Boxford as a wood lathe?

| Simon Wood 1 | 19/05/2016 12:50:54 |

| 6 forum posts 4 photos | Hi I have just started the hobby of pen making and have been using an old wood lathe but my Boxford TF280 is sitting there doing nothing at the moment. I just wondered if it is possible to fit a plain tool rest onto the boxford and if so where might I be able to buy one.The boxford would be a more accurate lathe and I also have a 240v speed controller fitted so it would be easier to change speeds for cutting and polishing Any info greatly appreciated |

| JasonB | 19/05/2016 16:28:39 |

25215 forum posts 3105 photos 1 articles | Simple solution is just to hole a round bar in the tool post and use that to rest your tool on, I do that when using a hand graver (metal turning by hand) . For a more long term solution then most of the woodturning suppliers sell various tool rests so it would just be a case of making something up so it can be mounted to teh cross slid ewhen the topslide is removed

Edited By JasonB on 19/05/2016 16:31:46 |

| Enough! | 19/05/2016 16:53:38 |

| 1719 forum posts 1 photos | This guy makes and sells some tool rests for a decent price - along with some other pen-turning stuff that may be of interest. He also makes some rather nice dead-centres with straight shanks which are useful outside of pen-turning (and hard to find). |

| Mike | 19/05/2016 18:15:05 |

713 forum posts 6 photos | I agree with Jason about clamping a length of bar in the tool post. I've done it many times myself. I'd also recommend that you cover the bed and the cross slide with newspaper. Fine wood dust creates horrible, sticky gook when mixed with oil and, if you're polishing with fine sandpaper there's also a possibility of getting abrasive grit on the bed. |

| Bazyle | 19/05/2016 18:21:42 |

6956 forum posts 229 photos | Ok if you are doing plastic pens maybe but wood is not nice around a metal lathe because of the oil. Wood lathes tend to be designed to avoid needing oiled running surfaces. My Bxoford model A was rescued from the carpenters shop at work and needed a complete strip down. |

| Muzzer | 19/05/2016 19:20:46 |

2904 forum posts 448 photos | Brown Stuff makes the most godawful mess. By the time you have hollowed out a bowl, you are ankle high in sawdust. And if you are turning wood that hasn't been dried out, it can be a wet business too. Not something to do to a machine you care about. In my case I bought a second hand wood lathe, made a few things on it then saw sense and managed to sell it on for more than I paid. A close escape indeed. |

| NJH | 19/05/2016 19:34:02 |

2314 forum posts 139 photos | For my money I would spend a bit of time " renovating" the wood lathe - that you have a metal lathe should help that process. I guess you will be using hand tools to shape the pen bodies and that process is surely just like wood turning. Having said that however I too have looked at a bit of pen making - and I passed my wood lathe on to my son in law some years ago! If I do proceed I will then be in the position of HAVING to use my metal lathe..........so let us know how you get on! Norman

|

| Roderick Jenkins | 19/05/2016 20:26:08 |

2376 forum posts 800 photos | Come on guys, wood's not that bad. For pen making, an engineering lathe seems to me to be a better option than most wood lathes. I've turned enough ebony and blackwood to make a set of Northumbrian bagpipes (still not finished, sadly) equivalent to about 50 pens without any noticeable damage to my Myford - not to mention all the little jigs and fixtures that it is useful to make out of wood from time to time. The shavings suck up the oil and it's best not to leave them lying around or they will trap moisture. Never going to do as much potential damage to the lathe as iron castings though. Rod |

