ARC NCIH Part Off Blade

| Blue Heeler | 23/07/2019 04:01:27 |

342 forum posts | ARC NCIH Part Off Blade Does anyone use one of these? |

| Thor 🇳🇴 | 23/07/2019 05:15:44 |

1766 forum posts 46 photos | Hi Jim, I have one for 2mm inserts and one for 3mm, they work well. Thor |

| Blue Heeler | 23/07/2019 05:21:19 |

342 forum posts | Cheers Thor. |

| Ketan Swali | 23/07/2019 06:38:25 |

| 1481 forum posts 149 photos | Hi Jim, This product and similar have been discussed on here and more recently on MEM. I cant find the links at present. As a summery, it is a bit like marmite. You either like it, get on with it and are happy, or the exact opposite. I personally happen to prefer the HSS Co8 type...which is also thinner than the carbide offering, at 1.5mm or 2mm. My reasons are down to fear. In the 'likeit' camp are people like Smithy from MEM, our Neil Wyatt, the late Sir John and many others. The main issues are - not so good for beginners, and as you have to run the machine relatively fast, the fear is there during parting, combined with rigidity issue around the machine components, combined with constant positive feed required for parting. The carbide blade/holder is not forgiving, and can break more easily if confidence levels are low. Great and easy to use for non-ferrous, but a lot of caution, skill and confidence required when using it on steel or cast iron. For every five buyers, three get on with the NCIH type, one plays with it with some fear, and one breaks it. Most beginners WILL most likely break it. Ketan at ARC

edited to correct spellings,... not had coffee yet. Edited By Ketan Swali on 23/07/2019 06:40:02 |

