drilling a 20mmx 300mm Hole in cast iron

| Buffer | 09/05/2018 18:50:34 |

| 430 forum posts 171 photos | Hi all Does anyone know how to drill a 20x300mm hole in cast iron when I don't have a very long drill and I cant fit that and the work between centres in the lathe anyway so it will have to be in the pilar drill. Could I make something like a D bit or other cutter from silver steel? Would it last long enough and what shape should I use? Has anyone extended a drill bit and if so how did you do it, was it a success? Could I extend a blacksmith type of drill? Thanks for any help you might be able to give, I appreciate it. Rich

|

| JasonB | 09/05/2018 19:31:48 |

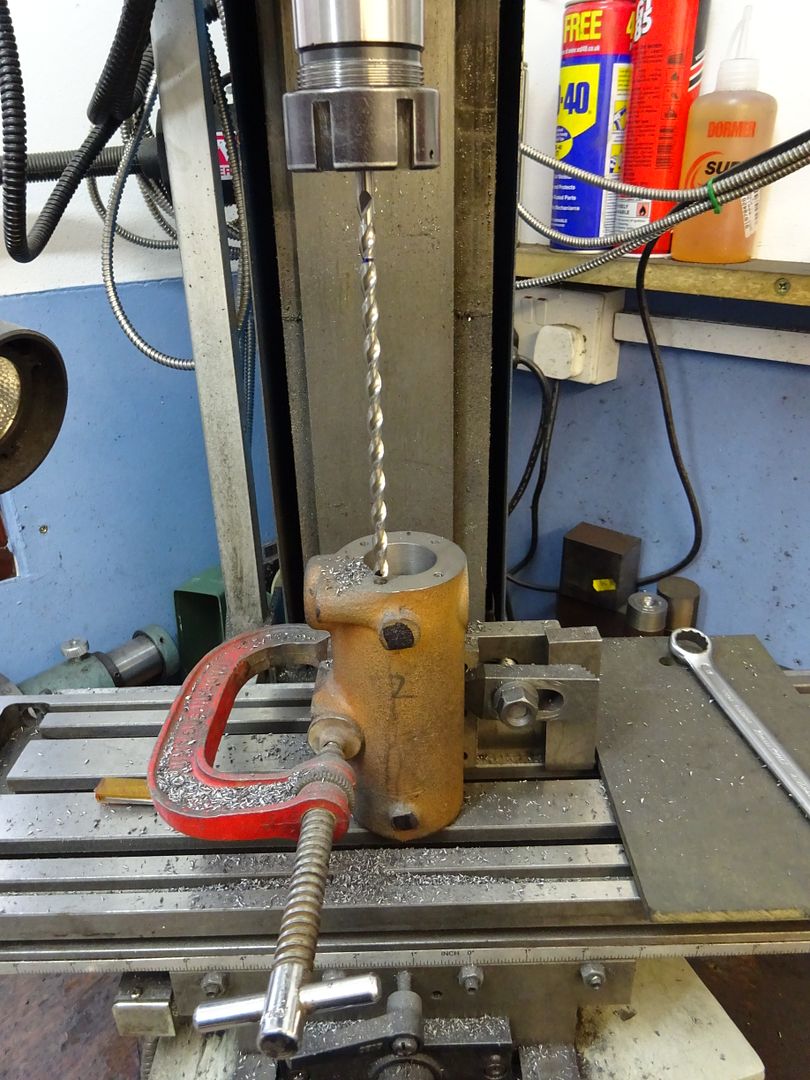

25215 forum posts 3105 photos 1 articles | Easy enough to buy long series and extra long series drill bits, this is a 6mm ELS doing a 135mm long hole in CI.

