How to make revolving grips for handles?

| Rainbows | 02/03/2018 19:41:42 |

| 658 forum posts 236 photos | Anyone have a method for making cranks for handwheel that rotate in your hand as you turn them? I have a concept where the handle is a tube running over a shoulder bolt but that gives a fairly large minimum diameter and I have to match the length nicely or it would have axial play (not really a practical issue but it would feel more amateurish to use). Off the shelf I can buy them for about £5 upwards but why spend £5 when I can spend £4.50 and 3 hours of my time building one? |

| JasonB | 02/03/2018 19:56:08 |

25215 forum posts 3105 photos 1 articles | I usually make starting handles for the hit and miss engines using a cap head bolt as the spindle. handle is drilled a nice running fit on the plain shank of the bolt and counter bored to take the head. No need for a shoulder bolt if you make the length of the through hole just less that the distance between end of thread and under the head. Screw bolt in until it runs out of thread and there is still a little lengthways play so the handle does not get locked up tight.

J Edited By JasonB on 02/03/2018 19:58:35 |

| Rainbows | 02/03/2018 20:13:47 |

| 658 forum posts 236 photos | Ooh that makes things a fair bit cheaper My other concept which I'm sure I didn't invent was having a ball bearing retain it axially

Down side of course being I have to cross drill and tap the handle. Allows for thinner grips but needs thicker handles |

| Douglas Johnston | 02/03/2018 20:26:29 |

814 forum posts 36 photos | I had to replace that type of handle on my mill a while ago and made a polished stainless steel one that did not revolve. Maybe I have self lubricating hands but it works just as well as a revolving one and a lot simpler to make. As long as the surface is nice and smooth it slides in the hand perfectly fine. |

| Jon | 02/03/2018 20:52:01 |

| 1001 forum posts 49 photos | Nothing amatuerish about using socket shoulder screws you make the part to suit the bolts ordered, what can be easier and professional. Most applications theres no decent thread depth strength using normal Hex head bolts, ending it short against a stop even less so. If thread depths sufficient for the task could locktite bolt down to give desired tolerance on revolving handle, not ideal but ok if its not to be seen or taken apart. |

| Mick B1 | 02/03/2018 21:10:11 |

| 2444 forum posts 139 photos | I make a shoulder screw with a plain diameter a few thou longer than the distance from the bottom of the handle counterbore to its undersurface. Not difficult, and works fine on salt grinders. |

| Mark Rand | 03/03/2018 01:16:02 |

| 1505 forum posts 56 photos | I replaced the handles on my J&S grinder with something similar to JasonB's ones, the bolts were already there, but the handle bits were past their best.

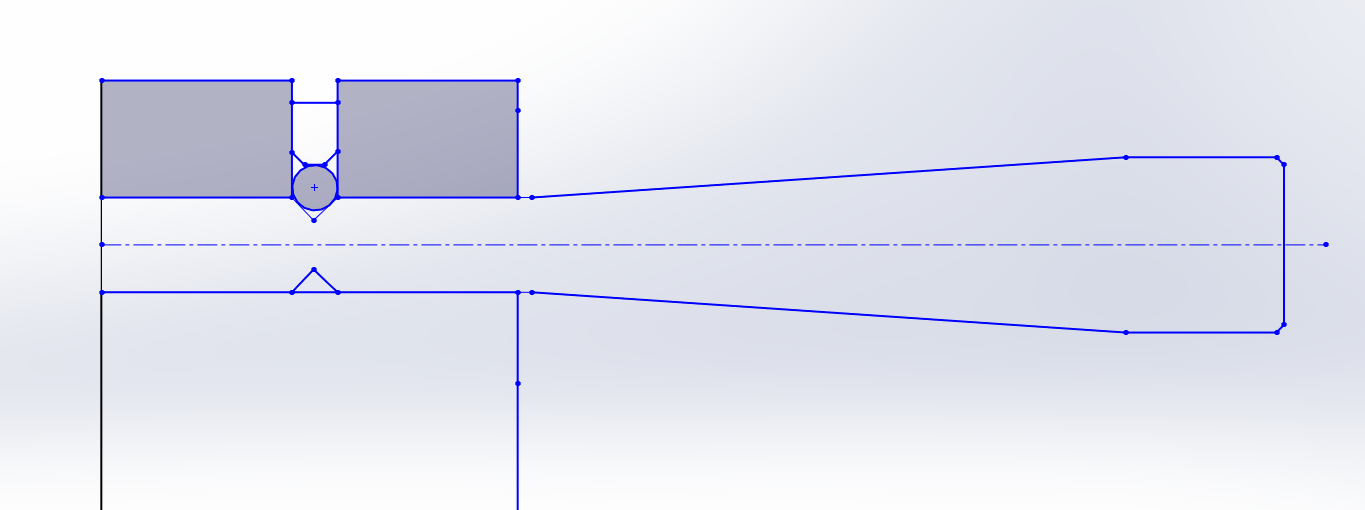

I used black Delrin and turned it to be a close radial and axial fit on the bolts. I made the ends 1/8" longer than needed to clear the bolt heads and turned an internal 7.5° per-side taper in them, with the small bit at the outside. I then turned up plugs with a matching taper and the same dimensions.

Very gentle 70-80°C heating in the oven expanded the handles (on the bolts) to the point where the end caps just popped in with finger pressure.

Being Delrin, they turn smoothly and feel pleasant to the hands. |

| Perko7 | 03/03/2018 01:28:41 |

| 452 forum posts 35 photos | How about adapting the handles from fishing reels? The reels can usually be picked up pretty cheaply at garage sales/car boot sales. They are designed to withstand pretty aggressive conditions so should last a while on a bit of home machinery. |

| thaiguzzi | 03/03/2018 05:31:36 |

704 forum posts 131 photos | Posted by Rainbows on 02/03/2018 19:41:42:

Anyone have a method for making cranks for handwheel that rotate in your hand as you turn them? I have a concept where the handle is a tube running over a shoulder bolt but that gives a fairly large minimum diameter and I have to match the length nicely or it would have axial play (not really a practical issue but it would feel more amateurish to use). Off the shelf I can buy them for about £5 upwards but why spend £5 when I can spend £4.50 and 3 hours of my time building one? Your last paragraph/sentence - i like your way of thinking... |

| Gordon W | 03/03/2018 10:07:13 |

| 2011 forum posts | I made a couple for lathe feedscrew modification. Drilled thru' handle to suit cap head bolt, c/bored for the head, screw into the arm with a drop of thread lock. Just tighten enough, a bit crude maybe but works well. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in