Rotary Table

| BOB BLACKSHAW | 02/04/2018 12:05:20 |

| 501 forum posts 132 photos | I have seen a Rotary Table with dividing plates at a good price, what are the advantages of a Dividing Head over the Rotary Table. I know that a chuck can be fitted to the Rotary Table, it seems to me they do the same job. |

| Bazyle | 02/04/2018 12:22:33 |

6956 forum posts 229 photos | Check the rotab can be mounted on its side or you have a big enough angle plate. Sometimes the extra diameter of the rotab gets in the way but otherwise it is just as capable as a dividing head until you get to the more complex 'universal' type that can tilt and do differential indexing for prime numbers, or be driven to make spirals. |

| john fletcher 1 | 02/04/2018 13:00:53 |

| 893 forum posts | A rotary table is a very useful but not often used device in most workshops, takes up space as well, I know, as I have one together with the dividing plates. Be careful using the tables for gear cutting as there are some with errors and its very annoying to find that you have a thin tooth for no fault of your own. Recently I made a stepper motor Arduino controller from the article in Model Engineer Workshop issue 249 which I can recommend. No more thin or one tooth short errors, works good. The article used two switches as inputs, where as I and I'm sure others have done, used a 4 x 4 key pad. Not being very well versed in micro electronics I received help from readers on this forum, and from my neighbour Steve, many thanks fella's. John |

| Muzzer | 02/04/2018 16:16:36 |

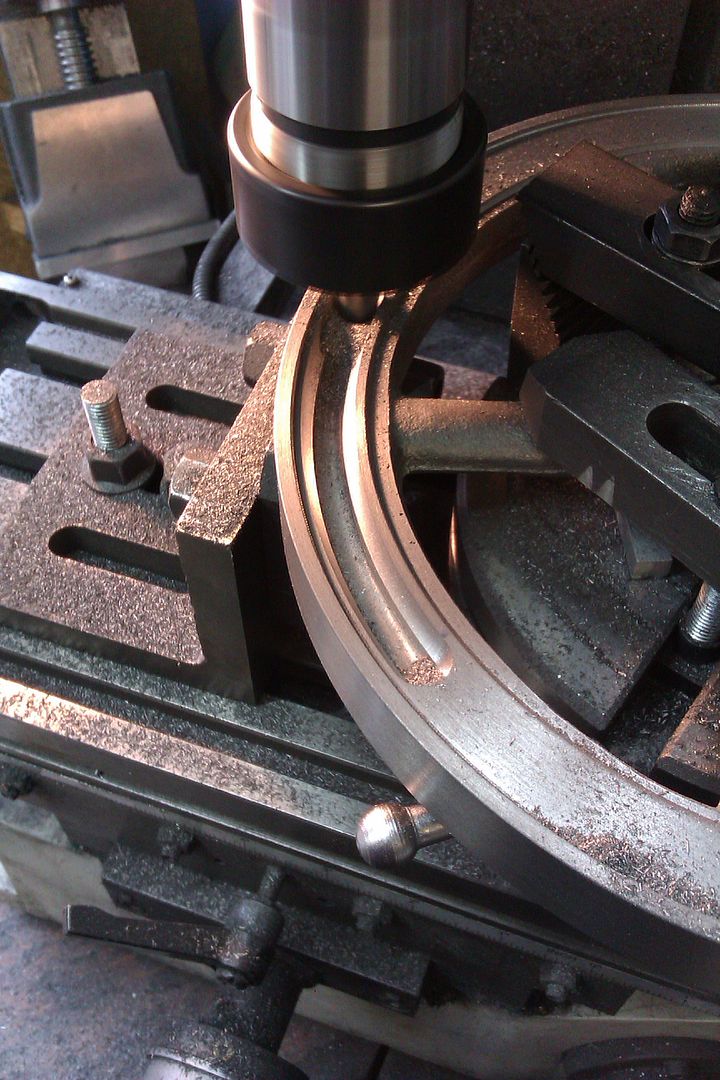

2904 forum posts 448 photos | Unless you have a CNC machine or stepper driven rotary table, a manual rotary table is one of the few ways to machine cylindrical paths in a way you couldn't otherwise. You'd struggle to do that with a dividing head. I used my rotab to machine internal and external surfaces with success, although nowadays my CNC machine does a much better job in a fraction of the time. Murray |

| SillyOldDuffer | 02/04/2018 16:52:21 |

| 10668 forum posts 2415 photos | Posted by BOB BLACKSHAW on 02/04/2018 12:05:20:

