DRO usage

Info requested

| steamdave | 20/05/2016 23:09:08 |

| 526 forum posts 45 photos | I have had a 3 axis Sino DRO (purchased from Machine DRO) fitted to my milling machine for several years, but I'm ashamed to say that I have never got to use it for more than eliminating the effects of backlash to accurately position the table and the occasional switch between my preferred Imperial measurements and Metric. Being just a simple sailor (retired), I have been unable to understand the manual that came with the system, this being the main reason for not progressing further. Looking at the many buttons on the display, it must be capable of many functions, but not knowing what it is capable of doing, I don't really know what questions to ask about how to get the most - or at least more - out of the system. So, what common functions do others use their DROs for? Once I can find that out, then I will have proper questions which will involve asking which buttons to press in order to get the required result. Dave

|

| Andy Holdaway | 20/05/2016 23:22:42 |

167 forum posts 15 photos | Dave, I can't help you with your milling machine application, but I also have a Sino DRO fitted to my lathe, and while I find the functions I need are fairly intuitive, I can't for the life of me get the 'Tool store' functions to work correctly, so at the risk of hijacking your thread as soon as you've started it, if anyone is familiar with this function, please explain how it works as it would be quite useful! I would also agree that the manual is pretty awful, but I did find one on the internet for a similar DRO that had been re-written in native English, but I still can't get the Tool function working. If I can find the link I'll post it. Andy |

| Andrew Johnston | 20/05/2016 23:29:34 |

7061 forum posts 719 photos | My gut feel is that some 'features' may be a triumph of style over substance. I have a 2-axis industrial DRO (Newall) on my vertical mill. It only has a few features. I use it primarily for moving to specified X-Y co-ordinates. Almost everything I design is dimensioned from two reference edges, so if I set the axes at zero there then everything else follows. I use the absolute/incremental modes to either set two references, or to work on a local hole pattern or similar. I use the bolt pattern function for.....bolt patterns! But I also use it to rough out holes before boring to final size. A few strokes with a calculator gives a drill pattern where each drilled hole overlaps by a few thou, so the waste material drops out. My DRO also has a ½ function. If you zero the axis at one side of the work and then touch the other side pressing the ½ button gives a number which, when zero'd, is exactly half way across the work. Apart from inch/mm conversion that's it. I can't offhand think of any features that I miss. Andrew |

| Muzzer | 21/05/2016 00:56:08 |

2904 forum posts 448 photos | As Andrew says, there are a few standard functions that seem to be de rigeur for any self-respecting DRO but have very little practical purpose. You can see the bolt circle function and the "curve cutting" function in the last 2 photos of this photo album. The penultimate one is a sort of "manual CNC function" but is such a pain to set up and use that you'd be far quicker setting up a rotary table. By far the most useful function of the DRO (unless you drill lots of grids or circular patterns) has to be the "1/2" function Andrew mentions. When you use this function with an edge finder, it makes finding the centres of holes, slots, rotary tables, vises etc and the edges and corners of workpieces a doddle. You touch one edge, zero the scale, move to the second edge, press "1/2" and bingo, the scale becomes zeroed to the mid point. For edges, you touch off on the edge, zero the scale, lift the quill, move the distance corresponding to the radius of your edge finder (2mm?), zero the scale and your quill is zeroed above the edge. This function plus the ability to control table movement to fractions of a thou transforms your machining precision. It was the best money I spent. Of course, it's then you have to wonder how this digital precision could be automated - that's CNC.... Murray Edited By Muzzer on 21/05/2016 01:02:26 |

| John Reese | 21/05/2016 03:28:58 |

1071 forum posts | I have an AccuRite on my Bridgeport clone. It has lots of functions I never use. The 1/2 function is the most used. I occasionally use the bolt circle and hole pattern functions. I have used the in/mm conversion a couple times. The rest of the functions do nor interest me at all. A badly translated instruction manual destroys the usefulness of the DRO because one can't understand the instructions. You may want to play around with the buttons until you figure out the functions I just mentioned. They are really the only ones you need. If you have CAD then the bolt circle and hole patterns are not really needed. I am going to purchase a DRO for a mini mill. I plan to buy from DRO Pros because of the support they offer. I can talk to a real person located in the US to get my questions answered.

