Oils seals, which way to install?

which way around to install tiny oil seals.

| Ed Duffner | 02/04/2016 19:45:06 |

| 863 forum posts 104 photos | Hi everyone, For the rotary broaching tool I'm making I'd like to add in a small oil seal at the rear of the tool to act as a barrier against dirt and moisture. Is there a preferred way to install these or does it not matter? One end of the seal has been reduced into a kind of swaged chamfer. The opposite face has the rubber seal going from the ID, up over the face and all the way out to the OD. These are 16mm OD to fit a12mm shaft. Thanks, Ed.

|

| KWIL | 02/04/2016 19:55:58 |

| 3681 forum posts 70 photos | Usually "hollow" side in towards the fluid. |

| Ian P | 02/04/2016 20:35:52 |

2747 forum posts 123 photos | Posted by KWIL on 02/04/2016 19:55:58:

Usually "hollow" side in towards the fluid. 'Fluid' in this case being air so the seal lip and spring would be visible after assembly. If the shaft is lubricated and you want the oil seal to prevent the oil escaping then the seal lip and spring would need to be on the the oil side. Ian P |

| ChrisH | 02/04/2016 20:44:59 |

| 1023 forum posts 30 photos | If you think about it, I feel you want the 'hollow' side of the seal to be against whatever you are protecting the other side of the seal from, be it dirt, water, oil leakage out, whatever, so the pressure on the 'hollow' side is pressing the seal tighter to the shaft to resist ingress rather than the other way round, if that makes sense. Chris |

| Ed Duffner | 02/04/2016 21:35:23 |

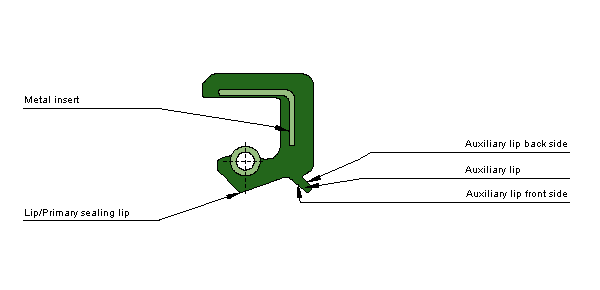

| 863 forum posts 104 photos | Thank you guys, There's no spring on the seal, I think because it's so tiny. I knocked up a quick sketch in Fusion 360 of the cross section.

|

| Robert Dodds | 02/04/2016 23:35:11 |

| 324 forum posts 63 photos | Ed, Bob D |

| Robert Dodds | 02/04/2016 23:35:12 |

| 324 forum posts 63 photos | Ed, Don't want to repeat myself! Bob D Edited By Robert Dodds on 02/04/2016 23:37:50 |

| Ed Duffner | 03/04/2016 01:01:32 |

| 863 forum posts 104 photos | Hi Bob, Thanks for the pointers. This will be a rotary tool, so no sliding motion. Here are some more pictures with decriptions. Ed.

The red coloured section of the larger diameter part is yet to be parted off. I will hopefully be doing this tomorrrow(today). This will leave a flat wall at the back of the tool to take the seal.

The body is made up of 2 brass sections which sandwich and hold concentric a couple of bearings that have been pressed onto the 12mm dia shaft. The brass body and bearings all rotate together around the shaft which will be fixed and held in a QCTP tool holder. ...(I may need to redesign the shaft with a shoulder on it to bear against the bearings).

Once I've parted off that rear section I will need to machine a counter-bore to take the seal. This will be to prevent any dirt etc from getting between the stationary shaft and the revolving body.

Here's a pic showing the rear as it is now with the seal on the shaft. The stepped part is just an existing feature from the brass offcut I used and will be machined off as mentioned above. Edited By Ed Duffner on 03/04/2016 01:27:21 |

| John Reese | 03/04/2016 02:34:22 |

1071 forum posts | Beautiful work. A quick rule for seals: Lip facing in to keep lubricant in, lip facing out to keep dirt out. You probably want to keep dirt out. |

| Ed Duffner | 03/04/2016 03:23:44 |

| 863 forum posts 104 photos | Thank you John |

| Michael Wade | 03/04/2016 05:37:37 |

| 2 forum posts | Your seal looks very much like a self energising hydraulic component seal far too sophisticated and expensive to keep dirt out. A very ordinary HMI 16 x 12 should fit the bill Nice shiny turning Michael Wade |

| oldvelo | 03/04/2016 22:58:53 |

| 297 forum posts 56 photos | Posted by John Reese on 03/04/2016 02:34:22:

Beautiful work. A quick rule for seals: Lip facing in to keep lubricant in, lip facing out to keep dirt out. You probably want to keep dirt out. Hi Ed John is spot on can I add a little more. the bearings are rubber sealed so no lubricant on the seal so a dab of grease on the shaft before fitting the seal. There are "Double Lipped" Seals available with smaller secondary lip to keep dirt out and lubricant in. Or a felt grommet soaked in oil instead of a modern seal will keep the swarf out. Eric |

| John Reese | 04/04/2016 02:38:03 |

1071 forum posts | In my earlier posts I neglected to mention that there are seals with dual lips. They provide against lubricant loss and exclude dirt. I have not looked at a seal catalog and I know know nothing of what is available in the UK so I can't make a specific recommendation.

Just did a quick search. SKF and Timken offer oil seals. They should be available in the UK. Edited By John Reese on 04/04/2016 02:41:03

Here is SKF info. http://www.skf.com/group/products/seals/industrial-seals/power-transmission-seals/radial-shaft-seals/index.html Edited By John Reese on 04/04/2016 02:43:52

Edited By John Reese on 04/04/2016 02:45:12 Add Garlock to the list of sources. Edited By John Reese on 04/04/2016 03:06:34 |

| Paul Lousick | 04/04/2016 07:28:16 |

| 2276 forum posts 801 photos | The normal rotary shaft seals do not allow for much side-ways movement. It may be better to use a Vee ring seal. They are inexpensive and easy to fit and available from most bearing suppliers. No special machining required. Just press over the shaft. Paul. |

| Gordon W | 04/04/2016 09:32:52 |

| 2011 forum posts | Paul- thanks for that, V ring. I've been searching and could not remember what they are called. Used a lot in the past on agricultural stuff, keep dirt out, also at speed will "fling" out so less friction on the face. |

| Martin Kyte | 04/04/2016 10:46:09 |

3445 forum posts 62 photos | Shout if I'm wrong but my understanding is that the sealing lip goes on the inside so that over-pressure in the oil casing will cause the seal lip to be pushed against the shaft and increase the sealing pressure. In this case as there is no differential pressure I cannot see it matters overly. Think I'd go with John Reese's rule. Martin |

| Ed Duffner | 04/04/2016 13:12:15 |

| 863 forum posts 104 photos | Thanks guys, I've now completed the tool and installed the seal as per the orientation in last photo I posted above i.e with the chamfer pointing outward.

Best Regards, Edited By Ed Duffner on 04/04/2016 13:13:01 |

| Martin Kyte | 04/04/2016 15:22:00 |

3445 forum posts 62 photos | Really not worth changing your already very good job but for dirt exclusion without friction you would probably have to opt for a labyrinth seal as used on such things as the Quorn Cutter Grinder spindle. Essentially you engineer a convoluted path of ingress to keep the dirt out. |

| Howard Lewis | 07/04/2016 17:06:25 |

| 7227 forum posts 21 photos | If you choose a labyrinth type sealing arrangement, the "thread" should be of a hand that screws any dirt outwards, (NOT inwards) under normal direction of rotation. Some lipseals are available with a "thread" on the outer side of the lip, but again, are only effective if the rotation of the shaft moves debris away from the lip. Metal shields on ball bearings exclude large particles, "rubber" seals (as in bearings with "2RS" suffixes are much more effective in keeping out small particles. Talk to Ketan at Arc Euro about these types of shields and seals. Howard |

| Ed Duffner | 07/04/2016 18:03:25 |

| 863 forum posts 104 photos | Thank you for the info chaps. I think the labyrinth is a bit involved for my skill level at the moment - very clever idea! I also like the idea of the felt washer. I'll see how it goes with this rubber seal for the moment and how warm the tool gets. I don't think it will be too bad as it would be used interrmittently. Cheers, |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in