Keyway cutting

How to cut a keyway

| Malcolm Begg | 02/05/2017 22:30:22 |

| 15 forum posts 4 photos | Any good easy ideas for cutting an inner and outer slot for a keyway? |

| Brian H | 02/05/2017 22:57:47 |

2312 forum posts 112 photos | What size keyways and what size hole & shaft?? Brian |

| IanT | 02/05/2017 23:50:22 |

| 2147 forum posts 222 photos | The quick (and silly) answer Malcolm is a shaper - but if you had one available, then you would have known that already. Obviously, external slots can be milled (or flycut) in a lathe or mill. However, internal slots need some form of linear cutting tool - in industry a slotter or shaper - which essentially move a cutting tool in and out of the bore to cut the slot. This can be done on the lathe with a tool held in a boring bar mounted on the cross-slide and by racking the saddle too and fro to make the cut. Not ideal but it does work. There have also been several designs published for slotting tools that fit on the cross-slide that make things easier. Hope this helps. Regards,

IanT Edited By IanT on 02/05/2017 23:51:40 |

| Hopper | 03/05/2017 00:00:17 |

7881 forum posts 397 photos | YOu can hold the shaft in the toolpost at the right height, the end mill cutter in the lathe chuck and machine it that way. Then do the internal as described above, using the lathe as an impromptu shaper or slot cutter. |

| Dsel | 03/05/2017 00:33:34 |

| 45 forum posts 34 photos |

|

| John Olsen | 03/05/2017 03:20:30 |

| 1294 forum posts 108 photos 1 articles | I'm sure we have discussed this before...but anyway, assuming you don't happen to have a slotter or a shaper lying around, make a plug of the same sort of material to just fit the hole. Loctite it in, flush at one end. Make a centre pop mark on the line where the two materials join just where you want the keyway. In the drill press, drill a hole just under the size that the keyway is supposed to be. Knock the plug out, using heat if necessary, and now you have about 75% of your keyway done. With a suitable file, file out the corners to make it square, trying the key frequently until you have a good fit. You can do them on a shaper, and since I have three shapers I have done this, but if you only have one or two to do it is faster to do them by hand as described above, since otherwise you have to mess around making up the right tooling for the shaper. For the shaft, a slot drill as described earlier is good, but otherwise they can be done by hand too. You drill a hole at each end and then chisel out the material between with a small cold chisel. The old millwrights did a lot of them this way, since the shafts were often not readily removable to take to a machine. John |

| not done it yet | 03/05/2017 07:58:10 |

| 7517 forum posts 20 photos | Buy or make a broach? |

| Malcolm Begg | 03/05/2017 22:39:12 |

| 15 forum posts 4 photos | Thanks for your suggestions Malcolm |

| Clive Foster | 03/05/2017 23:40:03 |

| 3630 forum posts 128 photos | Dunno if you have the proper sizes to hand but working to a measured dimension is much easier than sneaking up by cut'n try. This link gives imperial sizes :- **LINK** and this one metric sizes :- **LINK**. With a bit of care and accurate drilling you can arrange matters to leave very little metal in the hub to be filed or slotted out. A CAD program is a great help when sorting out exactly what size drill to use and where to put it. If you plan to file and have a suitable size piece of tool steel its worth arranging a single tooth fixed depth broach on a round bar made a nice sliding fit in the bore. Only good for a couple of thou each side but will clean up the slot really nicely. Milling is by far the best way to put the slot in the shaft. Quite easy with the dimensions to hand. Clive.