|

| jimmy b | 21/05/2016 06:08:00 |

857 forum posts 45 photos |

This one page did a better job than the manual! Jim |

| Bernard Wright | 21/05/2016 07:02:40 |

90 forum posts 16 photos | Thanks for the link Jim. Bernard. |

| JasonB | 21/05/2016 07:39:05 |

25215 forum posts 3105 photos 1 articles | Well if you will get other people to make your engines for you it's hardly surprising you don't use the DRO much I very rarely do any layout work on a part, tend to locate one edge and zero the axis, locate opposite edge and use 1/2 function which will give me ctr between the two edges and work from there. Metric Imperial is as you say useful depending on the job. Next most used is PCD, enter the position of the ctr of the circle (usually 0,0) then fill in the rest - diameter, No of holes, start & stop positions) and it will then give you the position of each hole in turn. Much easier than using Zeuz tables. Absolute and Incremental can be useful, the absolute can be used to move around the main part and say locate the ctr of a feature, then switch to absolute and layout holes, pocket etc from that point. I have only used the ARC function a couple of times to mill curves and that is hard to understand in the manual. You can mill features you can't easily do on a Rotary table Holes along a ling, again only used once or twice. Anything else is obveously even less used as I can't think of the other functions. J

Edited By JasonB on 21/05/2016 07:40:46 |

| Bob Brown 1 | 21/05/2016 10:31:32 |

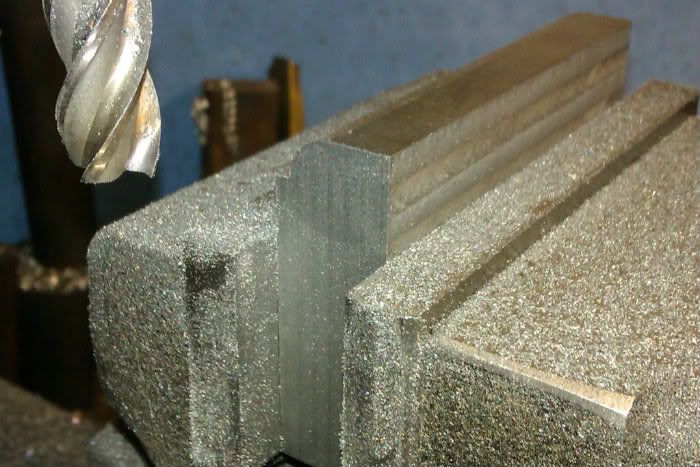

1022 forum posts 127 photos | I use the DRO for things like position and depth and also hole positions. Rather than mark out a part just mount it in the mill and drill to a set of coordinates like this or pony truck side frame. |

