Parting off - again, sorry

| petro1head | 11/10/2018 10:55:11 |

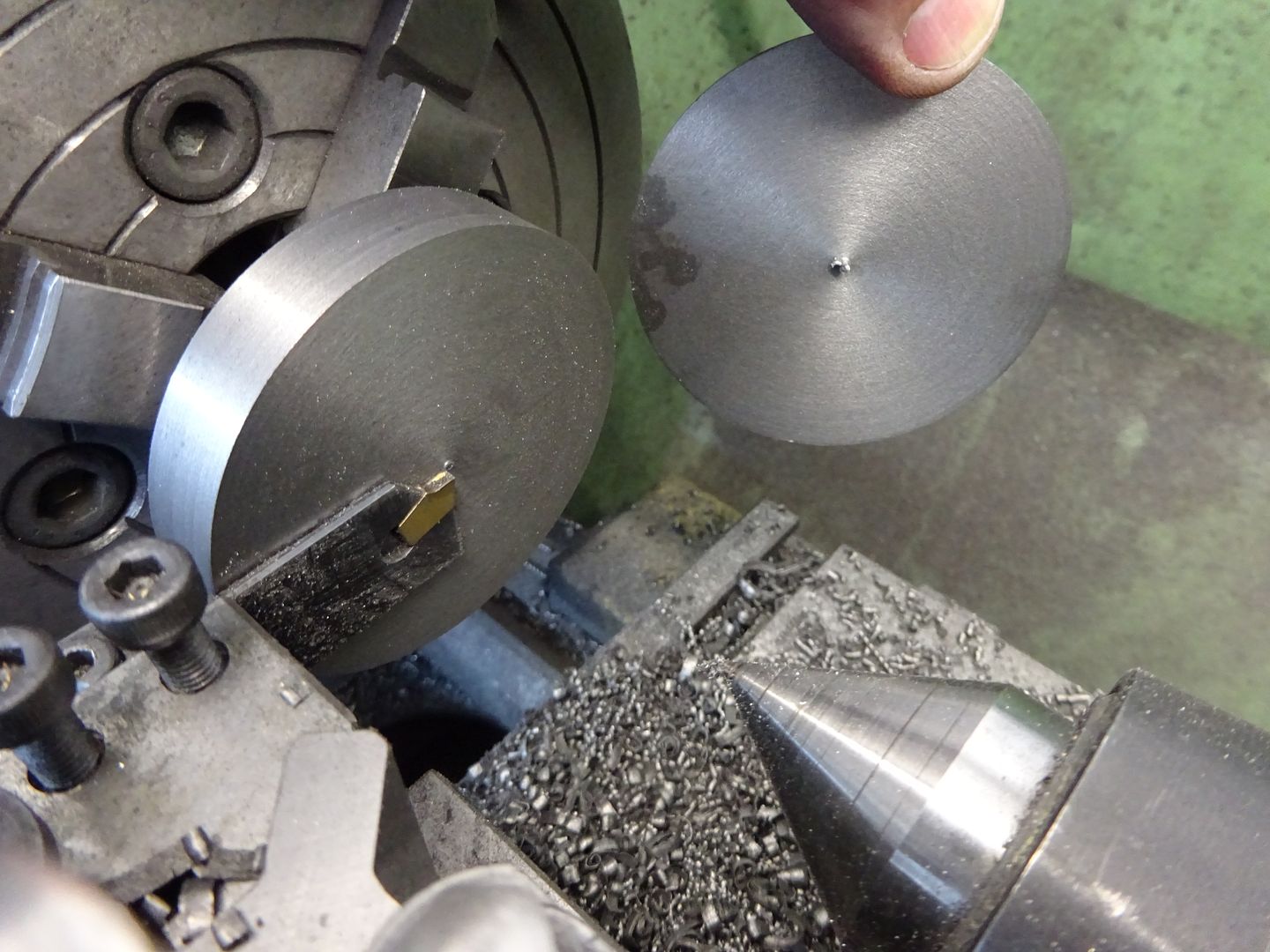

984 forum posts 207 photos | I am still strugling with parting off. I make sure the tool is square to the work. I use cutting fluid. However the tool seems to deflect This is the tool I am using So any idea why its defecting, too thin a tool, its 2mm. Would I be better using a 3mm tool instead? |

