drilling a bearing ball

| gerry madden | 06/06/2021 12:57:47 |

| 331 forum posts 156 photos | I want to make another measuring probe like the ones in the picture below. My first attempt to simply turn one up was ok but highlighted the need for the tip to be very spherical. So for Mk2 I want to put a hole bearing ball (1/8~1/4" Just looking for some guidance or comments on the following:- 1. I assume I'll need a carbide drill. With my speed limited to 3000RPM approximately how long should I expect this to take ? 5 mins or 50 mins ? 2. I will probably need to grind a small flat on it before drilling, but rather than do this off-hand then have the challenge of then re-holding the ball with flat in the right place and at right-angles to the drill, would it be better to attempt mill a flat with a carbide mill ?. I just cant see this going well ...... actually I have just realised, I have a diamond wheel I can mount in the mill so forget this one ! 3. ... or should I forget carbide and just go for a small diamond encrusted drill? I have seen torroidal shaped rubies for sale for this purpose but perhaps that can wait for Mk3, in the event that Mk2 is still lacking in some way. Gerry

|

| JasonB | 06/06/2021 13:02:52 |

25215 forum posts 3105 photos 1 articles | Unless you specifically need a hard ball get a stainless steel one as they can be drilled with HSS, spotting drill usually works for me to get the hole located and form a dimple for the drill bit. Annealing and rehardening after drilling a steel ball is another option Edited By JasonB on 06/06/2021 13:03:43 |

