Cutting a fine groove

Where to buy a tool for cutting a narrow groove

| Ian Skeldon 2 | 15/06/2017 19:51:01 |

| 543 forum posts 54 photos | Hi, In one of my latest projects I wish to cut a groove about 1mm deep and about 0.5mm or 0.6mm wide, material will be stainless steel. I am almost resigned to trying to re-grind a HSS parting tool in order to do this. Of course someone out there has probably done this already or knows where a tool that is narrow enough can be bought? Thanks, Ian

|

| JasonB | 15/06/2017 19:57:56 |

25215 forum posts 3105 photos 1 articles | Something like the Mini-thin parting & grooving system would do the job nicely. Tips come in a range of widths in about 0.1mm increments and not too hard to make your own holder if you don't want to buy one. MSC sell them.

|

| not done it yet | 15/06/2017 19:58:52 |

| 7517 forum posts 20 photos | Slitting saw? |

| steamdave | 15/06/2017 20:05:59 |

| 526 forum posts 45 photos | Make a parting tool from an old hacksaw blade if you don't want to buy a special tool. Dave |

| Douglas Johnston | 15/06/2017 20:31:16 |

814 forum posts 36 photos | I bought some of the Mini thin blades a few years ago and found they were very nice for this sort of thing. The downside is the cost and the fact that they are pretty fragile. My ones fractured long ago and would only be replaced if they were cheaper or really needed. |

| Peter Tucker | 15/06/2017 21:04:21 |

| 185 forum posts | Hi Ian, A circlip grooving tool can do that job. Hope this helps. Peter. |

| Ian Skeldon 2 | 15/06/2017 21:09:52 |

| 543 forum posts 54 photos | Thank you, lots of ideas there and a kind offer from John Stevenson. Who are MSC by the way? Thanks again, Ian |

| Robbo | 15/06/2017 22:15:37 |

| 1504 forum posts 142 photos | Google "msc" and this comes up - **LINK** Other search engines are available. |

| Hopper | 16/06/2017 00:21:54 |

7881 forum posts 397 photos | Does nobody grind their own toolbits anymore? A piece of 1/4" or 5/16" or whatever HSS ground down in the shape of a shallow parting tool to the correct width will take you about five minutes to make. You can use a micrometer to measure the width of the toolbit tip so you can get the width to within a thou or so if you so desire. Finishing the last thou or three on an oilstone may help if width is that critical. Shape of the tool is shown below at D, sides have the usual five to ten degrees or so of relief. For grooving you will not need to make the blade so long, so it will be sturdier and easier to grind to such a thin width. Not too hard really.

Edited By Hopper on 16/06/2017 00:27:44 Edited By Hopper on 16/06/2017 00:30:50 |

| Ian Skeldon 2 | 16/06/2017 13:00:51 |

| 543 forum posts 54 photos | Posted by Robbo on 15/06/2017 22:15:37:

Google "msc" and this comes up - **LINK** Other search engines are available. Thanks Robbo |

| Ian Skeldon 2 | 16/06/2017 13:08:40 |

| 543 forum posts 54 photos | Hi Hopper, In years gone by yes I ground many a tool on various grindstones, in fact I was made responsible for dressing them and checking balance, width and dia to make sure they were safe and ready to go or change the wheels if needed. I even went to universal to learn more when they were based in Staffordshire. The reason I don't now is that I have a poxy little bench grinder which would be ok at a push, apart from the useless tool rests, they are so small they are next to useless, and I know what your thinking, why not make better rests. You would be right in that as well, although I am thinking of upgrading to a decent (ish) grinder and then using some angle plate to give me a tool rest that's safe to use and will allow me to produce more of my own tools when required. |

| JasonB | 16/06/2017 13:20:25 |

25215 forum posts 3105 photos 1 articles | I prefer the Mini-thin and find the tips quite durable. I have ground narrow HSS ones in the past but although they may take 5mins to grind the often seemed to snap in 4mins