| not done it yet | 11/10/2018 11:02:04 |

| 7517 forum posts 20 photos | Do you lock the carriage and top slide? |

| Brian Sweeting | 11/10/2018 11:07:08 |

| 453 forum posts 1 photos | Reduce the amount of tool sticking out from toolpost may help a bit. |

| ega | 11/10/2018 11:12:02 |

| 2805 forum posts 219 photos | Assuming that the tool is indeed advancing at right angles, you could try swapping out the tip; the present one may be cutting unequally across its width. Difficult to say from the photo but it should be examined critically under a lens. |

| petro1head | 11/10/2018 11:14:53 |

984 forum posts 207 photos | Posted by not done it yet on 11/10/2018 11:02:04:

Do you lock the carriage and top slide? Good question, no

Problem is the dro scales cover the locking screws |

| petro1head | 11/10/2018 11:15:30 |

984 forum posts 207 photos | Posted by Brian Sweeting on 11/10/2018 11:07:08:

Reduce the amount of tool sticking out from toolpost may help a bit. Cant because its the right length for the work |

| petro1head | 11/10/2018 11:15:52 |

984 forum posts 207 photos | Posted by ega on 11/10/2018 11:12:02:

Assuming that the tool is indeed advancing at right angles, you could try swapping out the tip; the present one may be cutting unequally across its width. Difficult to say from the photo but it should be examined critically under a lens. So, easier to just try a new tip |

| JasonB | 11/10/2018 11:27:18 |

25215 forum posts 3105 photos 1 articles | On a deep cut you may find it better to set the tool projection so it will go half way and then set the tool further out of the holder to complete the cut. A 2mm blade should be OK, thats what I use and don't get any deflection. If one corner of the tip has become damaged or worn that will also tend to push it sideways |

| Oldiron | 11/10/2018 11:31:52 |

| 1193 forum posts 59 photos | Could be that you are using much to slow a spindle speed and too fast advancement. I find these tip tools cut much better at higher speeds. regards |

| petro1head | 11/10/2018 11:58:56 |

984 forum posts 207 photos | Posted by JasonB on 11/10/2018 11:27:18:

On a deep cut you may find it better to set the tool projection so it will go half way and then set the tool further out of the holder to complete the cut. A 2mm blade should be OK, thats what I use and don't get any deflection. If one corner of the tip has become damaged or worn that will also tend to push it sideways

Posted by Oldiron on 11/10/2018 11:31:52:

Could be that you are using much to slow a spindle speed and too fast advancement. I find these tip tools cut much better at higher speeds. regards What sort of speed would you advise? Edited By petro1head on 11/10/2018 11:59:32 |

| Brian Oldford | 11/10/2018 12:05:20 |

686 forum posts 18 photos | Fit a rear tool-post then all should be sweetness and light with great rejoicing in heaven and on earth. |

| JasonB | 11/10/2018 12:13:36 |

25215 forum posts 3105 photos 1 articles | What sort of diameter are you cutting as that will affect speed. I seem to manage OK without a rear post and a similar 2mm blade, 1/16" slice off 2.5" cast iron and less than a thou variation in thickness!

