Extracting a dowel pin from a blind hole

| Phil Pemberton | 28/01/2019 02:21:22 |

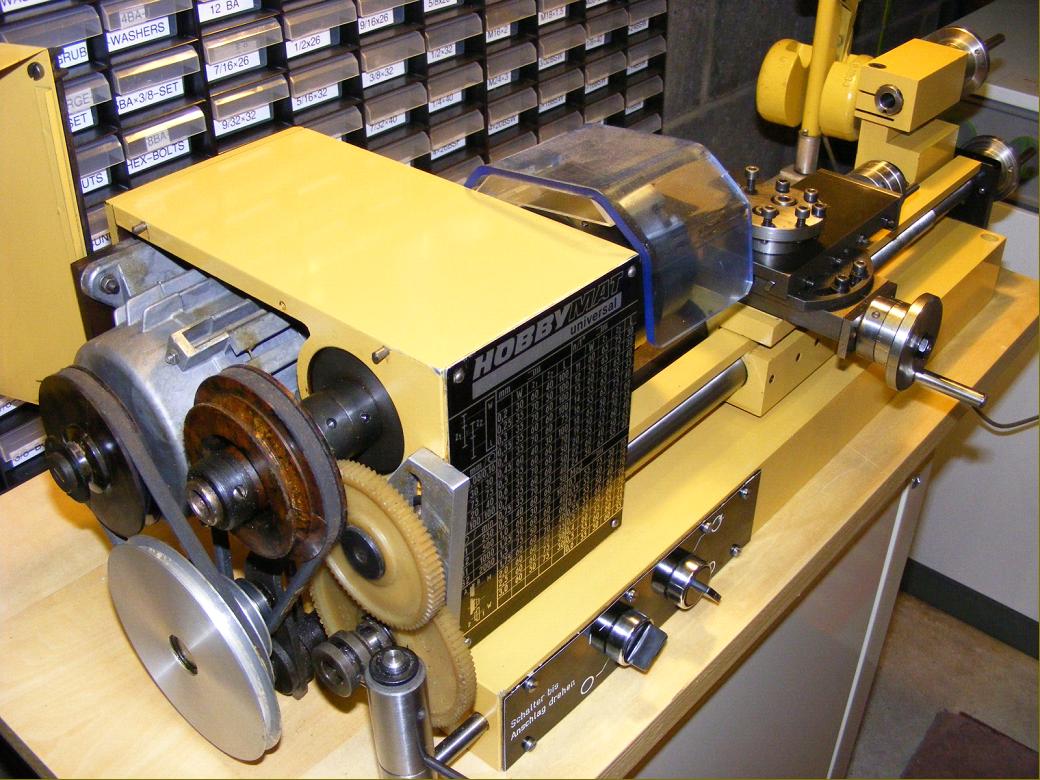

| 12 forum posts 2 photos | Hi all, Some of you might have seen my thread about the Hobbymat MD65 over in "Tools and Tooling". I've got a small problem with a metal dowel pin... There's a yellow support which the front of the carriage rests on. This is held in place with one dowel pin on the left, and two on the right. Sadly it appears the previous owner has managed to drive the pin into the blind hole deep enough that there's nothing to grab onto... this is making the support a bit unstable. Does anyone have any good tricks for getting these pins out? Right now my best plan is to turn a small cylindrical drill bushing from a piece of scrap and use that to guide a drill bit into the pin. Hopefully I can then use "something" (possibly a self tapping screw) to pull the pin out. Thanks, |

| John Reese | 28/01/2019 02:36:07 |

1071 forum posts | True dowel pins are through hardened. Yo will not be able st screw something into it. Can you drill through the other side of the part so you can get a punch on the pin? If that is not possible set it up on the mill and cut out the pin with a carbide end mil. |

| Phil Pemberton | 28/01/2019 02:43:28 |

| 12 forum posts 2 photos | Sadly not. I've drilled into the support bar behind the pin, but I can't get enough leverage to push it out. If I make the hole any larger, it'll compromise the support bar. The bar is about 50cm long (haven't measured it), 10mm thick and 20mm wide. Knocking a punch in from behind seems impossible. One other plan I had considered was to drill a hole in behind the pin at a steep angle - I need to have a think about the practicalities of this and how to repair the bar afterwards. |

| Hopper | 28/01/2019 04:19:46 |

7881 forum posts 397 photos | Some pics of what you are working on sure would help. Have you tried heating the "bar" with a propane torch to expand it and then bang it on the bench to shake the dowel out? You should have a try at drilling the dowel pin. It may not be a through-hardened pin. It may be soft enough to drill and tap to extract. Some pins are case hardened, so you might be able to Dremel the hard case off the end and then drill it. Other pins are just plain mild steel that could be drilled easily. Only one way to find out which you have... |

| Nimble | 28/01/2019 07:27:22 |

66 forum posts 6 photos | Could you apply a needle point grease gun to the already drilled hole and use the hydraulic pressure to force the pin out. Mechanics use a similar method to drive the spigot bushes out of a fly wheel,alternatively enlarge the through hole to a small pin punch diameter and fill with oil, then drive the pin punch into the through hole refilling with oil when necessary. Nimble Neil |

| JasonB | 28/01/2019 07:43:13 |

25215 forum posts 3105 photos 1 articles | Looks like part No12 on page 38 of the manual so no way of drilling and punching |

| Richard - | 28/01/2019 08:04:42 |

| 62 forum posts 7 photos | Morning, Try drilling the pin with a cobalt drill, what is the pin diameter?