You don't need to fit the work between ctrs on the lathe, the tailstock can be taken right off to give more length and fix the work to the cross slide then start with a spotting drill, then stub drill, then jobbber, then long series and finally the extra long series. Edited By JasonB on 09/05/2018 19:35:44 |

| Buffer | 09/05/2018 20:03:12 |

| 430 forum posts 171 photos | Jason I have just done a quick search and drills that are too small and too short are crazy prices some over £100. Is there any other way you know of? Thanks Rich

|

| Roderick Jenkins | 09/05/2018 20:04:23 |

2376 forum posts 800 photos | There should't be a problem extending the shank of a HSS drill, they are usually soft. In the past I've tapped a thread in a drill and extended it with a length of steel with a male thread. I've also silver soldered small drills on to extending pieces. With a blacksmiths drill I'd drill a hole in a bar to suit the smaller shank of the drill and use a couple of grub screws to fasten the drill to the extender. I'd file a flat on the blacksmith drill, there will be quite a lot of torque on the screws. If using the pillar drill I'd drill a hole through first with a drill that is slightly larger than the chisel edge of the 20mm drill and then go straight to the larger drill without any more intermediate holes - I think there is less chance of chatter that way. Depending on the lathe, pushing a job against a 20mm drill using the saddle might be a struggle. HTH, Rod |

| Michael Gilligan | 09/05/2018 20:31:25 |

23121 forum posts 1360 photos | Richard, For 20mm diameter, in cast iron, I would look at core-drilling. At its simplest; a length of tube [maybe copper] could be chucked in your pillar drill and abrasive slurry applied. ... It might be slow, but the price is right !! MichaelG.

|

| Clive Brown 1 | 09/05/2018 20:32:07 |

| 1050 forum posts 56 photos | I extended a blacksmith's drill, as suggested by Rod, but istead of grub-screws I cross drilled and pinned the drill and extension together. My reasoning was that, in my case, the wall thicknesss of the extension was rather thin to thread for the grub-screws. |

| JohnF | 09/05/2018 20:39:51 |

1243 forum posts 202 photos | Richard, Roderick is spot on I have extended drills many times by this method, the only thing I would advise is buy a used 20mm HSS drill rather than using a blacksmiths drill, these are invariably carbon steel and not so great. I bought a set some years ago thinking they may be handy but even run slow in MS they don't perform well, OK for none ferrous metals etc though.

|

| Rik Shaw | 09/05/2018 20:55:28 |

1494 forum posts 403 photos | Silver soldering / brazing the required extension using methods suggested on here would be the way to go for me if I came up against your drilling problem. I have always used this method for drilling deep and cannot see a simpler solution. Rik |

| duncan webster | 09/05/2018 21:29:09 |

| 5307 forum posts 83 photos | I've successfully used loctite to attach drill extensions, just don't let it get too hot. Advantage is when you've finished you can warm it up and recover the drill |

| Jeff Dayman | 09/05/2018 22:26:18 |

| 2356 forum posts 47 photos | Hi Richard, At 300 mm depth and 20 mm dia you are in gundrilling territory - depth 15X diameter. Brochure below. No connection to firm apart from being a long term satisfied customer for their gundrills in the mould making industry. https://www.sandvik.coromant.com/sitecollectiondocuments/downloads/global/brochures/en-gb/c-1140-543.pdf A gundrill from these gents or from Guhring would be a top notch tool for the job but three things re DIY- 1. Gundrills are very expensive 2. your pillar drill will not likely have 300 mm depth of vertical feed, probably more like 75 mm vertical feed on many DIY pillar drills 3. your pillar drill may not have sufficient power for gundrilling Rather than buying expensive one time use long drills or gundrills, you might consider going to a local mould making shop for injection moulds and asking them for a quote to drill your hole. Be sure to tell them it's a model engineering job and that you are not in a hurry for it. Chances are they will do a very straight, accurate hole in minimum time, since most mould shops do gundrilling every day for cooling water passages and know all the tricks. You may find the mouldmakers won't charge much to do the job if it is not a rush and you take them a tray of coffees when you pick it up. Just food for thought. Lots of ways to get it done, as others have said. Edited By Jeff Dayman on 09/05/2018 22:28:30 |

| HOWARDT | 09/05/2018 22:44:31 |

| 1081 forum posts 39 photos | You could cut some teeth onto the end of a piece of steel tube and use that as a long core drill. I have used this to hammer a hole through a cavity brick wall, hammer and turn. Obviously here you would need to cool and clear the teeth regularly but taken slow and careful it can be done for almost no cost. Otherwise it's drill with a standard drill through them open out with a core drill to finish. |