| JasonB | 19/05/2016 20:36:11 |

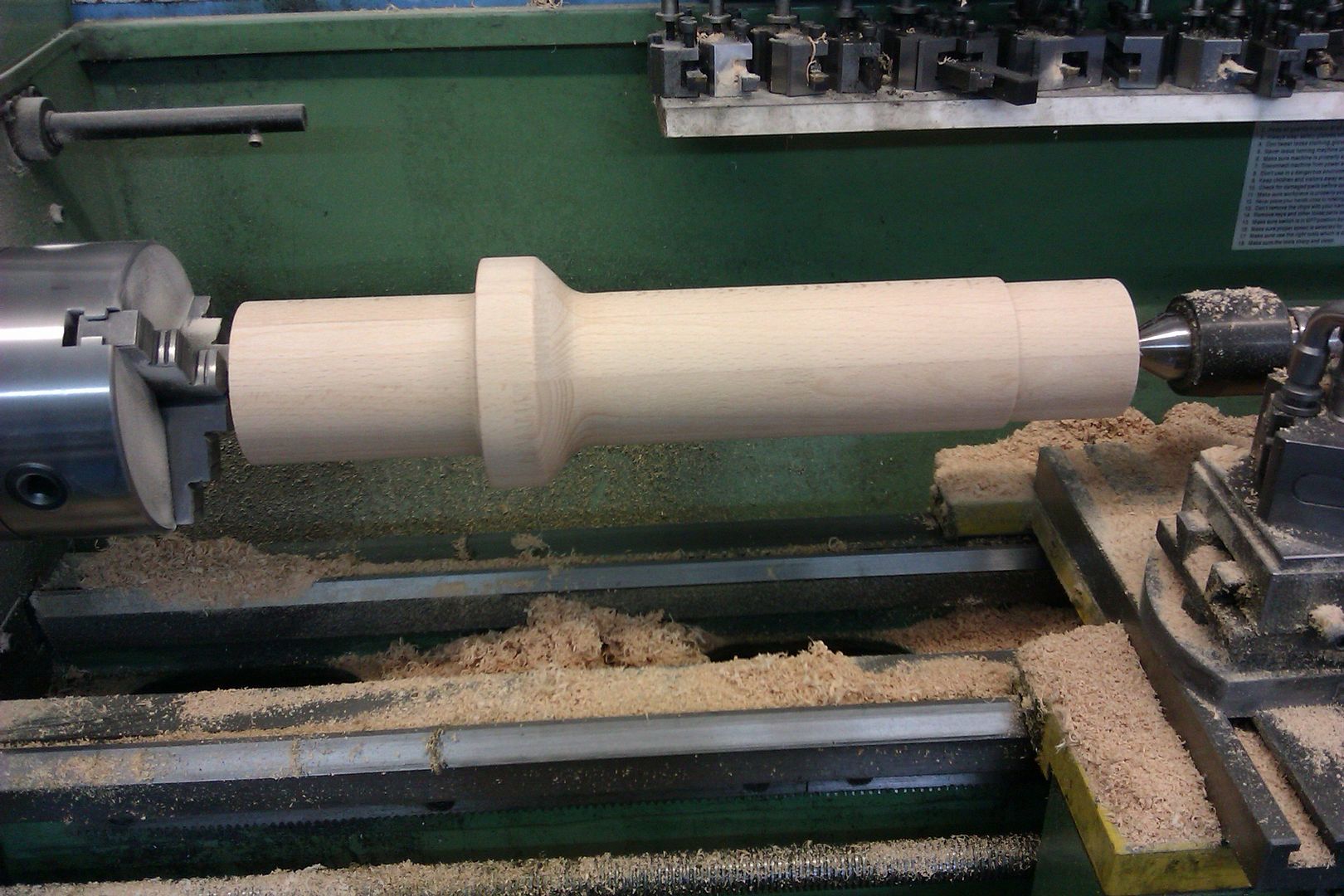

25215 forum posts 3105 photos 1 articles | As Rod says a bit of sawdust won't do much harm if cleaned up afterwards, I've done quiet a few detailed parts as well as pattern making on mine.

And this was knocked out on the Emcomat before I got a wood lathe.

