Member postings for John Smith 47

Here is a list of all the postings John Smith 47 has made in our forums. Click on a thread name to jump to the thread.

| Thread: Looking for a non-magnetic, strong, easily glued material |

| 30/04/2022 03:05:23 |

Congrats Don! J |

| 29/04/2022 16:50:02 |

Woohoo - hello People! I saw my name being mentioned.... so I thought I'd drop in. I have to tell you people, that this thread is absolutely HILARIOUS. I don't know if you gents are being serious or whether it is deliberate self-parody but this thread is absolutely heaving with self-parody. Poor you Don - now you know what I went through. The wolves won't let go until you publish every single detail of your life & your project... At which point expect to be told that your living in the wrong house and doing the wrong project!

Edited By John Smith 47 on 29/04/2022 16:52:30 |

| Thread: If epoxy adhesives fail to set within 24 hours, is there any hope that they will EVER do so? |

| 14/02/2022 15:55:35 |

Hello If Epoxy adhesives don't set properly within the first 24 hours, is there any hope that they will EVER set? Background Cause I was bonding at a slightly low room temperature (c.18C). But maybe Zap's Z-pox requires super-accurate proportions. J

|

| Thread: How can I bond ABS (plastic) to NRL (rubber)? |

| 28/01/2022 13:08:17 |

Posted by John Smith 47 on 27/01/2022 19:05:05:

Have any of you come across "Poly Kits" from Tech-Bond **LINK**

Too good to be true?

|

| Thread: Need to cut long thin strips of steel (& plastic) - e.g. with an angle grinder? |

| 28/01/2022 13:00:26 |

Posted by Neil Wyatt on 27/01/2022 22:09:12:

Posted by John Smith 47 on 25/01/2022 23:06:16:

Yes but - back to the question - how would you cut long thin straight lines through metal, using a device whose spinning wheel tugs you sideways when you make a cut?

Did you take a look at Mike Cox's design? Truth to tell, I couldn't find Mike Cox's design, although I did look for it online. Meanwhile, although I have now completed quite a lot of hacksawing by hand instead and the immediate for cutting of steel sheet has now passed... But thank you everyone for all your suggestions thus far. J |

| 27/01/2022 21:41:00 |

Posted by Stephen Cassidy on 26/01/2022 12:36:29:

Hi John there are lots of ways to make one, I took tips from a few projects to make mine. I haven’t motorised the axis on mine just yet . I'm not entirely sure how relevant it is but yes, J

|

| Thread: How can I bond ABS (plastic) to NRL (rubber)? |

| 27/01/2022 19:05:05 |

Have any of you come across "Poly Kits" from Tech-Bond **LINK**

Too good to be true?

|

| 26/01/2022 12:41:04 |

Posted by Michael Gilligan on 26/01/2022 11:31:35:

Posted by John Smith 47 on 26/01/2022 09:31:22: […] That said, the exact degree of elasticity is less important than the model falling to pieces due to shear forces overwhelming inadequate adhesives. . Despite the fact that we all know that adhesive tapes will peel … Did you ever try using the “heavy-duty, double-sided, carpet-fitting for the use-of” tape which I originally suggested ? Its mechanical properties must be pretty close to your requirements, although it permits no time for adjustment. . MichaelG. No, I confess I haven't tried any more adhesive tapes - neither double-sided or transfer tapes - because I have been unable to identify anything that sets hard. Do you have any specific suggestions/recommendations? |

| Thread: Need to cut long thin strips of steel (& plastic) - e.g. with an angle grinder? |

| 26/01/2022 11:21:18 |

> there is also a precision track saw that is incredibly accurate. TBH, I don't really have the workshop to do much making of my own tools, but what these guys have made caught my eye: Wonderfully inventive, no? Re this thread, to be completely honest, no only have I now done all the cutting I need the hard way (by hacksaw) but also for me personally, the physical size/scale of this whole conversation is getting rather out of control, as I am only looking needing to make precision cuts to create lengths of stainless steel sheet (c.1mm thick) that are about 20cm to 30cm long. Edited By John Smith 47 on 26/01/2022 11:27:19 |

| Thread: How can I bond ABS (plastic) to NRL (rubber)? |

| 26/01/2022 09:31:22 |

Posted by Michael Gilligan on 26/01/2022 00:57:00:

You might want to check that closing line, John … and correct it accordingly. ” Latex can be stretched to a length of about x2, whereas the latex can easily do x3. ” MichaelG. Good spot, but now too late to edit... Edited By John Smith 47 on 26/01/2022 09:32:33 |

| 26/01/2022 00:06:17 |

Back to this thread's question...

