Sawing Plate

How to saw parts from aluminium plate

| Philip Borland | 24/09/2022 10:37:28 |

| 10 forum posts 14 photos | I am planning to build the grasshopper beam engine currently being featured in ME. The text states “cut out the blanks, ideally with a bandsaw”. I have both a horizontal metal cutting bandsaw with coolant, and a vertical bandsaw I use for woodworking. I cannot see how I would hold the plate on the horizontal bandsaw, or how I would cut it on the vertical bandsaw without lubricant as I do not want to use coolant or lubricant on my wood saw. Any guidance appreciated |

| DC31k | 24/09/2022 10:46:11 |

| 1186 forum posts 11 photos | Does your aversion to lubricant extend to wax or a wax-like material? Beeswax, candle wax, etc. A trade name seems to be Addiwax. Hoover it out before you start and after you finish. Put a new blade on when you finish and keep the old one for future metalworking. |

| Jelly | 24/09/2022 10:56:49 |

474 forum posts 103 photos | If the surface speed is appropriate, and you're using blade of an appropriate tooth count then I generally find lubricant on a vertical bandsaw unnecessary for cutting mild steel. Using an M42 bi-metal blade will make an appreciable difference to blade longevity and cope better with the higher surface speeds of a bandsaw optimised for wood. Tuff-Saws are my preferred source of blades, and offer a well designed Vari-Tooth Bi-metal blade which has additional room for chips compared to conventional designs, resulting in less friction and heating anyway.

Alternatively PP Profiles offers a very inexpensive laser-cutting service for steel, and if you send them the drawing and a specification for the thickness and grade of steel, they will get you a quote back the same day. I generally use them for any complex shapes as it's usually more economical than buying plate from the stockholders and cutting myself with the torch (which itself is far less faff than using a bandsaw).

|

| Philip Borland | 24/09/2022 11:18:59 |

| 10 forum posts 14 photos | I have spent a little time researching on YouTube and it would appear that a much larger pitch is required for a vertical bandsaw. A couple of them show 4 TPI, which is much greater pitch than I have tried in the past - but it co-insides with the advice above about the Tuff-Saws. What TPI would you recommend for 10mm Aluminium plate ? What would you use for Mild Steel ? |

| Nick Wheeler | 24/09/2022 11:42:17 |

| 1227 forum posts 101 photos | Have you considered a decent jigsaw and WD40 as a lubricant? |

| Tony Pratt 1 | 24/09/2022 11:50:45 |

| 2319 forum posts 13 photos | I can't recall ever using coolant on a band saw, just have a go with the blade you have got at the moment. Tony |

| Clive Brown 1 | 24/09/2022 11:52:33 |

| 1050 forum posts 56 photos | A bandsaw intended for wood will almost certainly have a blade speed that is too high for good general metal cutting but you might get away with aluminium. My home-made bandsaw runs at about 150 ft/min and uses the 1/4" carbon steel blades sold for DIY saws such as the Burgess etc. It cuts everything I need except I don't use it on stainless steel. My standard blade is 14 tpi 'cos that's the size Screwfix seems to stock mostly, and that's used for anything up to 1/2" mild steel, although that is pushing it perhaps. I've never used any form of lubricant. |

| not done it yet | 24/09/2022 11:52:52 |

| 7517 forum posts 20 photos | 4TPI will only have one tooth in the workpiece for some of the time. Not enough, so ignore those on youtube that suggest that tooth count is at all appropriate. One needs to be selective as to what you-tubers are competentband which might be numpties. Is your woodworking bandsaw designed for timber? If so, the surface cutting speed is likely far too high for metal. 10 TPI would suffice, I would have thought. |

| Jelly | 24/09/2022 12:05:27 |

474 forum posts 103 photos | Posted by Philip Borland on 24/09/2022 11:18:59:

I have spent a little time researching on YouTube and it would appear that a much larger pitch is required for a vertical bandsaw. A couple of them show 4 TPI, which is much greater pitch than I have tried in the past - but it co-insides with the advice above about the Tuff-Saws. What TPI would you recommend for 10mm Aluminium plate ? What would you use for Mild Steel ?

My experience has been that TPI is more or less set by workpiece thickness independent of material, so it would be the same for both. If you're cutting aluminium then you will be fine with the cheaper carbon steel blades, and may get away with using a wood blade if you want to chance your arm to get it done quickly.

Tuff-Saws also has a handy reference guide on choosing metal cutting bandsaw blades buried on their website; which I often use that as the starting point when selecting a blade (I keep a bunch of them on a hook, but can never quite remember what's most appropriate for what, I should probably put a chart behind the hook).