|

| David George 1 | 28/01/2019 08:06:53 |

2110 forum posts 565 photos | Hi Phil try pushing some plastercine or similar material down the hole you have drilled behind the dowel then take a punch as near to size of the hole and give it a good thump. The hydraulic pressure should push out the dowel, top up the plastercine as necessary. David |

| Former Member | 28/01/2019 08:52:06 |

[This posting has been removed] | |

| Hopper | 28/01/2019 10:09:00 |

7881 forum posts 397 photos | Posted by JasonB on 28/01/2019 07:43:13:

Looks like part No12 on page 38 of the manual so no way of drilling and punching Aha. So the dowel is in the end of the long thin bar. Much clearer now. I think I'd be trying grinding the end off the dowel with a Dremel and trying to drill it out once through the hard skin. Most dowel pins are case hardened, not through hardened, so they retain the strength of the core steel under impact etc. We used to grind the ends off hardened dowels and drill and tap them for later extraction when using them to hold together press tooling, so it can be done if the pin is not through-hardened. |

| Howard Lewis | 28/01/2019 10:34:53 |

| 7227 forum posts 21 photos | If you can manage to drill a hole through the dowel, as already suggested try using hydraulic pressure to remove it. Hopefully, a pressure oil can will move it out. If this fails, is it large enough in diameter to tap? Probalby too small to screw in a stud, so that a sleeve and nut could then be used to extract it, without stripping the thread. But could you screw in a grease nipple? If so a good grease gun, preferably a side lever, or Wanner type, rather than a pom pom, should be able to apply sufficient pressure to force the dowel out. Howard

|

| Martin Connelly | 28/01/2019 13:16:59 |

2549 forum posts 235 photos | Find someone who can TIG weld a washer edge on to the dowel and pull the washer to remove the dowel. Martin C |

| Neil Wyatt | 28/01/2019 14:21:44 |

19226 forum posts 749 photos 86 articles | Count your losses and drill a pair of holes for a new pin? |

| ega | 28/01/2019 14:42:54 |

| 2805 forum posts 219 photos | Posted by Neil Wyatt on 28/01/2019 14:21:44:

Count your losses and drill a pair of holes for a new pin? Or cut your blessings? |

| I.M. OUTAHERE | 28/01/2019 14:59:07 |

| 1468 forum posts 3 photos | Before doing anything I would check to see if the pin is actually hardened by giving the end a rub with a file . You may be lucky and find it is a cheese grade pin ! If it is hardened then cut it out with a carbide end Mill . |

| Bazyle | 28/01/2019 15:36:41 |

6956 forum posts 229 photos | It is not a support bar, just a leadscrew guard of no value to the operation of the machine. Just cut it off and use it to make something else. Replace with a new piece of mild steel that will cost you less than the special drill. |

| Michael Gilligan | 28/01/2019 19:27:32 |

23121 forum posts 1360 photos | Posted by Bazyle on 28/01/2019 15:36:41:

It is not a support bar, just a leadscrew guard of no value to the operation of the machine. . Funny you should mention that, Bazyle I did wonder, earlier today, if folks should be looking at pp 42-43 ... but decided to see how the thread progressed. MichaelG. |

| JasonB | 28/01/2019 19:33:27 |

25215 forum posts 3105 photos 1 articles | Part 12 would seem to fit the given dimensions of 10mm x 20mm x 50cm, note my bold. Parts 27 on that page and the one before would be the 3 dowel pins that go into the ends of part12 Edited By JasonB on 28/01/2019 19:35:54 |

| Michael Gilligan | 28/01/2019 19:37:53 |

23121 forum posts 1360 photos | Posted by Phil Pemberton on 28/01/2019 02:21:22:

There's a yellow support which the front of the carriage rests on. This is held in place with one dowel pin on the left, and two on the right. . Hopefully, Phil will post a photo MichaelG. |

| JasonB | 28/01/2019 19:46:14 |

25215 forum posts 3105 photos 1 articles | Posted by Michael Gilligan on 28/01/2019 19:37:53:

Posted by Phil Pemberton on 28/01/2019 02:21:22:

There's a yellow support which the front of the carriage rests on. This is held in place with one dowel pin on the left, and two on the right. . Hopefully, Phil will post a photo MichaelG. Or just look at page 11 of the manual, whether the carrage actually rests on the bar or not I would not like to say but that is part 12. The paint doe snot seem to wear on used ones so maybe it just passes through that slot at the front of the carrage.

Edited By JasonB on 28/01/2019 19:51:20 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in