UPDATE I have been doing quite a lot of testing of materials. I now have found a less watery and slightly less aggressive type of CA/Superglue called Powerflex made by Loctite, which goes no more like a gel which would definitely help reduce spillage... Unfortunately, although the bond to rubber latex (NRL) is good/sometimes excellent - even a thin layer of the Powerflex causes swelling/warping of the latex, which then unavoidably seem to cause lumps & bumps in the outer surface of the RNL. See upper half of this photo:

In the lower half of the photo is my only real success so far, which is Elastosil E41 + NP2 primer, which combine to product a REMARKABLY good bond onto 1mm thick Silicone Rubber. In fact you may not really need to primer. |

| Thread: Can you recommend a "medium-speed" epoxy adhesive? (e.g. "30 minute" or "60 minute") |

| 25/01/2022 23:23:27 |

Crumbs. I rather hope that people here have better things to do with their lives that read "all" of John Smiths posts. |

| Thread: Need to cut long thin strips of steel (& plastic) - e.g. with an angle grinder? |

| 25/01/2022 23:06:16 |

Dave > Angle grinder: fast, noisy, messy, broad rough cuts. Inaccurate. My point was just that if used against a straight edge and with a fine metal-cutting blade, surely the Dremel DSM20 would be pretty accurate. Talking of which, out of interest, in order to increase accuracy on longer cuts, is it possible to get as an attachment an equivalent of the "riving knife"/"splitter" like table saws have? i.e. That would go into the cut left by the cutting wheel... to keep the cut straight. Edited By John Smith 47 on 25/01/2022 23:19:08 |

