Pre-load of taper-rollers

| Tim Stevens | 01/05/2017 16:49:15 |

1779 forum posts 1 photos | Following the collapse of several old-fashioned bearings in my 1928 Lea Francis car axle, I have re-made the pinion housing for the diff with tapered roller bearings. The original light-alloy housing has been machined out to take steel sleeves each end, and the bearings are fitted in the sleeves. Now, I know that such bearings work best (and last longer) if there is a pre-load on assembly, set by the exact length of the spacer-tube, and I have made the assembly so that the tube is easy to remove for final machining etc. But - how much pre-load? I can measure it by checking the torque required to spin the pinion in the assembly, before fitting the oil seal. But the question remains - how much torque is correct? The bearings are both 2" x 1" and about 3.5" apart. I have tried various in hand car manuals for a guide, but none of them is detailed enough. You know the drill - assembly is the reverse of dismantling; using a suitable tool - that sort of thing. Any ideas, anyone? Regards, Tim |

| Nigel Bennett | 01/05/2017 17:12:34 |

500 forum posts 31 photos | A tiny difference in the length of your spacer tube will make huge differences to the amount of preload on your bearings. We're talking tenths of thous here. Ideally you should have some kind of adjustment (think lathe spindle bearing adjustments) and be able to lock it all up once you've got the preload you want. It's usual to specify some kind of torque value when the bearings are adjusted correctly - on my Boxford 280, for example, you wrap some string around the spindle nose and measure the load needed to rotate the spindle, which should be of the order of one pound. I think you will be in for a lot of mantling and dismantling to skim bits off your sleeve if you go that route, and if the bearings then take up a bit in their housings, you'll have a sloppy assembly and all the weary work to repeat but with a longer sleeve... hence the adjustable bit is a better idea if it's at all possible. With regard to your original question about how much preload, Timken or SKF websites should give you a clue. Good luck! |

| Tim Stevens | 01/05/2017 17:27:12 |

1779 forum posts 1 photos | I have looked at the SKF site and it gives a long explanation of why, and what makes a difference, but gives no clue about the actual figures to expect in the real world. The problem with an adjustable sleeve is that the assembly, once fitted to the car, is quite complex to remove and impossible of access in place - so it isn't going to get done. The original which failed had an adjustable sleeve but with a pair of ball thrust bearings. The adjustment was still tight, incidentally, but there was over a quarter of an inch of 'float' axially when we stopped at the roadside. And one set of balls, the cage, and the end cover were either lost down the road or ground up in the oil. Jolly fun. So, whatever the magic figure is, it is going to be 'fit and ignore' - like the last version which has lasted for 80 years or so. Cheers, Tim |

| Martin W | 01/05/2017 17:27:40 |

| 940 forum posts 30 photos | Tim Don't know if this or this is of any use to you, I have found some other references from manufacturers but it seemed far to vague with no figures etc. Martin W PS This might be worth a read as well as it describes various methods of applying preload. Edited By Martin W on 01/05/2017 17:36:04 Edited By Martin W on 01/05/2017 17:59:38 |

| Joseph Noci 1 | 01/05/2017 18:55:40 |

| 1323 forum posts 1431 photos | Taper Pre-load is an interesting issue. I have no answer for you Tim, only can add my questions! Nigel, the pre-load method you describe for your Boxford - is that out of the handbook? I have long sought the method for my EMCO Maximat V10P, and there does not seem to be a Factory Definitive method in any of their handbooks. There are many 'experts' who swear by a method that they specify, but all seem to smell of some or other snake oil, and the resulting pre-load varies accordingly! ...The FAG data manuals ( the V10 Bearings are FAG) give a range of preload, but do not break it down to applications, eg, wheel bearing application, lathe spindle, etc, and the range they give varies by more than 300 percent in load, as they say 'depending on application'! I would have thought that this process should be 'simple' engineering science, and not imaginative application of a bigger spanner... Strange.. regards Joe |

| JA | 01/05/2017 19:21:11 |

1605 forum posts 83 photos | I will follow this thread with interest since this is something I have never quite understood. Obviously a small amount of preload makes sense but the only two uses of taper roller bearings I know of do not make sense. Velocette on some of their singles preloaded the taper roller main bearings quite a bit. From memory the handbook gave a figure for the gap between crankcase faces prior to doing up the crankcase bolts. I always felt that this was a desperate attempt the stiffen the assembly when the crankcases were quite flexible. AJS and Matchless used taper roller wheel bearings from about 1930 to 1963. These were assembled with end play (no preload). According to the handbook there should have been about 0.002" side rock at the wheel rim. This used to give problems with over enthusiastic MOT tests. I feel that, in general, their use shows a level of desperation, usually the lack of space to fit cheaper roller or ball bearings. JA JA |