In practice you can "get away with" using a blade which is a bit finer than is really ideal most of the time, but not using too coarse a TPI on a thin workpiece (noise, terrible cut quality, broken teeth, blades jumping off bandwheels, etc.) So I would err to the finer side of what's considered appropriate if you're just buying a blade for a one off job.

Edit: accidentally linked to a vacuum cleaner on EBay rather than the reference page. Edited By Jelly on 24/09/2022 12:07:33 |

| JasonB | 24/09/2022 13:14:43 |

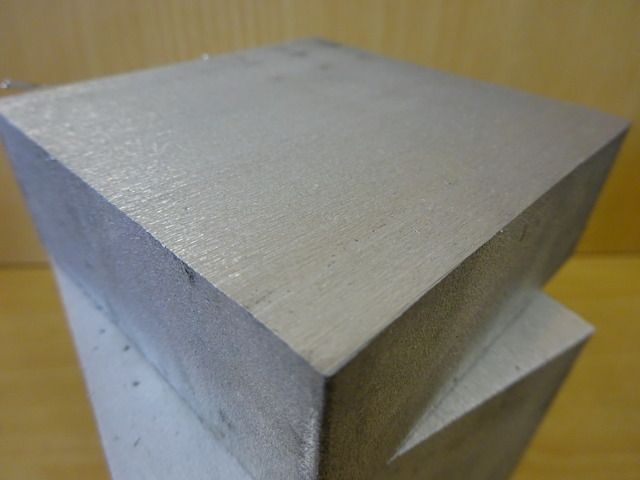

25215 forum posts 3105 photos 1 articles | I use my old woodworking bandsaw for cutting sheet/plate non ferrous and aluminium at the speed it cut wood at and with the same blades I used for wood. Prior to getting my Femi band saw I also used it to cut thicker section aluminium without too much of an issue. Both saws are used dry. Here is a bit of 3" square 6082 done with the woodcutting bandsaw.

Tpi for plate will be much the same as it would be for sawing by hand, aim for at least two teeth in contact with the work. I think that bit of ali was done with a 10tpi Starret bimetal wood blade. Or you could take a look at MEW 320 which has an article about converting a horz saw to vertical use then you will have lubricant and a saw better suited to cutting sheet/plate Edited By JasonB on 24/09/2022 13:19:22 |

| Jeff Dayman | 24/09/2022 13:27:19 |

| 2356 forum posts 47 photos | Just food for thought for the OP Philip: I have used my vertical bandsaw for about 30 years now. It is an all steel framed machine originally made by a local machine shop for wood cutting. I adapted it for metal cutting by adding a pulley speed reduction setup to slow the blade travel to 150 feet per minute. I have never used coolant. I use a 12 TPI high speed steel / spring steel bimetal blade by Starrett. The combo of 150 feet / min and the bimetal blade will cut steel, aluminum, copper, brass, bronze and stainless steel metals down to about 1/8" or 3mm quietly and quickly, and will also cut wood of any kind. If blade speed is higher than this it will be fine for wood but the blade will burn if used too fast on metals. My blades typically last a few years used several times daily at the noted 150 feet/min speed. The bimetal ones do cost more than cheap blades but they work and they last. |

| old mart | 24/09/2022 21:17:46 |

| 4655 forum posts 304 photos | The toolmakers at my old firm had a vertical bandsaw which was used for steel, aluminium, titanium, plastic and wood. All without any lubricant. The titanium was the favorite, especially when the apprentices were cut tooling lugs off it and the dust caught fire. Edited By old mart on 24/09/2022 21:19:02 |

| Dalboy | 24/09/2022 22:17:35 |

1009 forum posts 305 photos | I have also cut some ali on my wood cutting bandsaw but only when the blade is near it's end of life. Mine does have the option to slow it down with the change of the drive belt position which is what the instruction say that the slower speed is for metal cutting. That was before I brought a dedicated metal cutting saw |

| Peter Greene | 25/09/2022 01:56:08 |

| 865 forum posts 12 photos | Posted by Philip Borland on 24/09/2022 10:37:28:

I have both a horizontal metal cutting bandsaw with coolant, and a vertical bandsaw I use for woodworking.

Does your metal cutting bandsaw allow rotation to a vertical position to cut plate. Many do. I've just recently cut some 1/8" plate on mine. (it does help if you've made a larger support table for it). |

| David George 1 | 25/09/2022 09:18:50 |

2110 forum posts 565 photos | I have a Clarkson vertical band saw which is meant for woodwork and it is ok with a metal cutting blade to cut brass, copper and aluminium but it is too fast for steel, iron, stainless, and many other ferrous materials. I have never used a coolant or cutting oil ad the drive wheels have a rubber tyre which will be adversely affected by them. David |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in