I have seen a Rotary Table with dividing plates at a good price, what are the advantages of a Dividing Head over the Rotary Table. I know that a chuck can be fitted to the Rotary Table, it seems to me they do the same job. They are similar devices with similar functionality. But I'd say a Rotary Table is generally more flexible than a Dividing Head. Often a table can be mounted either flat or vertically, whereas heads are typically one-way. It's occasionally useful to be able to clamp work direct to a table. Heads often only divide while tables usually do angles and divisions. Much depends on exactly what you buy: there are some jolly nice Dividing Heads out there. Dave |

| Dave Halford | 02/04/2018 16:57:40 |

| 2536 forum posts 24 photos | Dividing head better for gear cutting and cutting splined shafts. will give you angles assuming your machine is big enough. Rotary table Best used flat so good for drilling circle plates some will mill curves if the gear and worm are up to it and some will strip the threads. OK for any dividing that does not need a tailstock suport |

| richardandtracy | 02/04/2018 18:15:08 |

943 forum posts 10 photos | Rotary table can be used to make dividing plates, not vice versa. I have a rotary table, and combined with a calculator can divide any number of divisions, not limited by the plates. BUT it's even easier to get wrong if not systematic. Regards Richard. |

| Howard Lewis | 02/04/2018 18:26:46 |

| 7227 forum posts 21 photos | I use my Rotary Table in both Horizontal and Vertical mode, which includes cutting gears. But, as said, BEWARE of errors in the division tables supplied with the table. My Vertex HV6 is one such. It cost me three scrap items, before realising that the errors were not mine. I made up my own division table, using EXCEL. This showed that the published table had eight errors or omissions! If you have any doubts about the division tables, take time out and calculate. It may be time well spent! Howard

|

| Neil Wyatt | 02/04/2018 23:16:00 |

19226 forum posts 749 photos 86 articles | As I posted recently, PLEASE see Howard's tables: www.model-engineer.co.uk/news/article/corrected-dividing-tables-for-vertex-hv6-dividing-head/23123 Only today I received a lengthy email prasing them for their accuracy and usefulness. Neil |

| BOB BLACKSHAW | 03/04/2018 02:03:34 |

| 501 forum posts 132 photos | Thanks for these replies they have been very informative. The reply from Dave Halford about cutting curves on the Rotary Table can be a problem with the worm gear, if not up to it. I have been given a 4 inch table some time ago unused which was purchased in the mid eighties. It is a import and will cut a curve in steel as I used this to recess a flywheel. I like the idea of a Rotary Table with plates, the ones I've seen advertised by Warco seem quite a good price, but are they any good,can they cut curves in steel with out stripping the worm gear ? Fed up with buying crap, stuff not fit for purpose until modified. The reply from Richard suggests that I don't need another table, just use a calculator. But would still like one with plates, any recommendations please. Thanks Bob