| JasonB | 23/07/2019 07:23:58 |

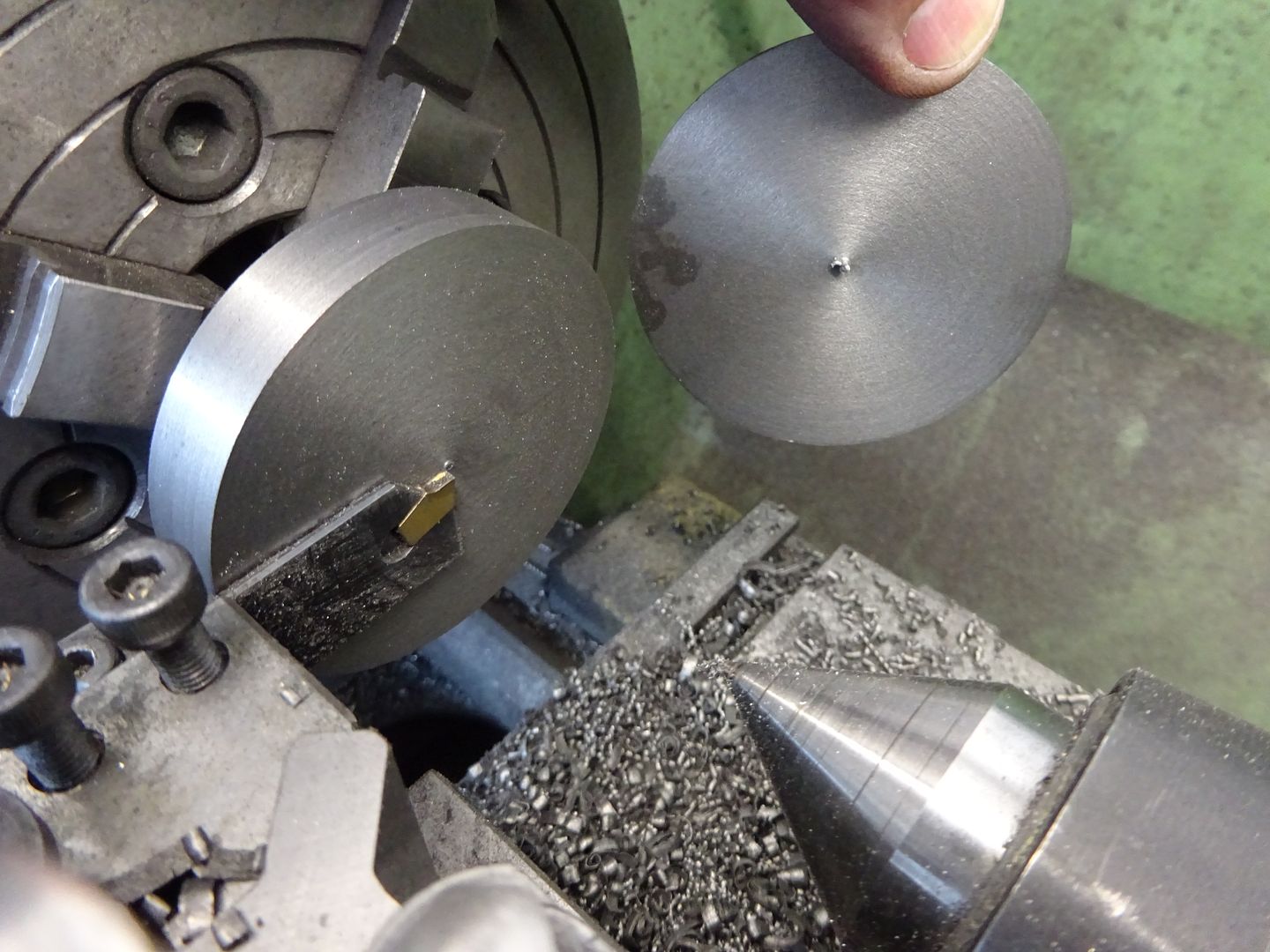

25215 forum posts 3105 photos 1 articles | I suppose the reason why some sellers of these holders supply two " blades" confirms what Ketan says about them breaking. Can't say I've damaged my similar type holder yet and am still on the first end of my holder with the "spare" still unused. It's my reach to parting tool for anything over 12mm, below that Like Ketan I use a HSS Co one particularly on brass/bronze and also have a 1mm wide insert tool that gets used quite a bit on smaller stiff. Slice of 70mm Cast Iron 1.5mm thick, and another smaller piece 0.5mm thick

|

| Blue Heeler | 23/07/2019 08:11:55 |

342 forum posts | Thanks Ketan & Jason for your replies. For the last 7 years I've been using Iscar GFN 3J IC354 inserts in an Iscar holder - Everything is great about them, except for the price (even though they do last for a long time, to buy a whole pack of 10 is $$$). They are around $18+ an insert and I was wanting to move away to something cheaper like the NCIH Part Off Blade. Many thanks again for the replies, I will do some searching for those MEM articles. Kind regards, Jim |

| Daniel | 23/07/2019 08:25:47 |

338 forum posts 48 photos | Hello All, I have only ever possessed the NCIH type parting tool (Type 26 x 3mm). To date it does everything I need it to. It is true, probably, that it takes a bit of getting used to. Tips do eventually wear out and/or break. But, to me, I still feel that the rapport usage/price is well within reason. As Jason has said, they can be used right up to capacity (80mm mild steel), with some care. A quantum leap, for myself, was when I switched to parting off under powered cross feed. Tip life increased tenfold !! ATB Daniel |

| David Standing 1 | 23/07/2019 08:32:37 |

| 1297 forum posts 50 photos | Posted by Ketan Swali on 23/07/2019 06:38:25:

Most beginners WILL most likely break it. Ketan at ARC

edited to correct spellings,... not had coffee yet.

First time I used mine......I broke it But I was doing something dumb with it that was, in hindsight, almost guaranteed to break it Just had my first mug of freshly ground coffee.....life is good |

| SillyOldDuffer | 23/07/2019 09:46:25 |

| 10668 forum posts 2415 photos | Posted by David Standing 1 on 23/07/2019 08:32:37:

Posted by Ketan Swali on 23/07/2019 06:38:25:

Most beginners WILL most likely break it. Ketan at ARC

...

First time I used mine......I broke it Me too! Still my preferred parting-off tool. Impressive when working well but not indestructible. Parting-off demands a lot of the lathe and the tool. Much easier to part-off on a heavy stiff machine than a bendy lightweight. Two main problems I get.

I've found all parting-off tools perform best with a steady feed when cutting correctly, which means getting the tool height, rpm and feed-rate right. Not too fast, not too slow, and definitely not jerky. Swarf clearance is vital. Proper lubrication helps, and the tool tip should be in good condition. Add it all together and it's not surprising parting-off goes wrong! Parting off is a balancing act. I found a lot more skill was needed to do it successfully on a Mini-lathe than my WM280, and I imagine anything heavier would be easier again, mainly because big heavy lathes are less likely to flex enough to allow the tool-tip to dip into a dig-in. What's really annoying is some lucky chaps don't have trouble parting-off. I suspect they have a steady hand, quick reactions and a natural feel for when tools are cutting correctly. The rest of us have to practice and experiment. I no longer expect disaster every time I part-off, but I'm not surprised that it goes wrong every so often. The design of NCIH holders may be deliberately weak:

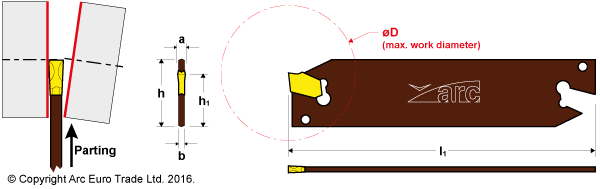

I suspect in commercial use where feed-rates are carefully calculated and automated, a dig-in means something really bad is wrong, and the tool is intended to break before the expensive CNC machine does. Still the best option for parting-off I've tried. Ketan's image shows the maximum parting-off diameter to be rather small: I invariably use the tool to take much deeper cuts than that! Dave

|

| JasonB | 23/07/2019 13:14:49 |

25215 forum posts 3105 photos 1 articles | Posted by SillyOldDuffer on 23/07/2019 09:46:25:

What's really annoying is some lucky chaps don't have trouble parting-off. I suspect they have a steady hand, quick reactions and a natural feel Dave, even with a silly old hand you should not have problems flicking the feed lever down on your 280, don't faff about hand feeding. That then gives you a free hand to drip a bit of paraffin onto aluminium so it does not stick

|

| old mart | 23/07/2019 13:59:11 |

| 4655 forum posts 304 photos | I have parting blades in 26mm and 32mm size, from 1.6 to 5mm wide. I wouldn't use the wide ones for parting, only grooving as the lathe isn't really stiff enough for parting, especially with steel. I ruined one end of my Kennametal 26mm by 1.6mm blade when the work moved in a three jaw chuck. A four jaw independent chuck is much more secure. Remember to check your jibs for tightness, and always lock the saddle when parting. I made a dedicated rear cut off block to hold 26 and 32 blades which bolts directly to the cross slide, with the blades inverted. I also added a rear saddle lock as the cutting forces are upwards. This is much stiffer than using a normal toolpost. I would never part off dry, soluble oil from a squirty bottle for steel, and WD40 or similar for aluminium. A great advantage of using the GTN inserts is that they are available from several sources, the best I know of is Korloy. I have some in 1.5, 2 and 3mm wide. Edited By old mart on 23/07/2019 14:01:45 Edited By old mart on 23/07/2019 14:09:56 |

| mark costello 1 | 23/07/2019 16:20:24 |

800 forum posts 16 photos | I have the best of both worlds. I mounted My insert cut off tool holder upside down, chips fall out. Every little bit helps. |

| SillyOldDuffer | 23/07/2019 16:44:37 |

| 10668 forum posts 2415 photos | Posted by JasonB on 23/07/2019 13:14:49:

Posted by SillyOldDuffer on 23/07/2019 09:46:25:

What's really annoying is some lucky chaps don't have trouble parting-off. I suspect they have a steady hand, quick reactions and a natural feel Dave, even with a silly old hand you should not have problems flicking the feed lever down on your 280, don't faff about hand feeding. That then gives you a free hand to drip a bit of paraffin onto aluminium so it does not stick

Well I do have a genuine problem. It's cowardice! I can't quite bring myself to try power feeding during parting-off. Now I've admitted the real reason I'll have to try it next time. Most disasters in the Duffer Workshop can safely be blamed on the operator...

|

| Howard Lewis | 23/07/2019 17:16:21 |

| 7227 forum posts 21 photos | It is only recently that I have had the courage to use power fine feed for parting off with a rear toolpost. As already said, the swarf falls away rather than accumulating, and so far, tempting fate, no dig ins! Forget to reverse the feed, from time to time, but soon rectified. Howard |

| Neil Wyatt | 23/07/2019 17:22:05 |

19226 forum posts 749 photos 86 articles | Just to confirm I like these. When I want to make little grooves I use HSS. In my experience confidence is the best aid to parting, (s)he who hesitates is lost! Neil

|

| Brian G | 23/07/2019 17:43:23 |

| 912 forum posts 40 photos | Powered cross feed is a great alternative to confidence (maybe not that much confidence, my freed-up hand sometimes hovers over the e-stop button). Truth be told It isn't thick material that REALLY bothers me, I have never successfully parted small stainless bar by hand as I start too slowly and work harden the surface, but under power it is a doddle. So far I have only parted with carbide tips in a grooving holder as I was nervous of the extra 15+ mm overhang on the QCTP that seems inevitable with the blade type holders, so for thicker material I have stuck to HSS, but this thread seems encouraging. Brian |

| Hollowpoint | 23/07/2019 18:21:39 |

| 550 forum posts 77 photos | Posted by Blue Heeler on 23/07/2019 08:11:55:

Thanks Ketan & Jason for your replies. For the last 7 years I've been using Iscar GFN 3J IC354 inserts in an Iscar holder - Everything is great about them, except for the price (even though they do last for a long time, to buy a whole pack of 10 is $$$). They are around $18+ an insert and I was wanting to move away to something cheaper like the NCIH Part Off Blade. Many thanks again for the replies, I will do some searching for those MEM articles. Kind regards, Jim Why not just swap the tips? The ones in the link look an awful lot like gtn3 tips. These are readily available and if you are prepared to wait they can be had for as little as 60p a tip from China. |

| Rik Shaw | 23/07/2019 18:32:53 |

1494 forum posts 403 photos | I use one of those generic insert holders that takes 3mm wide tips. I use an assortment of grades which I nab on ebay when they slip through in my price range. Lathe is Warco BH600G Rik Edited By Rik Shaw on 23/07/2019 18:34:22 |

| old mart | 23/07/2019 20:52:07 |

| 4655 forum posts 304 photos | Those of us lucky enough to have the use of a mill can make their own custom made rear toolposts, and dedicated conventional types. One of the reasons that I have never gone the QCTP route (apart from the cost), is the slight loss of rigidity as mentioned by Brian G. |

| Emgee | 23/07/2019 22:22:43 |

| 2610 forum posts 312 photos | Does anyone have a picture of the GTN insert removing tool, or a short description. ? Emgee |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in