MSC often do the tips at a reduced rate in their monthly sales flyers which is the time to buy them, they also have a set with holder and about 5 tips at a good price too that regularly crops up. Edited By JasonB on 16/06/2017 13:22:08 |

| Neil Wyatt | 16/06/2017 23:00:27 |

19226 forum posts 749 photos 86 articles | I ground a short 1mm wide tip on the end of wider parting tool. Neil |

| Nige | 25/06/2017 08:07:11 |

370 forum posts 65 photos | Last night I was sorting through a load of old taps and dies I inherited along with the ML4 and wondered if taps that had seen better days could be ground to serve as lathe tools for occasions such as Ian Skeldon 2 is enquiring? I know the taps are 'hard' as they are HSS but seem to remember that they are also 'brittle' and wonder if this precludes their use as lathe cutting tools? The smallest taps and dies I found in the stuff I sorted out are 12 BA ! 😳 Nige |

| IanT | 25/06/2017 09:26:07 |

| 2147 forum posts 222 photos | My 'groover' is a bit of Junior hacksaw blade, held in a special tool holder I made (very quickly) by first slitting a length of square mild steel (to take the piece of blade) - then turning that end round before clamping the blade with a collar and grub screw that fits over the turned end. Hope that's clear but I'll post a photo if anyone Is particularly interested. Costs virtually nothing to make and works well on small brass & mild steel parts (not tried it on stainless). Needs a bit of side room from the chuck and I've meant to make a Mason form of blade holder but not got round to it yet as this as been OK for my needs thus far.... Regards, IanT |