|

| Colin LLoyd | 25/01/2019 11:11:25 |

211 forum posts 18 photos | I'm interested in general regarding cutting internal keyways, but not sufficient to buy a set of broaches for my occasional use. But I saw this video ( https://www.youtube.com/watch?v=XcU0LTavzDM ) where a single cutter held in a lathe toolpost is fed into the component held in a stationary lathe chuck, with the cross-slide and saddle being used to make the lengthwise and depth cutting. I'm guessing this is what IanT alluded to above. IanT also alluded to DIY designs for this tool - does anybody have diagrams for such a tool? |

| Paul Lousick | 25/01/2019 11:53:03 |

| 2276 forum posts 801 photos | There is no need to buy a set of broaches, only the size that you need and make your own guide bushes. 3mm keyway broaches are available from $29 on ebay, 6mm for $43. I have a couple and good enough for hobby work. Larger sizes get more expensive. You will need a lathe for makinging the bush, milling facilities for cutting slot in bush and shaft and a means of pressing the broach thru the bush. (before I had a hyd press, I used a drill press to push thru a 3mm slot) Paul. |

| Colin LLoyd | 25/01/2019 12:09:26 |

211 forum posts 18 photos | Thanks Paul - even at that price (and it is higher in the UK) it's still greater than I would like to pay for something that I might never use. However, the ability to grind my own HSS tool to suit - if the need arises - appeals to me. And as I have both lathe and milling machine - the machining aspects are not difficult. I just need some idea of cutting angles for the HSS tool. I could even regrind a parting tool to provide the pushed cutting edge - after all the video shows the tool acting just like a wood plane does. It may take longer than broaches - but I have the time and the items I envisage I might need to keyway will be small and one-offs. |

| Brian G | 25/01/2019 12:26:48 |

| 912 forum posts 40 photos | You could perhaps save time (edit: and the strain on the lathe) by starting the keyway with a small slot drill so that you only have to remove the corners from a D shaped slot? Brian Edited By Brian G on 25/01/2019 12:27:12 |