|

| Paul Lousick | 03/04/2018 04:18:54 |

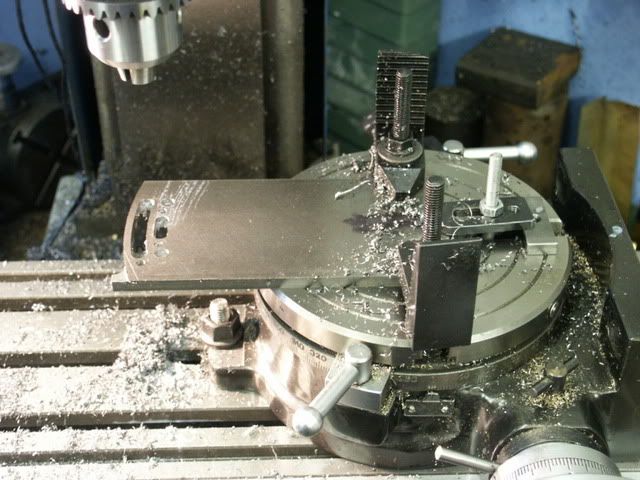

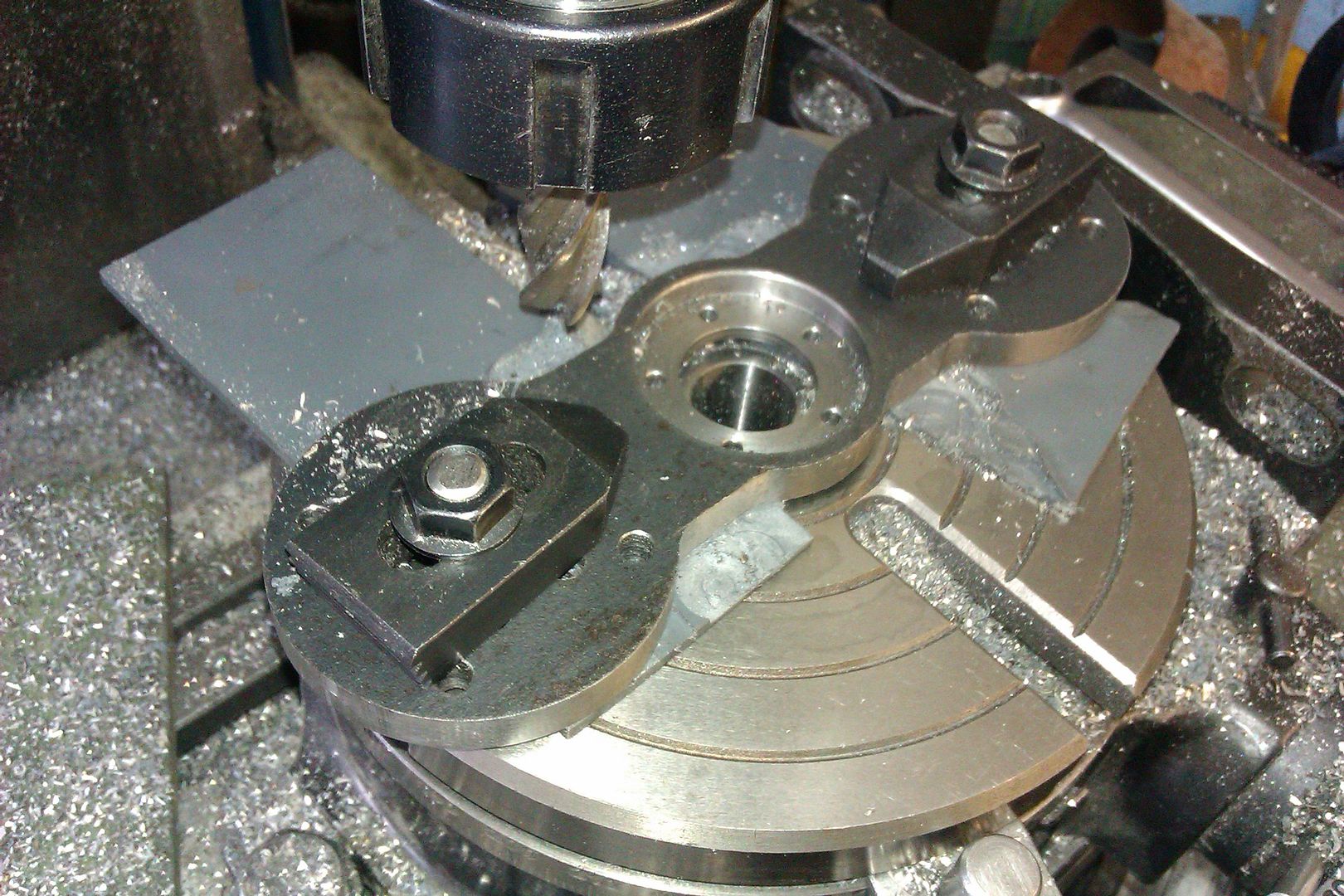

| 2276 forum posts 801 photos | Hi Bob, This is what can happen to the gears when cutting a curve if the load is too high. The rotary table was not one of the cheap ones but a quality one, made in Japan. A rotary table is a handy accessory for your mill for lots of applications.and I would not be without one but would advise that you get the biggest that would fit on your mill table.. Paul. |

| JasonB | 03/04/2018 07:39:38 |

25215 forum posts 3105 photos 1 articles | Posted by BOB BLACKSHAW on 03/04/2018 02:03:34:

, but are they any good,can they cut curves in steel How long is a piece of string? I have happily cut curves in mild steel and gauge plate on my Soba 6" but they were within a reasonable expectation of what the table could handle and the depth of cut was also appropriate to my machine and tooling. Take a look back through some of Paul's other photos and see the size of work being done on his similarly made but "quality labled" table and is it any wonder the gears stripped?

I've been using the 6" one from ARC recently and that is quite nice to use as well, not sure if the gears on that are iron or steel. |

| not done it yet | 03/04/2018 09:09:03 |

| 7517 forum posts 20 photos | Chain drilling followed by light finishing cuts with a keen cutter may be a sensible alternative to trying to make heavy cuts with less than keen cutters (and not climb milling, either), when using a less robustly built rotary table. So, much in agreement with JB, I suppose. |

| Alan Vos | 03/04/2018 19:21:42 |

