Olympic Class liners - building the engines

| JasonB | 30/01/2017 18:37:45 |

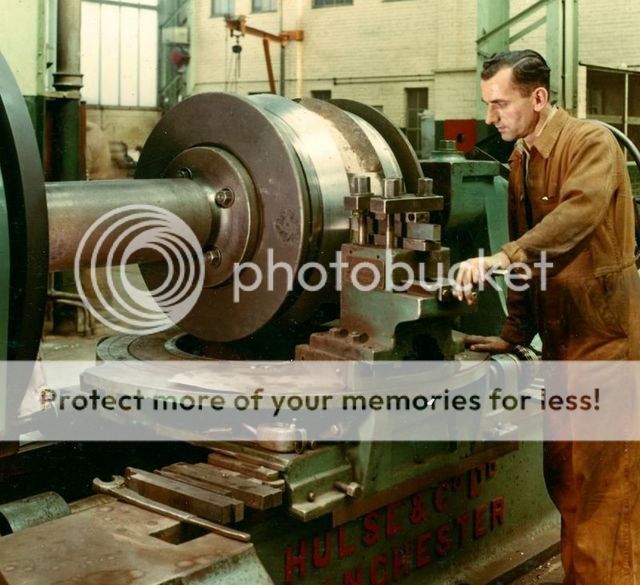

25215 forum posts 3105 photos 1 articles | This was on another forum today and I thought the photos may be of interest to some here, big boy engineering of the engines for Titanic etc.

J |

| Andrew Johnston | 30/01/2017 19:07:17 |

7061 forum posts 719 photos | It counts as a big lathe if you need a set of steps to reach the toolpost. Andrew |

| JasonB | 30/01/2017 19:16:18 |

25215 forum posts 3105 photos 1 articles | Did you notice the zig-zag herring bone gears in one of the photos Andrew? You have not tried one of those yet |

| Phil Stevenson | 30/01/2017 19:18:11 |

| 90 forum posts 13 photos | Jason, thank you so much for posting this. My grandfather was a turner at Harland and Wolff and worked on the Titanic, and probably her sister ships. I have very clear memories of him trying to get me as a small boy to understand the size of the pistons he worked on; he also told me of the news coming through of the sinking. No-one believed the story for some time, such was their faith in the ship. His voice was still full of emotion half a century after the tragedy. I have one or two of his tools, almost certainly from his time as H&W as he worked their all his life. I'll study the pictures in some detail - might even spot someone I know! Thanks again - very special pictures for me. |

| duncan webster | 30/01/2017 20:16:19 |

| 5307 forum posts 83 photos | Posted by Andrew Johnston on 30/01/2017 19:07:17:

It counts as a big lathe if you need a set of steps to reach the toolpost. Andrew It's only big if there is a chair for the operator fastened to the toolpost so he can ride along with it! I think it was GEC who had a monster lathe with a headstock at each end and 2 saddles. Whether you could drop a tailstock (or 2) in the middle and use it as 2 independant lathes I'm not sure |

| Roger Williams 2 | 30/01/2017 20:31:31 |

| 368 forum posts 7 photos | Fantastic pictures !. I think Harland and Wolff are still going, doing oil rig wotk. |

| Brian H | 30/01/2017 20:41:21 |

2312 forum posts 112 photos | I used to work at a company called Crossley-Premier Engines and they had a large lathe with steps up to the toolpost and also a chair from which the operator could control everything.

They also had a strange crankshaft finishing machine where the crankshaft was clamped to tables and the tool was in a holder that revolved around the journal! |

| Nick_G | 30/01/2017 22:01:55 |

1808 forum posts 744 photos | . Fantastic. Nick |

| Scrumpy | 30/01/2017 22:11:19 |

152 forum posts | What skills these people have no DRO or CNC in sight just outstanding tradesman, it makes one feel proud , when we led the world in heavy engineering |

| "Bill Hancox" | 30/01/2017 22:13:03 |

257 forum posts 77 photos | Posted by JasonB on 30/01/2017 18:37:45:

This was on another forum today and I thought the photos may be of interest to some here, big boy engineering of the engines for Titanic etc. Excellent post Jason. I love this sort of pictorial engineering history. The photography is super for the period. I presume the marine engineers on the Olympic ships would have studied the drawings of the propulsion system prior to taking up their posts. They must have stood in the engine room (or should I say the engine great hall) in absolute awe when first encountering this completed and installed marvel of combined engineering skills. |

| Bob Rodgerson | 30/01/2017 23:57:09 |

| 612 forum posts 174 photos | When I worked at The Wallsend Slipway and Engineering Company on Tyneside they still had some pretty old lathes that were used to machine very large diameters such as the steam turbine rotors for the Mauritania. These were I believe about 15 ft in diameter, the reason for them being this large was that they were direct acting and didn't use a reduction gearbox . These large lathes had seats on the tool posts for the operator to sit in. |

| Ady1 | 31/01/2017 00:17:47 |

6137 forum posts 893 photos | Worlds largest lathe for sale Apparently you can go up to 3 miles between centres before the curvature of the earth affects your work |

| Ady1 | 31/01/2017 00:26:47 |

6137 forum posts 893 photos | They tended to hang on to them back in the day I recall reading about a battleship gun turret making lathe from around 1915 still around in one of the Scottish Shipyards in the 1970s, it had been sitting in a locked workspace within the shipyard for 60 years. |

| Andrew Johnston | 31/01/2017 07:12:55 |

7061 forum posts 719 photos | Posted by JasonB on 30/01/2017 19:16:18:

Did you notice the zig-zag herring bone gears in one of the photos Andrew? No, I had to have another look. I've no idea how to machine a double herringbone gear. An ordinary herringbone gear can be machined with a double ended shaper. Sykes were the main manufacturer of herringbone gear shapers, although Sunderland built a rival machine. It's not clear from the pictures but the apexes of the gear teeth look slightly rounded. Since the gears are part of the steering gear, and hence low speed, my supposition is that they are as cast, rather than machined. Of course now, with rounded apexes, they could be CNC'd. Andrew |

| Adrian Johnstone | 31/01/2017 07:59:58 |

34 forum posts | The Kempton Park engines were of similar size to the Olympic and Titanic's (though designed and built by Worthington-Simpson quite a bit later in the '20's). As probably most folk here know, one of the engine is still run on ten weekends of the year - 2017 schedule: **LINK** A visit is very well worth while. You will feel the earth move, and you can get a tour of the non-operational engine. Adrian Edited By Adrian Johnstone on 31/01/2017 08:00:37 |

| Roger Woollett | 31/01/2017 10:07:42 |

| 148 forum posts 6 photos | Another site you might like. http://www.shipsnostalgia.com/guides/William_Doxford_and_Sons Lots of machines making marine engines. Edited By Roger Woollett on 31/01/2017 10:08:57 |

| Hopper | 31/01/2017 11:32:47 |

7881 forum posts 397 photos | Posted by Roger Woollett on 31/01/2017 10:07:42:

Another site you might like. Lots of machines making marine engines. Edited By Roger Woollett on 31/01/2017 10:08:57 Great old photos. Thanks for posting. Now THAT's a ball turning attachment!

|

| Scrumpy | 31/01/2017 11:48:49 |

152 forum posts | What a lovely post thanks Jason it brings back so many memories for me on visiting Devonport Dockyard as an apprentice some 51 + years ago and having a ride on the planning machine as it was cutting a profile for engine beds , This was about 80 ft long and 30 ft wide they used to machine two beds at a time with 2 seats for the operator the tool holders were lifted in by chain blocks the travel was about one mile an hour health and safety would have had a field day I think it was made by hawthorn Leslie but I could be wrong |

| Mike | 31/01/2017 12:06:12 |

713 forum posts 6 photos | Jason, I really enjoyed that. If you want a modern slant on big engines (diesel), go to http://www.test.swiss-ships.ch/berichte/berichte/waertsilae/Wartsila-RTA96C-engine-technology-review.pdf Sorry about the long and clumsy link - perhaps when somebody has a few minutes they could teach me how to condense it into just "Link".

Edited By JasonB on 31/01/2017 12:19:36 |

| Mark Simpson 1 | 31/01/2017 12:42:06 |

| 115 forum posts 30 photos | Thanks Jason. Loved that. In the 80's and 90's NEI Parsons (Heaton Newcastle) and GEC large Machines (Rugby) were companies I regularly worked at (we provided the CAD system for them). They had some monster machine tools regularly working on parts of over 100 tons and bigger... I found this video from Parsons, some epic machine tools from about 9 minutes in,though the rest is also interesting... http://www.britishpathe.com/video/parsons-genius-of-power-reel-2-also-known-as I know what the "elf and safety" conscious of today will be wincing a bit Edited By JasonB on 31/01/2017 13:09:43 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

paternoster lifts, guys stood on the top of castings being poured, stood/sat on the toolpost of lathes and boring machines, no hi-vis...

paternoster lifts, guys stood on the top of castings being poured, stood/sat on the toolpost of lathes and boring machines, no hi-vis...

Register

Register Log-in

Log-in