Trident vertical milling machine restoration

| Mark Prickett 2 | 15/03/2016 16:58:16 |

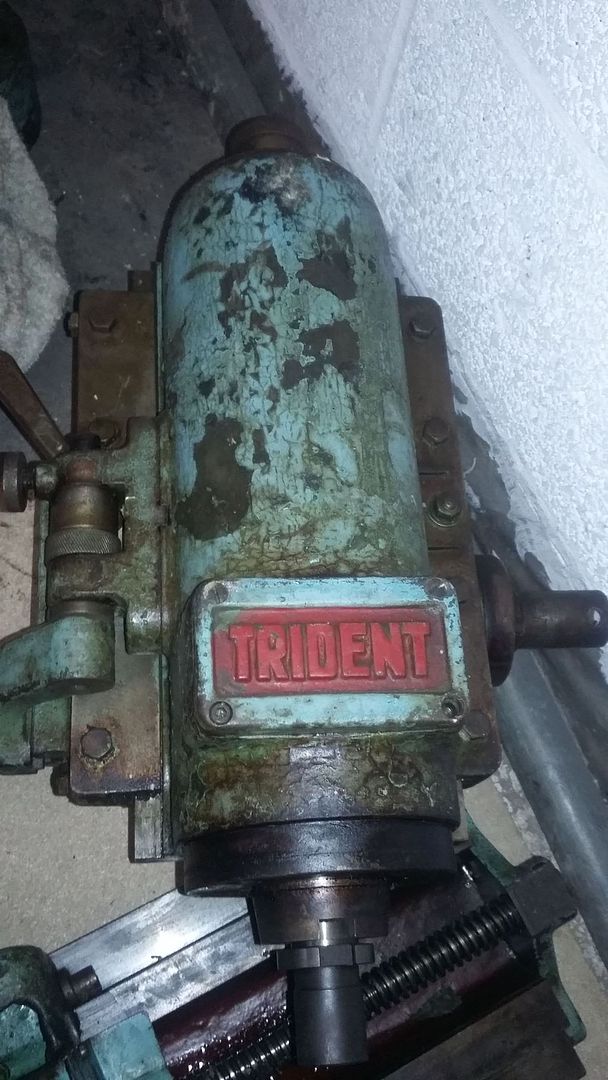

| 75 forum posts 10 photos | On my quest to find a vertical milling machine i will hopefully be having this delivered on saturday . this is what it should look like...

and this is the machine itself.....

Edited By Mark Prickett 2 on 15/03/2016 16:58:34 |

| Michael Gilligan | 15/03/2016 17:39:02 |

23121 forum posts 1360 photos | Ten minutes with Photoshop should do the trick MichaelG. |

| Mark Prickett 2 | 15/03/2016 17:47:06 |

| 75 forum posts 10 photos | Ha I wish it was that easy Michael! Thanks for the reply |

| Michael Gilligan | 15/03/2016 17:50:13 |

23121 forum posts 1360 photos | Definitely looks worth the effort, even if you have to do it the hard way, Mark MichaelG. |

| Chris Evans 6 | 15/03/2016 20:10:33 |

2156 forum posts | That looks a useful machine, what sort of size is it ? Looks a smaller footprint than my Bridgeport but pictures are deceiving. |

| Mark Prickett 2 | 15/03/2016 20:29:32 |

| 75 forum posts 10 photos | Thanks Chris. It's footprint is 30"deep by 27" wide. Table size is 30"x7" |

| Ajohnw | 15/03/2016 20:30:49 |

| 3631 forum posts 160 photos | Nice looking chunk of cast iron that plus timken roller bearings. Some of the old millers about use plain ones = tough to replace. That one is more like my dream machine if I had real workshop. There have been a few on ebay lately. The type a die sinker might use. I noticed what you have probably paid for yours (well done) while looking for a machine with a name that I hadn't heard of before and liked the look of. - gate jarocin - a pipe dream for me though. Totally OTT too but ............. John - |

| Chris Evans 6 | 15/03/2016 20:54:27 |

2156 forum posts | "The type a die sinker might use" I spent most of my working life as a "Die Miller" The rest working spark erosion machines where the die milling skills where needed to produce the electrodes. |

| Ajohnw | 15/03/2016 23:30:14 |

| 3631 forum posts 160 photos | Posted by Chris Evans 6 on 15/03/2016 20:54:27:

"The type a die sinker might use" I spent most of my working life as a "Die Miller" The rest working spark erosion machines where the die milling skills where needed to produce the electrodes. This is the type I mean. There has been several machine of this general type and shape of late. Guess it might be down to spark erosion.

https://www.flickr.com/photos/48994619@N08/?