| 162 forum posts 7 photos | Posted by Howard Lewis on 02/04/2018 18:26:46: If you have any doubts about the division tables, take time out and calculate. It may be time well spent! Apologies to Howard if this is well covered elsewhere, but the calcualation to *check* an entry in a division table is relatively simple. It does involve vulgar fractions. Do schools still teach that? An example I found is that for a 90:1 reduction and 13 divisions you require 6 and 36/39 turns per tooth. (Turns * Divisions) = Reduction (teeth on worm wheel). Those need to match exactly. All integers, No tolerance. No rounding. 13 divisions * 6 whole turns = 78. For the partial turns: 13 * (36/39) = 12. 78 + 12 = 90. |

| larry Phelan | 04/04/2018 11:16:18 |

544 forum posts 17 photos | Whatever about the rotary tables themselves being crap and way out,there is no excuse for the charts to be in error. A simple test run would soon show up any blunders which should then be corrected before production. Too much to hope for ? |

| Howard Lewis | 04/04/2018 17:27:35 |

| 7227 forum posts 21 photos | Without wishing to be rude, it must take some effort to damage the worm and wheel, unless the design spec calls for putty or plasticene! If anyone wants to try amending the original spreadsheet for gear ratios other than the original 90:1, the EXCEL spreadsheet is viewable at the top of the thread quoted by Neil. Hopefully, changing the formula from 90:1 to, say, 40:1 will produce sensible answers for Rotary Table or Dividing head with that ratio. Am wondering if I am clever or brave enough to make two more division plates for my HV6. A "D" plate with 22, 24, 26, 28, 32,34, 38 holes and an "E" plate with 42 and 46 holes. All these should be "doable" with the existing "A", "B" and "C" plates, and would fill a few gaps in the table. Whether or not I would ever use them, is another matter, but "They would come in handy, one day". Another project would be to make a small Dividing Head for the mini lathe, (inspired by Stub Mandrel's one, using the division plates from the HV6. Another "Make it up as you go along job"! Should prevent me getting bored, but not frustrated! Howard |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in