| Paul Lousick | 21/05/2016 10:41:36 |

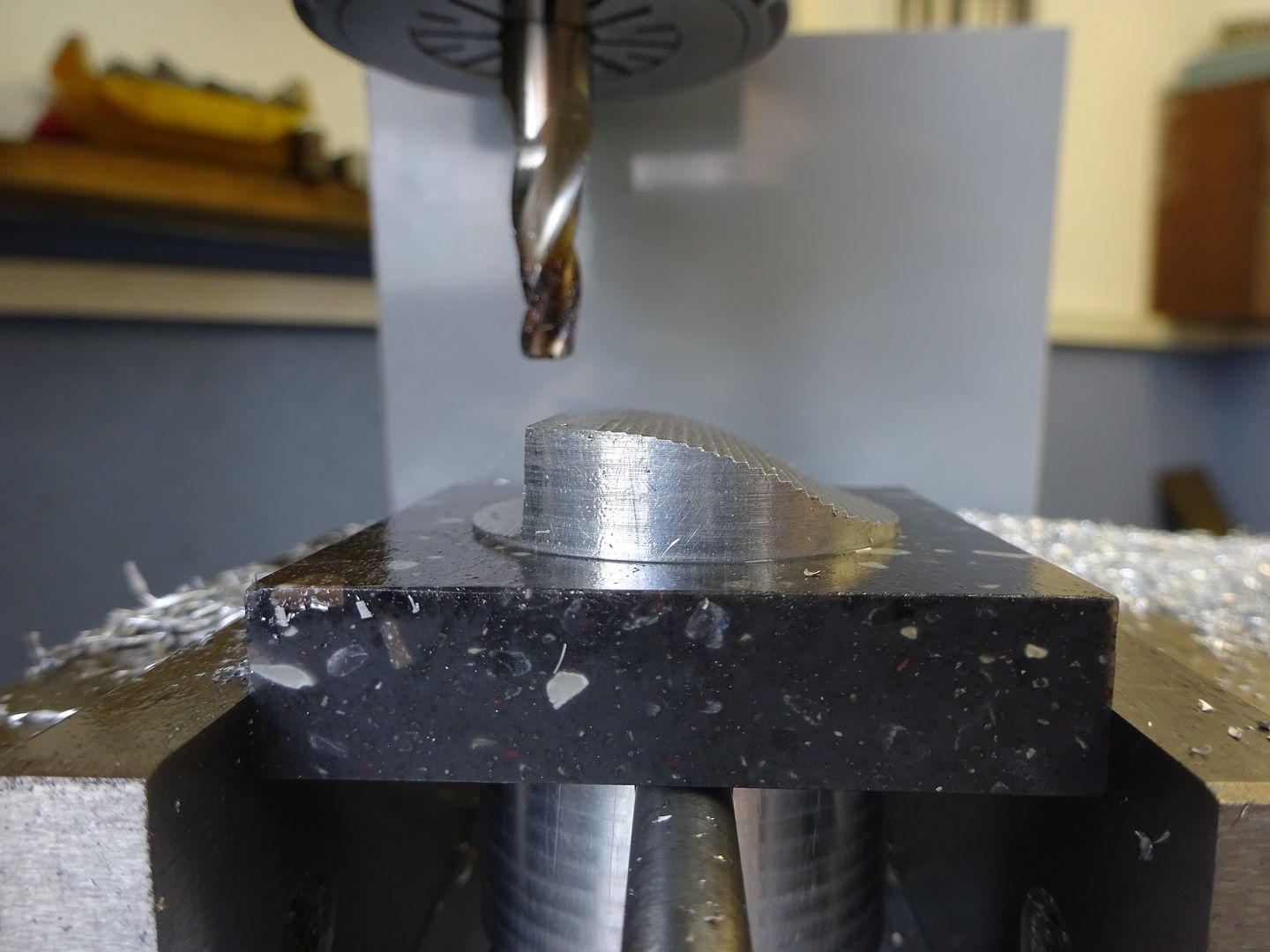

| 2276 forum posts 801 photos | After problems with some of the cheaper DRO's, I invested in some better ones from Easson for my mill. Best investment that I have made. Makes machining so much easier. A DRO is also great for accurately measuring equipment. I used it to measure the steam chest for my traction engine so I could model it in 3D CAD by clamping the casting on the mill and mounting a pointer in the drill chuck. Measurements could be taken in x, y and z directions with reference to a common datum. Lots of good instruction videos on Youtube + Easson DRO. Paul. Edited By Paul Lousick on 21/05/2016 10:48:53 |

| Clive Foster | 21/05/2016 12:19:13 |

| 3630 forum posts 128 photos | In total agreement concerning the near incomprehensibility of the Sino documentation. The PCD function is about the only advanced one I use regularly although the curve one has come in handy occasionally, usually when I need a pair of curves of different radii and centres on the same job. If you have the patience its about the best way of getting a clean internal intersection between two curves. Definitely a function to be used only when the cool, calm, collected and really patient tanks are full! Little gotcha with the PDC function, on my SDS2MS it only works in metric units. Dunno about other versions. I always get muddled as to how many holes to enter. Done 5 rather than the 4 I expected a time or tool! Usual "don't use it quite enough to really get it nailed" thing. Hafta look into the 1/2 function. So obviously useful but I've never used it in the 7 or so years I've had the DRO on my Bridgeport. Instruction book fatigue must have set in before I got that far in, probably didn't help that I got used to a simpler system on the square column Chester Lux style mill I had before. Same with absolute & incremental settings I guess. Obviously handy but another thing for the folk really familiar with the beast. Can see too many ways of getting all fudged up it not careful. My zero positions are cent for centre of table with standard ram extension and I usually put things back to zero before turning off the power. Paranoid. Nope I know the gremlins are out to get me. Keep contemplating the possible advantages of going for a full 4 axis system with another scale on the quill. I have a BW Electronics pull wire sensor fitted which is really neat and very useful but sometimes full integration between quill and table Z axis would be useful. Current technique is to scribble on the magnetic whiteboard beside the machine which works well enough unless I have an A3 drawing up which rather restricts scribble area. I have a spare scale too as I was unsure whether I would fit the Z on the quill or knee. Clive. |

| Ajohnw | 21/05/2016 12:58:25 |

| 3631 forum posts 160 photos | I haven't got a dro but do notice what people actually use which Jason summed up. By arc I assume he mean step approximation that can be cleaned up by hand later - to produce something llike the curved end of hinge like parts. I can't see much point in them on a lathe but am at times seriously tempted to fit one to my mill. There is a problem - I like the look of the Newall rod type which are a bit expensive. However I wouldn't be going for some cumbersome idiosyncratic display / controller containing software written and documented by monkeys I would be going in this direction.

To me a tablet is a better option as it can have all sorts of other workshop related things in it. John - |

| JasonB | 21/05/2016 13:31:04 |

25215 forum posts 3105 photos 1 articles | John, a couple of curved parts done using the dro, think I use a 0.020" step eg whatever you move x&z teh hypotinuse will be 0.020". Teh advantage of doing it this way is you get a crisp internal corner and can also do longer curves where a milling cutter would not have the reach.

