, to stay within the efficient cutting speed range. The grade of AL also makes a huge difference. I used 6082 (HE30). 7000 grades are even better, but much more expensive.

|

| Ady1 | 04/09/2017 08:11:22 |

6137 forum posts 893 photos | Put it on the 4 jaw. Drill it as big as possible Open out with a boring tool so you can get a toolbit in Bore with a decent hss tool via the backgear to reduce heat issues. Finish off at higher speed

Alternatively, drill a hole in it it, then surface cut it (face cut) to depth with a hss tool |

| JasonB | 04/09/2017 08:20:37 |

25215 forum posts 3105 photos 1 articles | Get an isert bar with a CCGT type tip designed for aluminium and it will fly through it. Did much the same a couple of weeks ago, biggest issue is the swarf which can come off a bit long and stringy. |

| Mick B1 | 04/09/2017 09:01:21 |

| 2444 forum posts 139 photos | An HSS boring bit will work fine if you get the rake right, keep it sharp, and polish the top and tip radius with a slipstone to stop it picking up. |

| duncan webster | 04/09/2017 11:49:52 |

| 5307 forum posts 83 photos | If swarf sticks to tool give it a squirt with WD40. HSS plenty good enough in a S7 |

| Hillclimber | 04/09/2017 16:30:49 |

215 forum posts 51 photos | Posted by Brian Oldford on 04/09/2017 08:03:42:

How long is it? The piece I am working with is 2" in length. The finished length (as I have some other procedures to perform) will be 1.25". Finished article should look like the piccie, but smaller diameter. |

| Hillclimber | 04/09/2017 16:37:23 |

215 forum posts 51 photos | Posted by JasonB on 04/09/2017 08:20:37:

Get an isert bar with a CCGT type tip designed for aluminium and it will fly through it. Did much the same a couple of weeks ago, biggest issue is the swarf which can come off a bit long and stringy. Jason, something like this? http://tinyurl.com/y7wul957 Attractive idea, but I have just taken a look at recommended cutting speeds with this combo, and I'm seeing 2800 fpm? So a modest 5000rpm at 2" on my S7? Edited By Hillclimber on 04/09/2017 16:52:47 |