John -

Edited By Ajohnw on 15/03/2016 23:30:33 Edited By Ajohnw on 15/03/2016 23:42:02 |

| Mark Prickett 2 | 18/03/2016 09:29:26 |

| 75 forum posts 10 photos | Looks like im going to have to strip this to move it as access is a pain to say the least, engine crane , combo van and estate car it is then ! im thinking take the head off, the table and the knee? how do we think these are all attached? wish me luck people! |

| mark smith 20 | 18/03/2016 09:50:50 |

| 682 forum posts 337 photos | Looks very nice , ive been after a decent mill for years but i have no idea how i would get it into my workshop in the back garden down a narrow path with steps up and down and no driveway.. Its a shame when you can often pick them up very cheap. I was considering this Arno mill only a few miles from me but the weight put me off! Edited By mark smith 20 on 18/03/2016 10:02:07 Edited By mark smith 20 on 18/03/2016 10:02:45 |

| Ady1 | 18/03/2016 10:21:59 |

6137 forum posts 893 photos | Good luck, a nice looking bit of kit, I only found a single entry in my database for Trident gear from June 1958 MADE IN GERMANY '2 |

| Ian S C | 18/03/2016 11:30:29 |

7468 forum posts 230 photos | I don't know about post WW2, but before the mid 1930s Whitworth was the normal thread used in German machinery, I found that when working on Lanz Bulldog tractors. Ian S C |

| Ajohnw | 18/03/2016 13:35:58 |

| 3631 forum posts 160 photos | Posted by mark smith 20 on 18/03/2016 09:50:50:

Looks very nice , ive been after a decent mill for years but i have no idea how i would get it into my workshop in the back garden down a narrow path with steps up and down and no driveway.. Its a shame when you can often pick them up very cheap. I was considering this Arno mill only a few miles from me but the weight put me off! Edited By mark smith 20 on 18/03/2016 10:02:07 Edited By mark smith 20 on 18/03/2016 10:02:45 Contact the army or similar and tell them you have a challenge for one of their larger helicopters. Reminds me of a machine being developed that after it was built couldn't be got out of the building. A director oddly known as Bomber Harris said no problem I will get the army in to remove a section of roof and we will air lift it out. As it turned out the machine couldn't be used in practice so I have no idea what happened to it might still be there. The engineer in charge must have spent 8 years working on it with pretty obvious flaws even with the concept yet was still promoted to a very high position afterwards. John - |

| Ajohnw | 19/03/2016 16:59:04 |

| 3631 forum posts 160 photos | There is another interesting universal on ebay. I would wonder about these using plain bearings and it's probably pre ww2 Looks like it may have the end support for the horizontal arbour but if that is what's in the box it might be a bit small. John -

|

| Cornish Jack | 19/03/2016 17:30:51 |

| 1228 forum posts 172 photos | "Contact the army or similar and tell them you have a challenge for one of their larger helicopters." Yes, well mmm?! Story from times past, possibly apocryphal ... One of our 'sister' S&R flights was based on an ex WW2 airfield which retained the reinforced blast walls of the time. The operational Standby aircraft (Whirlwinds) were parked in these areas and had had rotor start-up problems (blade-sailing) in windy conditions. Local permission was granted to get 'Works and Bricks' to remove the walls. Local Boss had a whizz idea - get the local TA chaps to blow them up as a training exercise - they were obviously good with noise makers and stuff!! Holes drilled in walls, explosives inserted, packing to complete etc. , retire to safe distance, BANG!! ... Wall remains intact, S&R Standby aircraft, now with broken oleo, mucho collapso It WAS a long time ago and nobody would do such a thing nowadays, would they?? rgds Bill |

| Mark Prickett 2 | 22/03/2016 20:17:43 |

| 75 forum posts 10 photos | well here she is home , took longer than expected and a lot heavier than expected ! without an engine crane we wouldent have moved it at all! cant find anything wrong with it yet other than a few oil leaks which are easy fixes. some slight backlash which is to be expected with a machine of this age . has lots of coats of paint on , in some areas 5mm thick! does anyone know what colour this would have been from new?

Edited By Mark Prickett 2 on 22/03/2016 20:26:12 |

| John Fielding | 24/03/2016 08:49:25 |

| 235 forum posts 15 photos | Congratulations! Looks like a good piece of kit to have. If the original pictures of the miller are anything to go by then the table looked in excellent condition. No obvious dings or other damage, so it has been well looked after. Things like slideways etc can always be fettled, but those generation of machines were built to last. As long as no cracks etc then all it should need is some TLC and it will run for another 50 or so years! |

| Ajohnw | 24/03/2016 10:55:37 |

| 3631 forum posts 160 photos | Nobody took the Thiel I linked to on. Given space it would tempt me - changing to horizontal isn't a back breaking job. It is on some. John - |

| Hopper | 24/03/2016 12:12:45 |

7881 forum posts 397 photos | Looks like a very nice bit of kit. An archeological dig to the bottom of that 5mm of paint might reveal the original color. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

A real vert. miller and OTT for home use unless I went into drop forge die sinking.

A real vert. miller and OTT for home use unless I went into drop forge die sinking.

Register

Register Log-in

Log-in