| Michael Gilligan | 01/05/2017 19:33:55 |

23121 forum posts 1360 photos | For what it's worth, Tim ... [reading across from wheel bearings] ... MOT testers generally expect to feel slight play at the rim of the wheel [this is to allow a safety margin for tightening-up with variations in temperature] ... something in the order of 1mm t.i.r. Perhaps you could extrapolate [backwards] from that [?] MichaelG. . Edit: ... interesting to see JA's very different figure !! Edited By Michael Gilligan on 01/05/2017 19:36:08 |

| Nigel McBurney 1 | 01/05/2017 19:43:59 |

1101 forum posts 3 photos | pre load must vary with the application,surely when the car is in use the alaluminium axle housing will warm up and expand and I would assume expansion would increase preload,so it may be advisable not to have too much or if any preload when cold, The MOT examiner picked up slack front wheel taper bearings on a Morris Ital I then showed him the handbook and when cold they were really slack,i thought this deliberate slackness was probably to allow for hub expansion with heat from the disc brakes, Is there a lea francis owners club ,they may have the info,If i did not have the preload information ,I would set up with minimum or no preload ,rather than too tight and further tightening due to expansion could wreck the bearings.And its no good looking at other cars as the vast majority had ferrous housings with less expansion. |

| duncan webster | 01/05/2017 19:50:17 |

| 5307 forum posts 83 photos | I'd give SKF or Timken a ring, they are very helpful, even for oddball applicatons like this. I supect that they add a bit of interest to their lives! |

| Tim Stevens | 01/05/2017 20:10:42 |

1779 forum posts 1 photos | I have discovered a helpful comment in - of all things - a text book. Advanced Vehicle Technology, by Heintz Heisler: 'Gradually tighten the nut to the correct torque (about 100-130Nm). Rotate the pinion several times so that the bearings settle to their running conditions and then check the pre-load resistance using the preload gauge attached to the pinion nut or drive flange. Typical pre-load torque ranges from 15 - 25Nm. If necessary increase or decrease the spacer thickness to keep within the specified pre-load. Note that 0.05 shim thickness is approximately equal to 0.9Nm pre-load torque.' What a gent - thanks, Heintz, my ole mate. Cheers, Tim PS regarding expansion - the housing in my example is about half old light alloy and half new steel - so I don't think it will make enough difference to worry about. And in any case, as the figure is a guess (based on my set up only being vaguely similar to the one Heintz had in mind) any variation from expansion is just as likely to be an improvement as not. Tim Edited By Tim Stevens on 01/05/2017 20:13:48 |

| Russell Eberhardt | 01/05/2017 20:23:11 |

2785 forum posts 87 photos | Reading my 1920s edition of "The Modern Motor Engineer" there is a short section on Timken rear axles. These, of course, used a pair of Timken roller bearings. The recommendation from Timken was to: "tighten the adjusting nut D untill the shaft will turn freely but with only slight end play. The latter should be about 5/1000 in., after tightening the lock-nut" So, no pre-load at all. It's not a precision machine tool! As far as problems with differential expansion due to the rear axle heating up are concerned I would ignore it considering the level of power typically being put through a substantial 1920s rear axle. Russell. |

| Nigel Bennett | 01/05/2017 20:34:56 |

500 forum posts 31 photos | Joseph, the Boxford manual says "Pre-load condition may be checked using the cord and spring balance method, when a steady pull in the region of 0,68kg (1.5lb) for new bearings or 0,34kg (0.75lb) for used bearings should be obtained, with the cord wrapped round the spindle nose and all gearing disengaged from the spindle." Tests must be undertaken at room temperature. |

| John Rudd | 01/05/2017 21:27:39 |

| 1479 forum posts 1 photos | The result of overtightening a taper roller is pretty grim.... Can result in the inner race becoming 'welded' to the parent shaft...... I know this from personal experience of a mk3 Cortina front stub axle.... Edited By John Rudd on 01/05/2017 21:28:17 |

| Chris Evans 6 | 01/05/2017 21:44:02 |

2156 forum posts | Can't help with the pre load but happy memories from when I ran a "Leaf" (1929). I would just go by what feels right when you spanner it up. |

| Waggonerman | 01/05/2017 22:05:47 |

| 12 forum posts 5 photos |

Hello all, From my experience of rebuilding industrial machine gearboxes & drives, preloading of bearings was only undertaken when precise running tolerances were required with zero runout this at a cost of increased friction, heat, wear & a shorter overall life, typically these bearing were set-up with between .0005" - .001" axial freedom ('dry' with bearings centred) once lubrcation was introduced either grease or oil then the resultant oil film reduced the free play to roughly zero, if I remember correctly older type car wheel bearings were tightened until the bearings started binding then the nut was backed- off one split pin slot. Just my contribution to the debate.

