Need to cut long thin strips of steel (& plastic) - e.g. with an angle grinder?

| John Smith 47 | 18/01/2022 17:51:52 |

| 393 forum posts 12 photos | Hello I hardly dare re-kindle this old thread....

Have any of you got one? Have you had much success in cutting straight lines with them by lining them up against straight edges ?

|

| Frances IoM | 18/01/2022 17:59:53 |

| 1395 forum posts 30 photos | you will need very forgiving neighbours as well as an expensive set of ear defenders. |

| Dave S | 18/01/2022 18:12:00 |

| 433 forum posts 95 photos | <popcorn>, <chair>, <beer> |

| Tony Pratt 1 | 18/01/2022 18:14:57 |

| 2319 forum posts 13 photos | Pass Tony |

| John Smith 47 | 18/01/2022 18:15:45 |

| 393 forum posts 12 photos | Posted by Frances IoM on 18/01/2022 17:59:53:

you will need very forgiving neighbours as well as an expensive set of ear defenders. IME, wax earplugs work well.

|

| Redsetter | 18/01/2022 18:24:21 |

| 239 forum posts 1 photos | Just order your materials cut to size. |

| Robert Butler | 18/01/2022 18:28:59 |

| 511 forum posts 6 photos | Topic well aired in previous thread, an insoluble problem. Robert Butler |

| Bezzer | 18/01/2022 18:49:32 |

| 203 forum posts 16 photos | I've just been cutting similar strips of 1.2mm stainless sheet and the weapon of choice was my wet wheel diamond blade tile saw. It's a cheap Plasplugs one about 12 years old and doesn't have a problem either freehand or with the guide giving a decent clean and accurate cut. Blades aren't that dear and last well. |

| noel shelley | 18/01/2022 18:59:45 |

| 2308 forum posts 33 photos | iF YOU CANNOT CUT A STRAIGHT LINE with a hacksaw then you do have a problem ! I would have suggested 4.5" X 1 or 1.5mm cutting disc in a small angle grinder. May be you need more practice. Good luck, Noel. |

| JasonB | 18/01/2022 19:18:57 |

25215 forum posts 3105 photos 1 articles | If you can't see the line to saw to what hope have you using any other form of free hand cutter given the added complications of eye protection and sparks flying about. Though maybe the sparks will make it a bit brighter either that or get some decent lighting in your work area. |

| Nick Wheeler | 18/01/2022 19:38:18 |

| 1227 forum posts 101 photos | Cleaning off the burr caused by any abrasive disc is going to be way more work, less accurate and more time consuming than just tapping any guillotine distortion straight. The guillotine will cut quicker too, and a long machine could cut several of your parts in one operation. |

| HOWARDT | 18/01/2022 19:48:47 |

| 1081 forum posts 39 photos | Have you looked at buying metal inlay strips. Would be a lot easier in the long run than all the cutting, deburing, and flattening. |

| John Smith 47 | 18/01/2022 20:05:38 |

| 393 forum posts 12 photos | Posted by noel shelley on 18/01/2022 18:59:45:

iF YOU CANNOT CUT A STRAIGHT LINE with a hacksaw then you do have a problem ! Yeah the lines are generally straight, just not in the correct direction! > I would have suggested 4.5" X 1 or 1.5mm cutting disc in a small angle grinder.

|

| John Smith 47 | 18/01/2022 20:12:53 |

| 393 forum posts 12 photos | Posted by Nicholas Wheeler 1 on 18/01/2022 19:38:18:

Cleaning off the burr caused by any abrasive disc is going to be way more work, less accurate and more time consuming than just tapping any guillotine distortion straight. The guillotine will cut quicker too, and a long machine could cut several of your parts in one operation. Tapping it straight?! > Have you looked at buying metal inlay strips.

|

| Brian Morehen | 18/01/2022 20:15:06 |

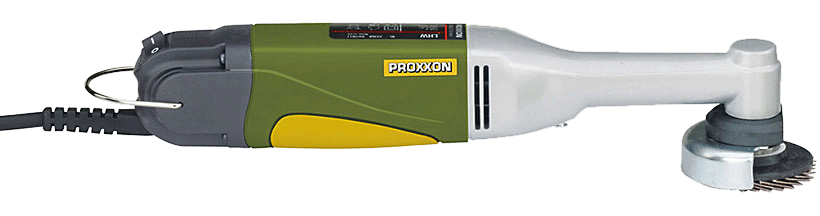

191 forum posts 11 photos | Have you looked at a Multi Tool ,I have cut most of the material you have mention using a straigh edge as a guide saw mine in Lidli some time ago and bought , with the right blades well worth the cost has saveded me loads of time . Regards Bee,M |

| pgk pgk | 18/01/2022 20:22:19 |

| 2661 forum posts 294 photos | If the lines you are trying to cut are generally straight, then adhesive tape as a guide would be more visible than scribing. You may also consider the method of printing patterns and spray adhesive them to the material. pgk |

| David Noble | 18/01/2022 20:28:35 |

402 forum posts 37 photos | I hesitate to enter the fray but a guillotine would do it. David |

| Nick Wheeler | 18/01/2022 20:45:06 |

| 1227 forum posts 101 photos | Posted by John Smith 47 on 18/01/2022 20:12:53:

Posted by Nicholas Wheeler 1 on 18/01/2022 19:38:18:

Cleaning off the burr caused by any abrasive disc is going to be way more work, less accurate and more time consuming than just tapping any guillotine distortion straight. The guillotine will cut quicker too, and a long machine could cut several of your parts in one operation. Tapping it straight?!

You need more experience then! Cuts made with grinding wheels on thin materials are horrible things. Doing one or two like would be OK, but more than a couple is not acceptable. I would always trade flattening an already straight cut over cleaning up one done by hand with a grinder. |

| Martin Connelly | 18/01/2022 20:57:30 |

2549 forum posts 235 photos | Buy a suitable mill and some slitting saws. Clamp the stock between two plates to support the material. The way this is going it will be cheaper than waiting for your perfect tool. The mill only needs to have a travel slightly more than your longest strip. Martin C |

| Ian P | 18/01/2022 21:10:57 |

2747 forum posts 123 photos | Posted by John Smith 47 on 18/01/2022 17:51:52:

Table saw, milling machine, slitting saws, angle grinders and almost anything else commonly (or uncommonly) available would struggle to cut a strip 1.4mm x 2mm. Doable with scalpel if Balsa wood was acceptable Ian P |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

or

or

Register

Register Log-in

Log-in