| Les Jones 1 | 25/01/2019 12:27:30 |

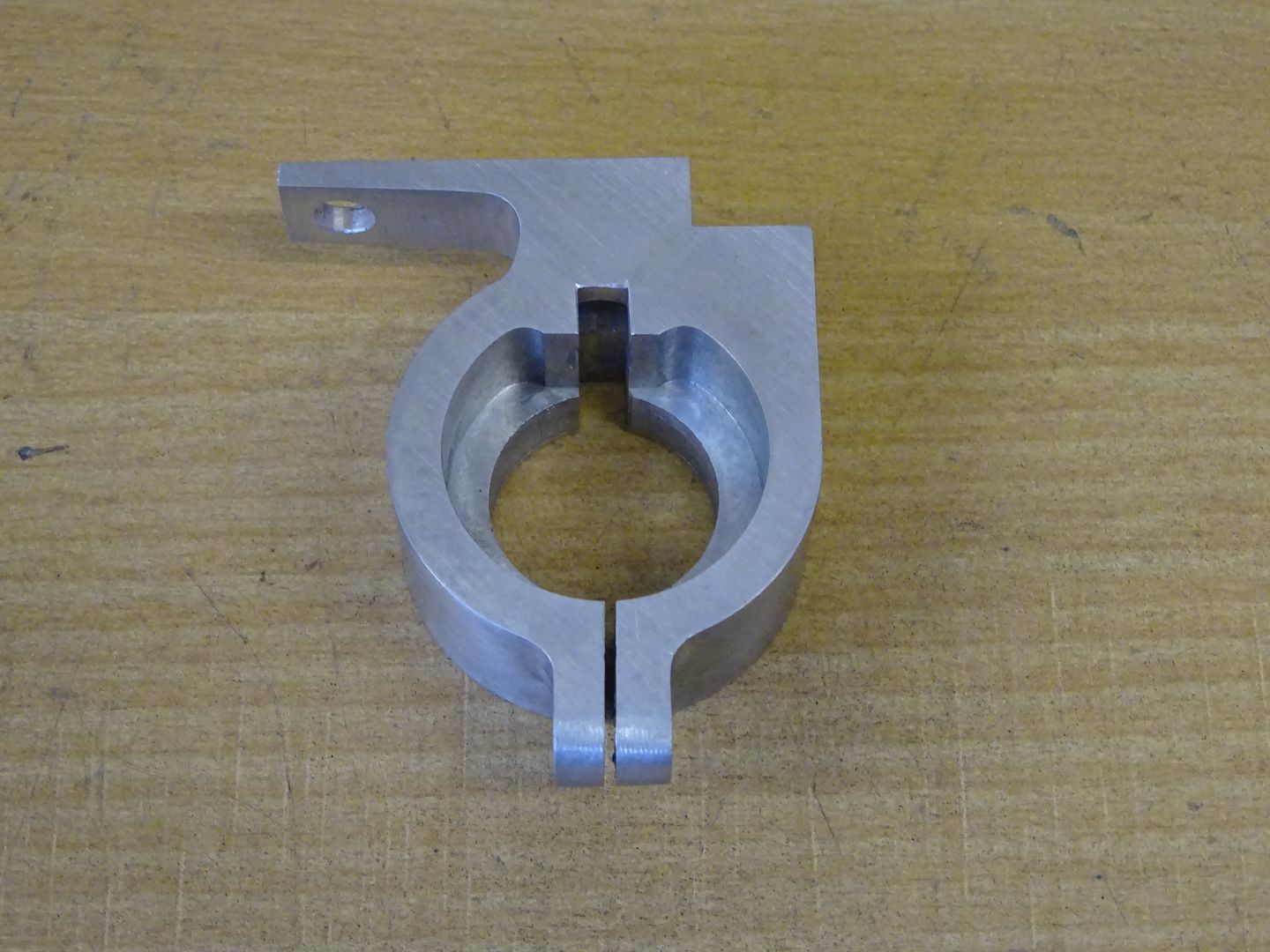

| 2292 forum posts 159 photos | This is a very crude thing I made to move the saddle backwards and forwards for slot cutting in the lathe. It avoids putting too much load on the rack and pinion. The lever pivot part is clamped to the lathe bed with blocks of wood and lengths of threaded rod. Les. |

| Micky T | 25/01/2019 12:37:13 |

76 forum posts 29 photos | If you have access to the archives there was a plan for a slotting attachment in issue 6 August/September 1991 which would meet your requirements Mickyt |

| Michael Cox 1 | 25/01/2019 12:41:31 |

| 555 forum posts 27 photos | Here are the things I have made to do internal keyways: http://mikesworkshop.weebly.com/toolpost-slotting-tool.html http://mikesworkshop.weebly.com/small-hole-slotting-tool.html Mike |

| JasonB | 25/01/2019 13:05:04 |

25215 forum posts 3105 photos 1 articles | No need to waste your time and materials knocking up special tools just a suitably sized HSS toolbit in your toolpost will do. Or if you want a boring bar with a tool mounted on it's side.

Edited By JasonB on 25/01/2019 13:05:57 |

| HOWARDT | 25/01/2019 14:22:45 |

| 1081 forum posts 39 photos | Needed to do a couple of keyways in some new drive pulleys for my mini lathe. Milled the slots under size then filed them to fit. Depth is not critical and width can be controlled with a small file easily enough. Both now fitted and lathe back working. |

| mechman48 | 25/01/2019 15:30:39 |

2947 forum posts 468 photos | … 'For the shaft, a slot drill as described earlier is good, but otherwise they can be done by hand too. You drill a hole at each end and then chisel out the material between with a small cold chisel. The old millwrights did a lot of them this way, since the shafts were often not readily removable to take to a machine'. John |

| Colin LLoyd | 25/01/2019 16:06:56 |

211 forum posts 18 photos | Thanks to everyone - the drill out with a slot drill to ease the strain on the lathe is good idea. I will also investigate the archives and follow up Michael Cox and JasonB suggestions. I think this is all I need to know to start to practice keyway cutting - thanks to everyone again. Will suggest that my input to this thread is now answered. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in