| Russell Eberhardt | 25/06/2017 11:08:45 |

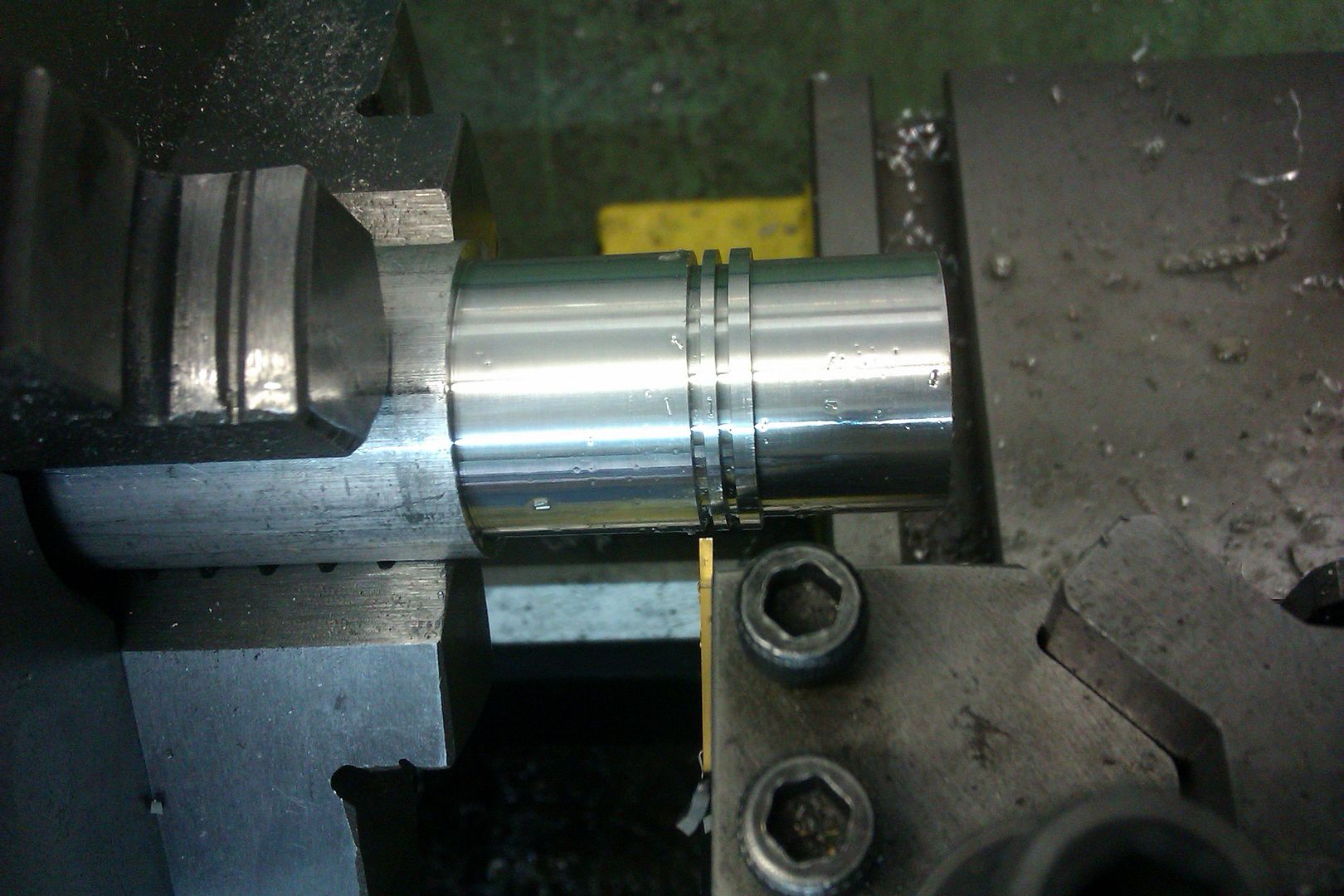

2785 forum posts 87 photos | Posted by Hopper on 16/06/2017 00:21:54:

Does nobody grind their own toolbits anymore? Yes, here's one I made earlier. A 1 mm parting tool for parting a number of parts off 1/8 in silver steel. I've also made a holder for 1/8 round HSS or silver steel toolbits. The latter can be made very quickly by filing before hardening and finish grinding. The round bits are very good for threading as they can be rotated to suit the helix angle - not my idea G. H. Thomas' idea. Russell Edited By Russell Eberhardt on 25/06/2017 11:09:29 |

| ega | 25/06/2017 11:21:04 |

| 2805 forum posts 219 photos | Ian T: "My 'groover' is a bit of Junior hacksaw blade" This interested me as I have always thought the Junior blades were made from old tobacco tin lids! This clearly works for you, of course, and I may give it a try. The Junior blades do seem to be a few thou thinner than a conventional 12" hacksaw blade and a good deal thinner than standard parting blades. Given that it seems necessary to grind the teeth off the blade an all hard type would appear to be a better bet. |

| Ian Skeldon 2 | 25/06/2017 17:18:26 |

| 543 forum posts 54 photos | I decided to try a few trial attempts before committing to the required end product. The hack saw blade attempts were not very good, but to be honest I will try again with a better quality hacksaw blade. Grinding an old HSS tool is almost there, but the tool still needs to lose another 0.3 or 0.4 mm in width in order to produce the result I need. I did manage to get one groove that is satisfactory, I used a very thin carborundum disc from a set intended for a dremel drill, it took for ever but did eventually manage it. It has made me think about using a mini drill somehow secured in the tool post and then grinding the groove, I will let you know if I do try this and of if it works. Mean time thanks for all the suggestions. |

| Russell Eberhardt | 25/06/2017 19:19:37 |

2785 forum posts 87 photos | Posted by Ian Skeldon 2 on 25/06/2017 17:18:26:

I decided to try a few trial attempts before committing to the required end product. The hack saw blade attempts were not very good, but to be honest I will try again with a better quality hacksaw blade. I made a holder for broken bits of HSS hacksaw blades about 20 years ago and still find use for it occasionally. The 12" x ½" blades are about 0.7 mm thick so will still need to be thinned down a little. Russell |

| Ian Skeldon 2 | 25/06/2017 20:23:28 |

| 543 forum posts 54 photos | Trying the hacksaw blades has made me realise how poor our general quality of simple tools and engineering supplies have become. As an apprentice (many, many years ago) hacksaw blades were very hard and of course that made them brittle, but they never bent, twisted or deformed like the stuff you get now, and they lasted well, ah well reminiscing over. Thanks Russell, I'll try to source some dearer, better quality ones and have a go with one. Ian |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in