| JasonB | 04/09/2017 16:58:47 |

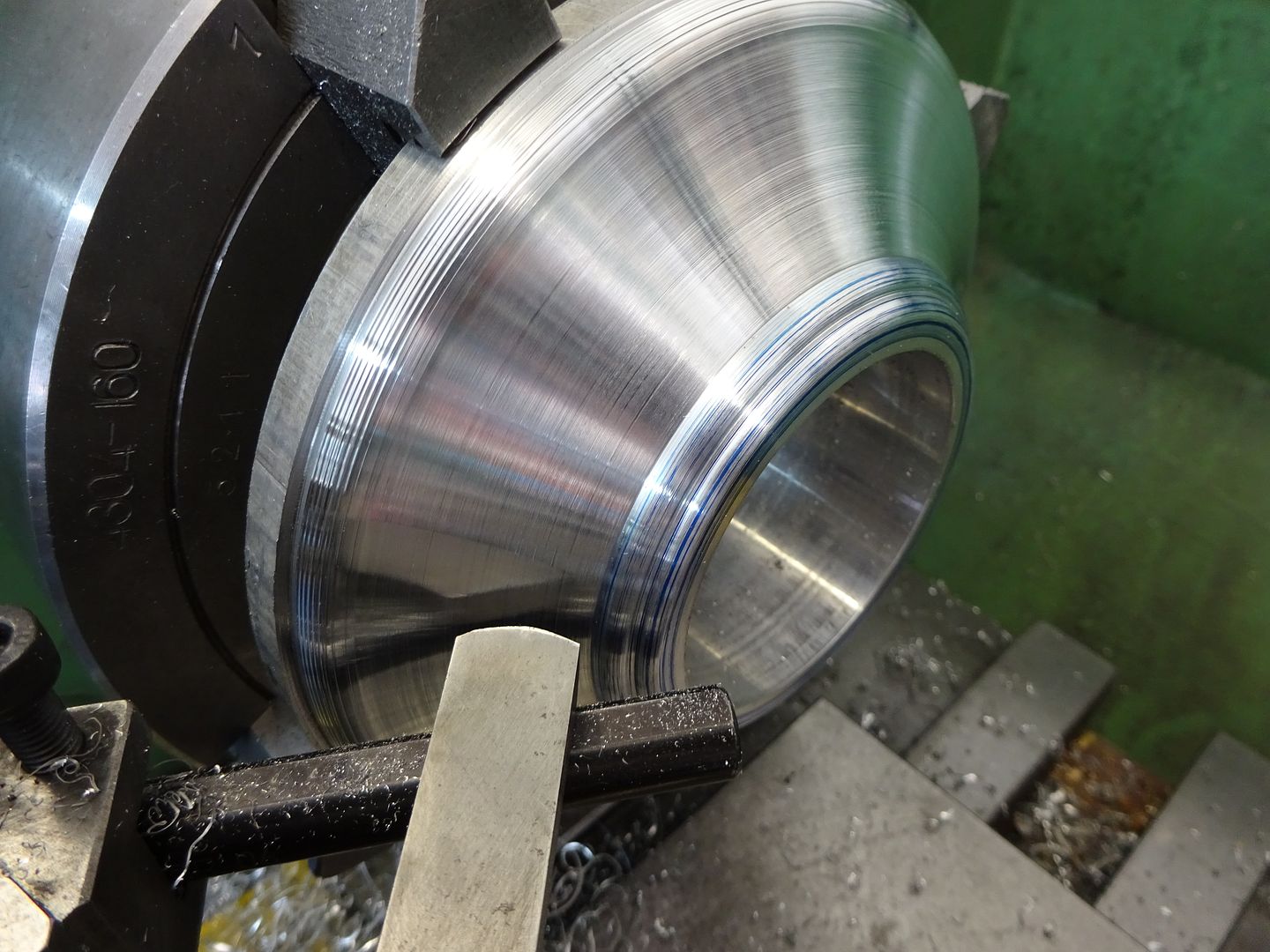

25215 forum posts 3105 photos 1 articles | I have exactly the same bar in my collection works fine at lower speeds, my WM 280 hardly ever runs in the high range so that means I'm below 950 rpm. Something like 500rpm will be fine as you get towards the 2" dia, bit faster as you start to open up the drilled hole. This is a 2.125" hole in a bit of 5" bar that I mentioned earlier no need for production speeds.

|

| Neil Wyatt | 04/09/2017 17:03:47 |

19226 forum posts 749 photos 86 articles | I bored a 2 1/2" diameter by 1" deep hole in the cast iron body of my rotary table. I survived...

Neil |

| Hillclimber | 04/09/2017 17:04:54 |

215 forum posts 51 photos | Jason, looks like a perfectly good job to me! Is that a four-jaw you're holding it in? |

| JasonB | 04/09/2017 17:13:49 |

25215 forum posts 3105 photos 1 articles | Yes, 6" 4- jaw as there would not have been much scroll engagement if I had used my 5" 3-jaw. The same tips will work well on the external surfaces. If you don't have other holders then the facing can be done with that boring bar by cutting from the middle out once a hole has been put in the middle. As others have said a bit of WD40 or paraffin will help a lot as it stops metal sticking to the tip. This is the outsid eof teh same part co-ordinate turned to profiel using a similar CCGT tip

|

| John Reese | 05/09/2017 00:57:55 |

1071 forum posts | Posted by Hillclimber on 04/09/2017 16:37:23:

Posted by JasonB on 04/09/2017 08:20:37:

Get an isert bar with a CCGT type tip designed for aluminium and it will fly through it. Did much the same a couple of weeks ago, biggest issue is the swarf which can come off a bit long and stringy. Jason, something like this? http://tinyurl.com/y7wul957 Attractive idea, but I have just taken a look at recommended cutting speeds with this combo, and I'm seeing 2800 fpm? So a modest 5000rpm at 2" on my S7? Edited By Hillclimber on 04/09/2017 16:52:47 The performance of a properly polished insert will be satisfactory at much lower surface speeds. Your insert should last a lot longer as well. 2800 fpm is likely based on acceptable tool life (heat related) in an industrial application. |

| not done it yet | 05/09/2017 04:32:36 |

| 7517 forum posts 20 photos | I have just taken a look at recommended cutting speeds with this combo, and I'm seeing 2800 fpm? So a modest 5000rpm at 2" on my S7?