| Thread: How can I bond ABS (plastic) to NRL (rubber)? |

| 25/01/2022 22:57:07 |

But please try get your facts correct... Hey-ho. |

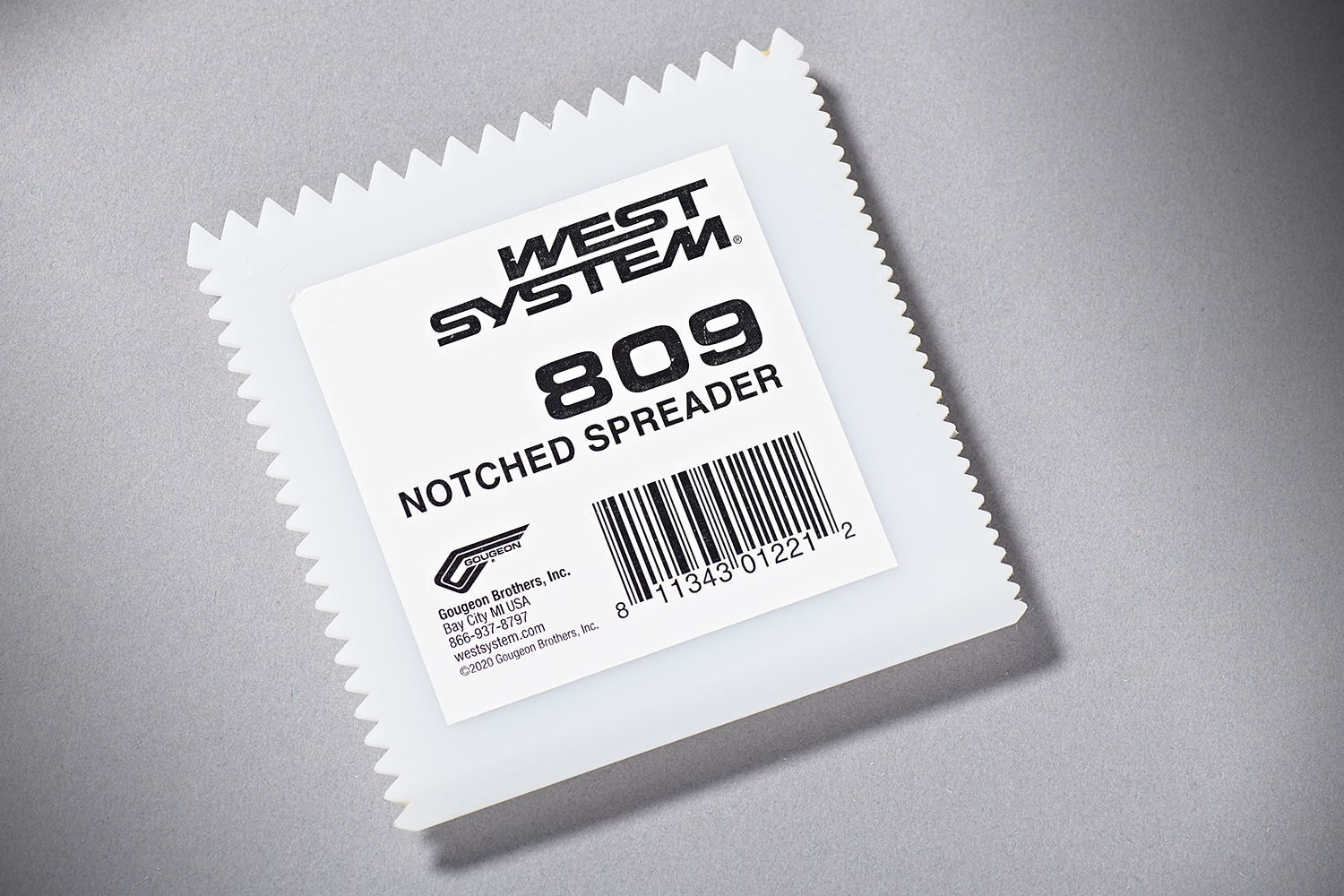

| Thread: Is it possible to by "100% non-stick" spatulas for spreading glue? (ideally made from teflon/FEP) |

| 25/01/2022 01:45:26 |

Btw, what are the pros & cons of using a notched adhesive spreader? Have you ever used them? |

| 25/01/2022 00:36:47 |

Posted by peak4 on 24/01/2022 22:43:13:

I've never seen them in the UK, at a justifiable price, though ebay shows US laboratory suppliers with them, so that might be somewhere to start. https://www.coleparmer.co.uk/i/ptfe-coated-lab-spatula-w-1-5-flat-taper-x-1-25-flat-round-ends-1-pk/0636911 Re buying sheet solid PTFE, I rather tempted. But it's not cheap stuff. What thickness do you think would suffice? 2mm? 3mm? I have no idea how flexible and/or physically strong the stuff is. Although the Ergo Square doesn't have a handle it it might have had merit in boing thinner & much more flexible... but either way, being PTFE I guess they would be dead-easy to wipe clean. Might work (??) J Edited By John Smith 47 on 25/01/2022 01:11:30 |

| 25/01/2022 00:32:23 |

To get clear, my understanding is that absolutely nothing will stick not a nice smooth surface of PTFT (Teflon) or FEP (its transparent close cousin). J

Edited By John Smith 47 on 25/01/2022 00:41:03 |

| 24/01/2022 22:26:56 |

Posted by Grindstone Cowboy on 24/01/2022 22:25:17:

You can buy packs of thirty or so plastic spreaders from various vendors very cheaply, use once then throw away? No good for the environment, of course. Rob > No good for the environment, of course.

|

| 24/01/2022 22:16:42 |

Posted by Robert Butler on 24/01/2022 21:49:25:

No, glue is very sticky. Robert Butler I have a plastic Plastic Spatula Set from Pinflair. https://www.pinflair.co.uk/pinflair-plastic-spatula-set J Edited By John Smith 47 on 24/01/2022 22:28:00 |

| 24/01/2022 21:19:56 |

Hello Is it possible to buy a spatula made for Teflon (or something similar that is totally non-stick) for spreading glue? Thanks

|

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

my silicone rubber is nothing like as elastic a natural rubber latex. Latex can be stretched to a length of about x2, whereas the latex can easily do x3.

my silicone rubber is nothing like as elastic a natural rubber latex. Latex can be stretched to a length of about x2, whereas the latex can easily do x3.

Register

Register Log-in

Log-in