| Ady1 | 06/06/2021 13:17:54 |

6137 forum posts 893 photos | Holding it in a collet might make things easier |

| JasonB | 06/06/2021 13:36:36 |

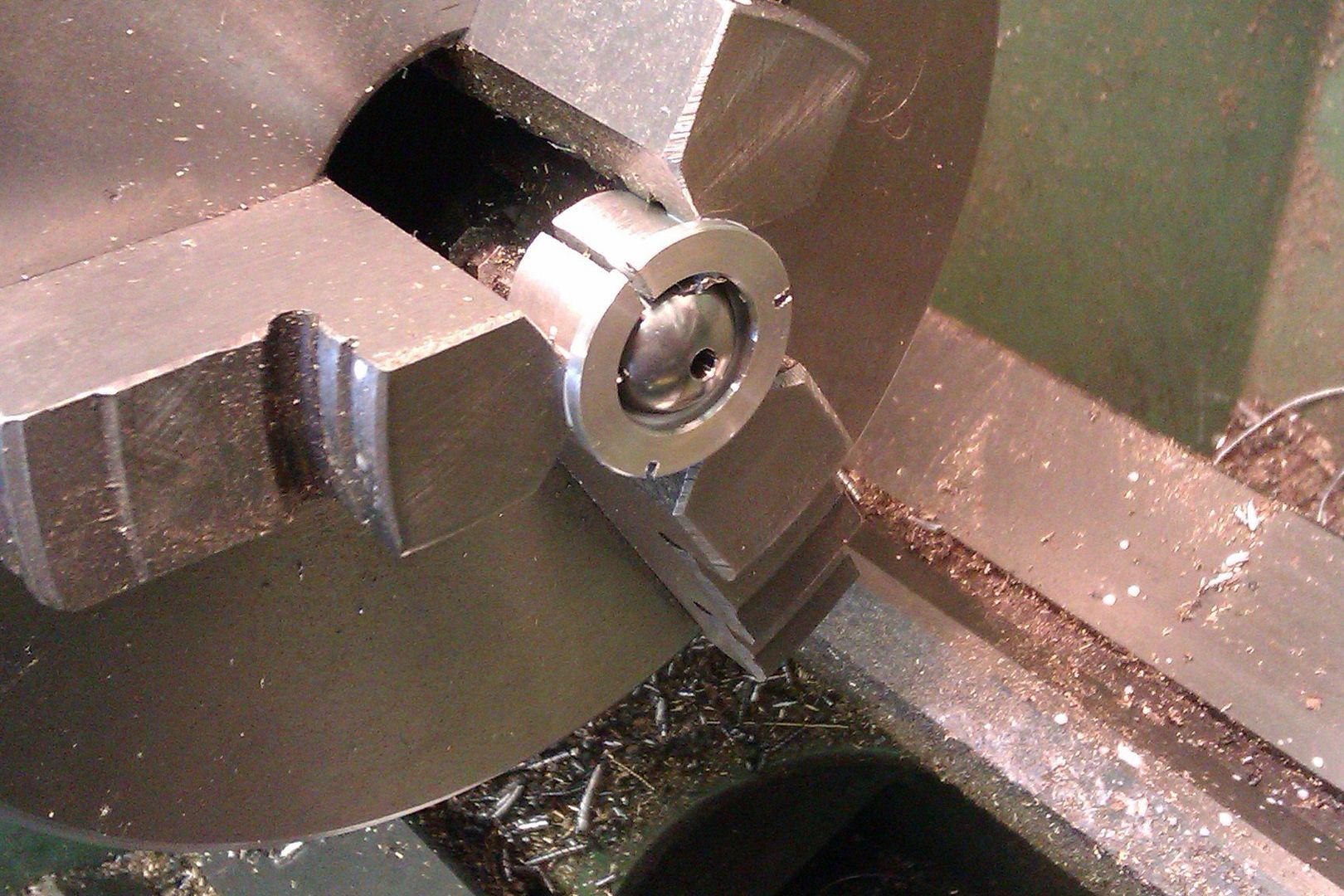

25215 forum posts 3105 photos 1 articles | Yes I usually do them in a collet or top hat bush

Small hard one being annealed

After drilling 1.0mm

|

| noel shelley | 06/06/2021 13:48:22 |

| 2308 forum posts 33 photos | Had to drill 3/8" holes in 2" balls, used carbide from tracy ! done in a myford S7. Noel |

| old mart | 06/06/2021 19:53:34 |

| 4655 forum posts 304 photos | I would run the solid carbide drill, preferably a stub, at slow speed, by hand. A flat would be an advantage if you can be sure it is perpendicular to the axis. Solid carbide drills come in various types designed for different hardness steels, I would look at the drills from Cutwel, or APT. If using a lathe, with the ball held in a collet, you could hold a diamond lap square in the toolpost and use the cross slide to rub a flat on the ball. It would take some time depending how fine the grit was. Edited By old mart on 06/06/2021 20:24:46 |

| Paul Lousick | 07/06/2021 03:32:18 |

| 2276 forum posts 801 photos | Even if you manage to drill a hole thru the bearing ball and glue it onto the turned body, how concentric will it be to the body ? Drilling a hole is not an accurate machining operation and attempting to do this on very small parts is even more difficult. (1/8"-1/4" diameter ball) If the probe is used for measuring it's better to turn everything in one operation for accuracy. Use a ball turning attachment if if you want a better sphere. Paul.

|

| Luker | 07/06/2021 07:06:48 |

230 forum posts 172 photos | I had to replace a lost probe point a few years back. Normal inner ball from a std bearing was annealed similar to how Jason suggested; the only difference, it was heated on some dry sand (with a little dishwashing liq) and pushed in with a wooden dowel. Was drilled and tapped using HSS. Any concentricity issues are inherently solved by the small centre drill breaking, but even with a wobbler type probe if you centre it with your finger on the ball all will be good... |

| Tony Pratt 1 | 07/06/2021 08:21:48 |

| 2319 forum posts 13 photos | Posted by Paul Lousick on 07/06/2021 03:32:18:

Even if you manage to drill a hole thru the bearing ball and glue it onto the turned body, how concentric will it be to the body ? Drilling a hole is not an accurate machining operation and attempting to do this on very small parts is even more difficult. (1/8"-1/4" diameter ball) If the probe is used for measuring it's better to turn everything in one operation for accuracy. Use a ball turning attachment if if you want a better sphere. Paul. I can't see that concentricity is relevant with this application? Tony

|

| David George 1 | 07/06/2021 08:25:06 |

2110 forum posts 565 photos | I used to repair probe and dial indicator tips. I would machine a dimple in the end of the item on the lathe, I would tin the end of the item with soft solder. The ball would be put in the dimple and a small wooden piece would hold ball down into the dimple, flux and reheated and soldered. I would then clean up the solder around joint and use. The joint was stronger than I first thought for soft solder but very few came off except by crashing into the job. The smallest I did was 1/32 diamiter ball. The balls were still hard and not affected by the heat of soldering. David Edited By David George 1 on 07/06/2021 08:27:02 |

| Nigel Graham 2 | 07/06/2021 09:31:23 |

| 3293 forum posts 112 photos | If you needed to drill a batch of balls, drill a countersunk hole in the end of a short bar but instead of soldering the ball in, hold it by a suitable union (or union-pattern) nut on the bar's appropriately threaded exterior. This will take a modest range of ball diameters. (Thinking on, and digressing somewhat, a variation using a counter-bored hole may give an alternative to the lantern chucks discussed on this forum not long ago, for shortening screws and rivets. In this case interpose a bush drilled to slide on the fastening's shank between its head and the inside of the union nut. ) |