|

| A Smith | 11/10/2018 12:15:22 |

| 104 forum posts 4 photos | I use a 2mm inserted tip parting off tool with great success on my Myford ML7. It is fitted in a quick change tool holder. I used to struggle with parting off, things improved when I discovered the carriage lock! and again, years later, when I purchased the inserted tip tool from JB tools. I have a rear toolpost but haven't felt the need to use it, as yet. Andy |

| ega | 11/10/2018 12:30:27 |

| 2805 forum posts 219 photos | JasonB: Did you use tailstock support and if so at what stage did you retract the centre? |

| Howard Lewis | 11/10/2018 12:32:18 |

| 7227 forum posts 21 photos | You are not alone! But I make a rod for my own back, even with the saddle locked, by grinding the HSS tool with an angle on the front, to minimise a "pip" on the workpiece. I do not expect a slim tool, or tool holder not flex, so after parting off, I face the end of the work, which also gives a better finish. Any slight force will deflect the tool or the holder in the case of inserted tips. hence Jason's advice to cut a little, and then advance the tool, until the cut is complete. Parting off with the tool mounted on a back toolpost causes much fewer problems. Howard |

| HOWARDT | 11/10/2018 12:34:40 |

| 1081 forum posts 39 photos | I work on a Sieg SC3, use a HSS-Co8 parting blade clamped in a home made holder that clamps the blade in the side face. The blade has no top rake, only ground on the front. HSS-Co8 is much tougher than a straight HSS blade, the ones I use are I assume Chinesium but they work. When I first had the lathe I had a carbide insert holder, but gave up on it after having to use a HSS blade when the supplier was shut. Saddle is clamped to the bed, after positioning. Compund slide is tightened but not fully clamped, the reason for this is so I can make a wider cut than the single blade width. I do this so that the swarf clears the side of the blade, I take a plunge cut, then move slightly to the side to take a second as I move the blade in. Cutting speed is around 400RPM, dependant on diameter, adjust to suit diameter as you feel confident. Don't overhang the compound slide from the cross slide as this will allow movement on a small machine. I have cut unto 75mm diameter in steel, it took time but it did cut. Use a cutting oil to keep the tip cool, I use a spray cutting fluid from Toolstation. Most of my work is with steel, softer metals like brass and phosphor bronze are less of an issue. |

| petro1head | 11/10/2018 12:42:08 |

984 forum posts 207 photos | Posted by JasonB on 11/10/2018 12:13:36:

What sort of diameter are you cutting as that will affect speed. I seem to manage OK without a rear post and a similar 2mm blade, 1/16" slice off 2.5" cast iron and less than a thou variation in thickness!

38mm ali

|

| Mick B1 | 11/10/2018 12:59:16 |

| 2444 forum posts 139 photos | My two penn'orth: Looking at you photo of the tool, I'm thinking I can see a tiny wedge of support on the lower edge of the insert location that suggests the insert is skewed rightwards. Can't tell if the insert is properly vertical or not, but if it isn't the right-hand side of the tool might be rubbing, unable to cut, and so forcing the left-hand side to dig in further and deflect the supporting blade that way. The fact that there's also a significant bit of the support projecting forward underneath the insert suggests to me that there's summat up with its location. |

| JasonB | 11/10/2018 13:16:16 |

25215 forum posts 3105 photos 1 articles | I also noticed that Mick, maybe the holder has been twisted in a previous lock up. If you are cutting 38mm ali then why do you have a good 35mm plus of tool sticking out? I can see the "2" showing part way along which indicates 20mm projection and that is enough to go through 38mm stock. Speed wise put it in the slower speed range but run towards max 900-1000 and feed briskly. |

| Ron Laden | 11/10/2018 13:59:59 |

2320 forum posts 452 photos | Posted by JasonB on 11/10/2018 13:16:16:

Speed wise put it in the slower speed range but run towards max 900-1000 and feed briskly. I recently turned a set of buffers from 35mm dia ali and Jasons advice above is pretty much what I found worked for me using a 1.5mm HSS tool. Moving up to a 3mm tool I would avoid if my experience with one is anything to go by. If you are using a mini-lathe as I am I would argue that a 3mm parting tool is too much for them. I have a HSS 3.2mm tool and the lathe just doesnt like it, even with ali, I tried everything I could but it was not happy. Edited By Ron Laden on 11/10/2018 14:03:25 Edited By Ron Laden on 11/10/2018 14:18:05 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in