| John McNamara | 10/05/2018 00:00:16 |

1377 forum posts 133 photos | Yet again James Virgil Howe to the rescue There is a whole chapter on making gun drills, Regards Edited By John McNamara on 10/05/2018 00:01:27 |

| John Reese | 10/05/2018 00:27:58 |

1071 forum posts | You may be able to find a used 20mm drill with sufficient flute length. You still have a problem because of the limitations of your equipment. The pillar drill will be useless because you don't have enough quill travel to accomplish the job' Drilling on the lathe has potential id you can drill using the carriage. It will be impossible to do in a single pass on hobby size lathes. You could probably do it using a succession of drill sizes. I would start with the largest diameter drill your lathe will handle comfortably. Smaller drills will have more tendency to wander. It would be possible to finish the hole with a D bit but expect problems clearing chips on that deep a hole especially if it is a blind hole. |

| not done it yet | 10/05/2018 05:57:52 |

| 7517 forum posts 20 photos | My first question would be ‘’Why such a large hole through such a depth of material?’’ Poster gives no application details and there may even be alternatives to such a hole...straightness and size control may be issues which need addressing. Personally, I would avoid drilling such a hole, unless specifically required (such as in a gun barrel, for instance). |

| John McNamara | 10/05/2018 06:30:44 |

1377 forum posts 133 photos | This week I had to drill axially centred 1mm x 70mm holes in some cast iron scrap bar. (window weights) It machined easily so all good. Well almost when I drilled it axially the drill wandered a bit maybe 20 thou, something had deflected the drill. hard spot, soft spot, who knows? In this case it was Ok as I was able to machine the outside of the bar after I had drilled it using the hole as a center hole. It was not a super precise job. I had used a normal jobber drill, and it had got the wanders This is where Gun drills differ, they often only have 1 cutting lip the rest of the drill is a solid cylinder several diameters long that has almost no clearance. fully supporting the cutting tip apart from a chip clearing groove. They usually have a cutting oil hole pressure fed to clear the chips, The tight fit in the hole helps keep them straight, think of a gun barrel maybe thirty inches long with a .177" finished hole with little or no straightening required, pretty amazing. Regards

|

| Chris Evans 6 | 10/05/2018 09:10:07 |

2156 forum posts | Plus one for Jeff's gundrilling. I spent my working life in mouldmaking. as a DIY job though we never like spending money so the last time I was faced with a similar job I modified an old long series drill from my building kit of DIY stuff. Namely an SDS drill, cheap to buy and do the job if the hole size / straightness is not an accuracy issue. Certainly better than any brazed on D bit type. The SDS drill shank is soft enough to turn to suit your equipment. |

| Hopper | 10/05/2018 11:02:02 |

7881 forum posts 397 photos | Posted by not done it yet on 10/05/2018 05:57:52:

My first question would be ‘’Why such a large hole through such a depth of material?’’ Poster gives no application details and there may even be alternatives to such a hole...straightness and size control may be issues which need addressing. Personally, I would avoid drilling such a hole, unless specifically required (such as in a gun barrel, for instance). ^^^^^^ This. Any clues as to what the job actually is and why it needs such an unusually long hole in a piece of cast iron? It may well be that the easiest way to drill this awkward hole is to not drill it. There may be alternatives if we knew what we were dealing with.

|

| JasonB | 10/05/2018 11:28:53 |

25215 forum posts 3105 photos 1 articles | Looking back at the subject of Richards few other posts suggests it may be for another cannon barrel. |

| not done it yet | 10/05/2018 12:12:38 |

| 7517 forum posts 20 photos | Yes, but... Is it a blind drilling or through hole? Is it the barrel bore or behind the gun barrel for support? Approaches may be different. |

| JasonB | 10/05/2018 12:37:05 |

25215 forum posts 3105 photos 1 articles | As his next project was going to be a muzzle loader I would hope it's not a through hole. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in