| gerry madden | 07/06/2021 12:42:11 |

| 331 forum posts 156 photos | Thanks all for your comments. There are some good pointers there and things i hadnt considered. I might try annealing idea but then I will probably want to re-harden. Whether that causes a crack or two remains to be seen. Its a little more likely after its had a hole put in it because the residual stresses are less well balanced. But lets just see, it might well be fine. If it doesn't go well then I'll go the carbide route. I need the hardness because I'm measuring to a couple of microns and if the steel is soft one can easily indent or flat the ball by this amount by a little bit of careless handling much over time. As regards concentricity, as Tony suggests this shouldn't be a major concern in this application as I'm just measuring diameters of holes. I simply add the probe tip diameter to the measured diameter. But in any case just to be sure I will match the probe shaft to that of the hole in the ball after I've made it in order to minimise any eccentricity. I'll come back to you and let you know how its gone after my attempts. Gerry |

| old mart | 07/06/2021 18:00:02 |

| 4655 forum posts 304 photos | I have seen some ruby tipped indicator probe ends on ebay, made in China, similar to the one in Luker's photo. I cannot say how accurately spherical the rubies are. The ruby tipped type for CNN machines also come up for sale regularly, I don't know how expensive they are. |

| David George 1 | 07/06/2021 19:10:37 |

2110 forum posts 565 photos | These are a few I still have that were soft soldered in place. It is easy and well worth trying as the ball dosn't soften and and it would only take me half an hour to solder into place after dimpleing the stem. The one on the left has two flats ground on after soldering to get close to a step on a 0.015 " shoulder with my dial indicator. David

Edited By David George 1 on 07/06/2021 19:13:46 |

| Emgee | 07/06/2021 19:31:17 |

| 2610 forum posts 312 photos | Posted by gerry madden on 07/06/2021 12:42:11:

Concentricity, as Tony suggests this shouldn't be a major concern in this application as I'm just measuring diameters of holes. I simply add the probe tip diameter to the measured diameter. But in any case just to be sure I will match the probe shaft to that of the hole in the ball after I've made it in order to minimise any eccentricity. I'll come back to you and let you know how its gone after my attempts. Gerry When using an indicator to measure or centre a bored hole it is best to rotate the ball 180 degrees after taking the 1st reading, any eccentricity is then used on the opposing face being measured/clocked. Emgee |

| duncan webster | 07/06/2021 20:49:50 |

| 5307 forum posts 83 photos | A recognised technique for attaching thermocouples is to clamp them in place and discharge a big capacitor through the joint, thus spot welding the wire to the job. I wonder if this would work for attaching a ball to a probe? If anyone gets it to work let us know! Edited By duncan webster on 07/06/2021 20:50:06 |

| gerry madden | 27/06/2021 17:54:46 |

| 331 forum posts 156 photos | Jason, I was back on this one today and decided to try both methods discussed. So I've ordered carbide drills and in the meantime thought I would try annealing some 5mm balls. This didn't go too well. I heated two balls to bright redness and held them in that condition for about 1 or 2 minutes. Then over a similar time period let them cool down. When I tried to drill the first one with my favourite HSS spotting drill it made no impression at all. A quick check under the microscope showed the drill was now blunt and there was hardly a mark on the ball so it simply hadn't softened. Clearly I need to tweek the annealing process. What should I be doing ? The other issue is that the balls become quite scaled over from being heated, much more than I expected. Did you have a easy way to remove this scale without too much material loss ? In the carbide drill website it said something to the effect that chucks should have a runout of less than 5um ! I think this is a subtle way of saying expect to break some drills Gerry |

| Tony Pratt 1 | 27/06/2021 18:23:05 |

| 2319 forum posts 13 photos | 2 mins isn't long enough for annealing, I believe hot sand has been mentioned as a way of slowing the cooling? Tony |

| Macolm | 27/06/2021 21:26:05 |

185 forum posts 33 photos | A method I have not got round to trying to make a through hole is to mount the ball concentrically in the headstock, and use a Dremel or similar with a diamond point. The axis of the point rotation needs to be offset to just overlap the spindle centreline so that there is good cutting velocity over all the area of the desired hole.

Finesse will be needed and of course progress will be slow, but it may work. Either finish to diameter with additional passes of the point, or locktite in an insert. |

| Macolm | 27/06/2021 21:49:46 |

185 forum posts 33 photos | Repost:- edited to clarify.

A method I have not got round to trying for making a through hole is to mount the ball concentrically in the headstock, and use a Dremel or similar with a diamond point. The axis of the Dremel needs to be offset so that the point OD just overlaps the spindle centreline to provide good cutting velocity over all the area of the desired hole.

Finesse will be needed and of course progress will be slow, but it may work. Either finish to diameter with additional passes of the point, or locktite in an insert. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

and glue in on to the turned body. The hardness and smoothness of the ball will be advantageous also.

and glue in on to the turned body. The hardness and smoothness of the ball will be advantageous also.

Register

Register Log-in

Log-in