And a different radius on teh end

Then as you say a quick clean up to get rid of teh machine marks

You can also use your CAD package to work out offsets at regular intervals which makes it easy to mill profiles, these were 1mm steps

|

| steamdave | 21/05/2016 13:35:59 |

| 526 forum posts 45 photos | Some very interesting responses there, gents. Many thanks for your inputs. May be I'm not the only one after all that only uses the DRO as an electronic ruler. Like the idea of the 1/2 function. Usually what I do is measure the width of the piece, touch off one side and move the table 1/2 the width, also the hole PCD function would save setting up the rotary table each time. What would be useful would be to save the position of the fixed vice jaw in memory so that I wouldn't have to find it each time after resetting Y during machining operations. Think that's covered in Jimmy B's link. Some useful info there when I get time to digest it. Dave

|

| Ajohnw | 21/05/2016 14:07:41 |

| 3631 forum posts 160 photos | I've seen a rather dismissive post about the tablet dro I linked to posted on here. Rather than just accepting the comments in it this page might be of interest

My understanding of how Yuiri's system works is that the interface board provides the intelligence - not the encoders and the android part does the number crunching where needed plus the display. John - |

| jimmy b | 21/05/2016 14:48:40 |

857 forum posts 45 photos | I wonder if the rad feature could be used on a lathe in a similar way.

I only ever use it for "point to point".

Does any one use it on a lathe to rough out rads? |

| Muzzer | 21/05/2016 14:49:51 |

2904 forum posts 448 photos | Clive - I have scales on both the knee and the quill. Can change over in seconds by simply swapping the plugs over, although 99% of the time it's the quill that is used. Photos in my link above show them both. Steamdave - I recommend you figure out use of the 1/2 function. It's actually pretty easy and intuitive. Works best with a simple edge finder (mine's 4mm dia so I can quickly move 2mm to reach centre distance). I have to admit I had an edge finder for ages but was too old and fat and stupid to figure out how to use it. Here's a useful explanation from Tom's Techniques. It's devastatingly quick and accurate when you combine it with a DRO. Looking back you wonder how you managed to bodge your way through... BTW, on his DRO, it's called "midpoint" instead of "1/2" Edited By Muzzer on 21/05/2016 14:54:27 |

| Gray62 | 21/05/2016 16:12:47 |

| 1058 forum posts 16 photos | Posted by Ajohnw on 21/05/2016 14:07:41:

I've seen a rather dismissive post about the tablet dro I linked to posted on here. Rather than just accepting the comments in it this page might be of interest

My understanding of how Yuiri's system works is that the interface board provides the intelligence - not the encoders and the android part does the number crunching where needed plus the display. John - John, where is the dismissive post? I've just put together one of Yuriys touch DRO systems for my mill, I played around with an MSP430 launchpad on a breadboarded system for a while to evaluate the hardware/software. I've since purchased one of the quadrature boards from Yuriy as this is not only a more robust solution (and I can't be bothered making pcbs up these days) but it also puts some funds back to him to support further development. I have to say, I am very impressed with the system, after re-wiring my ancient Mitutoyo glass scales with 9 pin d-sub connectors, hooked it all up, calibrated and everything works very well. Just need a decent case to house the interface board and devise a holder for the tablet. I'm using the wife's now redundant Kindle fire HD with a custom ROM installed so it behaves like a proper android device (kitkat 4.4) |

| Muzzer | 21/05/2016 20:39:53 |

2904 forum posts 448 photos | That's annoying. I've been trying to flash my Eepad Transformer with Katkiss 5.1 ROM but keep falling at the first (unlock) hurdle. Seems you have to get Asus to change some online database before it will allow itself to be unlocked. When running the original Icecream Sandwich it is painfully notchy and slow but is apparently transformed(!) by the update. Nothing's easy - another job for the list... |

| Neil Wyatt | 21/05/2016 21:39:27 |

19226 forum posts 749 photos 86 articles | Posted by Muzzer on 21/05/2016 20:39:53:

That's annoying. I've been trying to flash my Eepad Transformer with Katkiss 5.1 ROM but keep falling at the first (unlock) hurdle. Seems you have to get Asus to change some online database before it will allow itself to be unlocked. When running the original Icecream Sandwich it is painfully notchy and slow but is apparently transformed(!) by the update. Nothing's easy - another job for the list... I thought all the fun of these free OS's was getting them to work Neil |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Might be an option - it can be compatible with all sorts of scales. Throw the difficult one away and use that.

Might be an option - it can be compatible with all sorts of scales. Throw the difficult one away and use that.

Register

Register Log-in

Log-in