|

| Nimble | 02/05/2017 02:35:49 |

66 forum posts 6 photos | When I overhauled the differential on my 1926 Renault I used the following information from my Triumph Herald workshop manual for guidance. Assemble the pinion with the bearings, spacer and driving flange and tighten the flange nut gradually to the correct torque of 70ft/lbs (9.678 m.k.g.)while constantly rotating the drive flange to ensure that the bearing do not become overloaded during the process, if necessary remove the flange and insert more shim washers. When correctly tightened a preload torque of 12-16 lbs/in should be required to rotate the assembly (16lbs/ in for new bearings). Note that .001” shim thickness makes a difference of approx 4 lbs/in. A counterbalanced beam with a sliding counterweight that clips into the flange driving (Churchill special tool No. S98A) is used. I had to use a cord wrapped around a round drum and a spring balance to achieve the necessary reading. |

| warwick wilton 1 | 02/05/2017 06:12:22 |

| 17 forum posts 2 photos | Hi Tim some of the modern vehicles use crush bushers to set the preload as one of the diff rebuilder told me that he reuses them by putting in a ten thou shim so as not to by a new one. you may be able to find one that will fit? Warwick |

| clogs | 02/05/2017 06:50:15 |

| 630 forum posts 12 photos | Tim, this will be prob to late for you but.......when apprenticed a v/large Ford main dealer's 40 odd years ago we used to repair/overhaul the diff's from the complete range of model's......I cannot remember the numbers/preload values but in all cases we used (gen Ford part) a thin walled tube as a spacer between the bearings.......the nut a 1" ish all metal locking nut was used to set the preload....the tube was crushed/deformed and everything held in place by the Self locking nut... The new oil seal was already fitted, Fords allowed for the oil seal drag in the spec's..... There was no specific torque value on the nut although over time we worked it out to get the lower pre-load limit to speed up the job, the preload was measured using a long bar with a measured scale and a weight locked to the bar with a thumb screw bolt ....giving lbs ft---hence drag/pre load........ this bar was bolted to the front flange of the diff with a plate, a hole in the plates centre was big enough for the socket and an additional couple of pins was used so as to attach a locking bar making it possible to tighten the locknut without taking the weight bar off.....turning the whole pinion shaft assy (weight bar as well) a few times (after tightening the nut, EVERYTIME) to settle the bearings in..... Normally this took about 5-10mins to set up with practice.......remember if u got the preload too tight it was nec to strip it out and replace the tube.........then of course u need to start the whole process again....... REMEMBERING, at no time can you loosen the nut......if you need to loosen the nut the crush tube will need to be changed.........sounds difficult but it was a very easy job to do...... hope this may help.....this idea would/should be quite adaptable and Ford used this method on millions of cars....Clogs |

| Chris Evans 6 | 02/05/2017 07:38:00 |

2156 forum posts | The spring balance idea is a bit like setting up the swivels on an old Land Rover. They use a lower taper bearing and a "Railco" bush for the top king pin. Shims played around with until about 10 pound pull on the steering arm. |

| Hopper | 02/05/2017 08:55:52 |

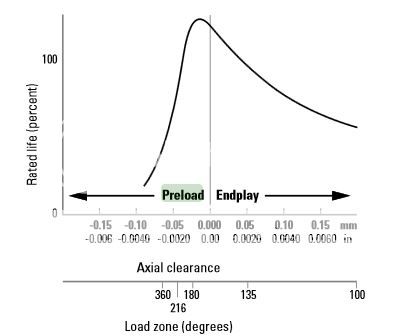

7881 forum posts 397 photos | Best to err on the side of too loose than too tight, or damage will result. Been doing motorbike taper roller wheelbearings for years by setting them as no perceptible drag at the rim with no perceptible shake at the rim, ie neutral pre-load. As the below chart shows, you really don't want more than one thou preload at the most.

BMW factory manual for the old 1970s models used to specify a slight preload, measured with a spring scale and a piece of string wrapped around the axle and spacers tightened up to simulate working conditions. But I don't know anyone who ever actually did this. On the other hand, Harley Dangerous specify .002" clearance in their tapered wheel bearings, which I feel amounts to too much movement at the rim. Hence the method in the above paragraph. Never had a problem with a fixed sleeve adjustment. Just machine a tad off as required, or add a shim as required. The easy way is to make one spacer sleeve about 1/8" too short, then a selection of "wedding rings" about 1/8" long but with the exact lengths varying in one thou incrments. So instead of machining the main sleeve to length, you just swap and change the wedding rings until you get the one that feels right. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in