Not sure where you got 2800 from - maybe an order out? I very much doubt you have a chuck that would run safely at 5000rpm! Let alone a lathe that could achieve that speed.

|

| John Olsen | 05/09/2017 05:43:46 |

| 1294 forum posts 108 photos 1 articles | Since the hole is to go right through, why not start it with a hole saw? They will usually go to about two inches depth and will leave you with a potentially useful slug of metal from the inside, instead of a skip full of swarf.. You can actually go in from both ends if necessary, giving the possibility of a hole up to nearly four inches long. You do need to back them out a lot, as there is no real path for the cuttings to get out so they will load up the teeth. I have done this in cast iron as well as in aluminium. It may not be any faster than just drilling and then boring, but I hate to waste good material. Choose a hole saw that leaves just a small amount to take out with the boring tool to clean up. John |

| Marcus Bowman | 05/09/2017 08:07:34 |

| 196 forum posts 2 photos | RPM = cutting speed (metres/min) / circumference (metres) Aluminium has by far the highest recommended cutting speed of all the common materials in our workshops, at 75 to 105 metres/min for HSS tools and 900 to 2200 metres/min with an uncoated polished insert. At the lower end, on a 50mm diameter bore, that translates to 500 - 668rpm for HSS and 5732 - 14102rpm for a tipped tool. Two limiting factors have already been mentioned: lathe top speed and chuck rating. So; run the lathe at top speed, but expect the carriage feed rate to be slow. The tipped tool rpm are well outside the Myford/Boxford/mini-lathe speeds, but that will not prevent the tips working reasonably well. I certainly would not be inclined to attempt this job with HSS tools, but opinions (and results) vary. I machine aluminium frequently on the lathe and the mill and have found the tipped tools or polished carbide cutters ground with cutting angles specifically designed for aluminium to be the answer to the clogging and sticking problem. Flood coolant helps too, of course, if you can stand the mess. WD40 stinks too much for me. Carnauba wax works too, but is too laborious to apply, and too expensive. Neat cutting oil works, as does water-soluble cutting oil. Application by toothbrush is too much effort, on a time-consuming job like this. Some manual lathes (Hardinge, for example) can run at 5000rpm, and suitably rated chucks are available at a price. The smaller diameter stages of drilling and initial boring will work best at correspondingly higher rpm. In the end, we do what we can with what we have, and a 50mm hole is perfectly achievable without too much difficulty (except, as previously noted, for the copious swarf). Despite the higher recommended speeds, I would simply use top speed and be content with the chrome-like finish on the final finishing cuts. Wondrous to behold. Two other points: The work needs to be gripped in such a way that there is clearance behind the work for the cutter to pass through without hitting chuck or faceplate, at maximum cut diameter. The boring bar for the final stages needs to be stiff and/or of large diameter, to prevent 'ringing', and to provide sufficient rigidity for the finishing cuts. It depends on the finish you need on the job. Marcus

|

| Hillclimber | 05/09/2017 12:04:00 |

215 forum posts 51 photos | Marcus, thanks for that addition. Not quite sure how to handle lubrication yet, but you very much confirm where I was getting to - just run the lathe as fact as I can. And, yes, talk of 5,000 RPM on my S7 was intended as ironic (ferric?). Figure I'll buy a couple of boring bars from someone like Arc (8 and 12mm) and just tuck in. I think the idea of using a holesaw is good, but will keep that one for harder materials. Really appreciate all the help. Many thanks to all. Cheers, Colin |

| Marcus Bowman | 05/09/2017 19:05:20 |

| 196 forum posts 2 photos | Although 8 and 12mm bars are useful, I made an additional larger diameter bar with an HSS tip for finishing cuts on larger bores. It's 25mm diameter and much more rigid than the smaller bars. Although the tip is an inserted bar of HSS, it is fine for 2 or 3 fine finishing passes (all of the same depth of cut). It is a bit of a chore having to remove the 4-way toolpost and mount the big bar, but I have found it pays dividends. One of these days, I will make a similar bar which takes a polished tip insert. As you probably know, those polished inserts are available with different tip radii, and the slightly larger radii are ideal for smooth finishing cuts. I have bought nice inserts and bars, and other tooling, from www.shop-apt.co.uk (with whom I have no connection). Marcus |

| Jon | 06/09/2017 00:45:18 |

| 1001 forum posts 49 photos | No need for the extravagance of a tipped boring bar that most likely wont be that good. Biggest drill you have straight through then merely open it up 1 to 3mm cuts feeling for whats happening.

If your worried about ripping it out heres another action shot 1000rpm on 5 1/4" dia 6082 x 1" long, 5 1/4" Bison 3 jaw chuck and powered cross facing off 1/2". ML7 will have to check clearance over cross slide or set tool appropriately.

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in