Oh and I don't like to leave the mill out of things

|

| frank brown | 20/05/2016 06:15:11 |

| 436 forum posts 5 photos | I turned up a couple of matching spindles for my Victorian staircase. Biggest problem was that the lathe's speed was far too slow, so I interchanged the motor and lathe pulleys. The next problem was that their length (38" FWIW along the landing (28 spindles), no two spindles were identical when measured! The patterns were very close (+- 1/8" Frank |

| Speedy Builder5 | 20/05/2016 07:41:37 |

| 2878 forum posts 248 photos | The main problem would be the spindle speed not being fast enough, but as others have said, no problem for the lathe. I also use the mill for wood, routing and morticing, but again, spindle speed is not as fast as I would like which in turn blunts the end mills far quicker than when milling steel. |

| I.M. OUTAHERE | 20/05/2016 07:45:13 |

| 1468 forum posts 3 photos |

What really amazes me is that some people will turn cast iron and not give a damn about their machine but will tell you wood is the son of the devil itself , as long as you don't let wood dust sit too long as it will attract moisture you won't hurt you lathe . Wood is softer than cast iron and used to be used for bearings ! The only thing i see as a limiting factor is the spindle speeds , you can really crank up the speed on wood . If you take a look at the clickspring channel on youtube you will see him using a tool rest and a graver to turn brass in much the same way you use a rest and chisel to turn wood , you could make your own tool rest and leave the saddle at rest right up the tail stock end of the lathe nicely covered and protected from the so called evil wood dust ! Would love it see some of your work , maybe some pics ? Ian

Edited By XD 351 on 20/05/2016 07:50:02 |

| John McNamara | 20/05/2016 08:03:59 |

1377 forum posts 133 photos | Wood.... Wood! Not ideal. Easy to do but a lot of cleaning up after"woods". Regards |

| Jon Gibbs | 20/05/2016 09:33:20 |

| 750 forum posts | Simon, You don't say where you are but now you've read the scare stories, I have a Jet Mini 1014 woodlathe which is just the perfect size for penmaking I'll swap for your Boxford if you're too concerned about the damage Jon |

| Ady1 | 20/05/2016 10:35:33 |

6137 forum posts 893 photos | I did a wood job in my lathe workshop a couple of years ago A 5 minute woodturning job and a 2 hour cleanup, what a MESS and it was EVERYWHERE If I ever take up woodwork it will have it's own 100% dedicated space and plastic sheeting hanging about to limit the wood pollution EDIT: On a more serious note, wear a mask if you do take up woodwork Edited By Ady1 on 20/05/2016 10:40:29 |

| Simon Wood 1 | 05/07/2016 18:38:45 |

| 6 forum posts 4 photos | Hi Folks. Just want to say thank you for all your replies. I wanted to use the boxford because it has variable speed and is fantastically smooth compared to the old wood lathe. Reading about the cleaning up and low speeds I wonder whether just to sell the boxford and buy a mini lathe with variable speed. It seems a shame as its a fantastic lathe but is sat doing nothing.... |

| JasonB | 05/07/2016 18:50:08 |

25215 forum posts 3105 photos 1 articles | If you go down that route why buy a mini lathe? better to buy a small variable speed wood lathe |

| Neil Wyatt | 05/07/2016 19:51:47 |

19226 forum posts 749 photos 86 articles | One of these should not break the bank and allow you to keep the Boxford. www.machinemart.co.uk/p/clarke-cwl325v-13inch-mini-wood-lathe-with-ele/ Neil |

| Simon Wood 1 | 05/07/2016 20:15:21 |

| 6 forum posts 4 photos | i bought one of those in America and use it there when I get across on vacation. It only cost me £75 from a shop called Harbor Freight. They are cheap and rough and ready but actually manage to do the job for pen making. I would like to get back into small bowl turning so would probably go for something just a little better. Im not adverse to buying used so would keep an eye on gumtree. The Boxford is nothing but an ornament at the moment so I think it has to go. |

| Bob Brown 1 | 05/07/2016 21:55:33 |

1022 forum posts 127 photos | Wood can not be as bad as cast iron and I've used the mill and lathe for both even machining halving joints for work bench. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

exceeded my bed length so I drilled two holes in the end of the bed and bracketed out a ball bearing centre. I also had to conjure up a fixed steady that did not mark the wood. It all worked very well.

exceeded my bed length so I drilled two holes in the end of the bed and bracketed out a ball bearing centre. I also had to conjure up a fixed steady that did not mark the wood. It all worked very well.

Register

Register Log-in

Log-in