Member postings for Mark Prickett 2

Here is a list of all the postings Mark Prickett 2 has made in our forums. Click on a thread name to jump to the thread.

| Thread: Trident vertical milling machine restoration |

| 21/06/2016 11:52:03 |

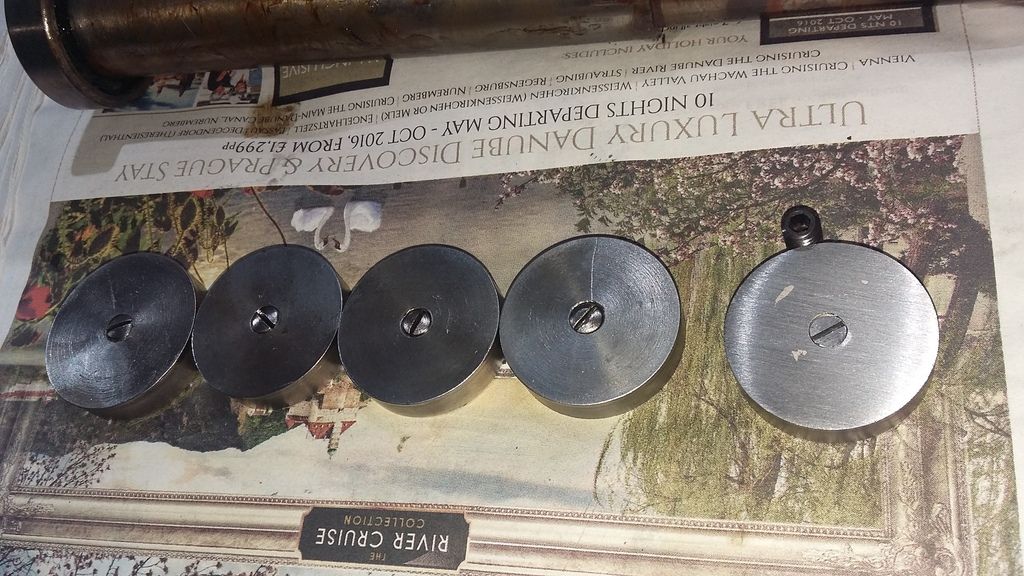

these are all the caps that cover the end of the bearings that go into the casting, 4 cleaned up well but the one on the far right looked like it had been beaten on with a hammer, (sorry no before pics)

the other caps on the end cover the other ends of the bearing mainshafts.

|

| 19/06/2016 17:07:20 |

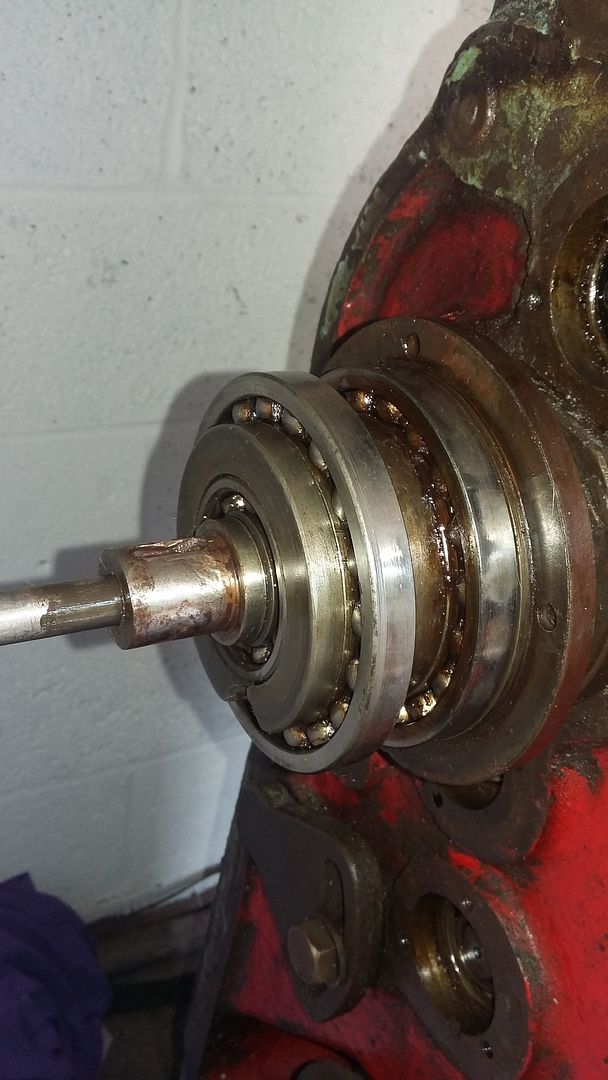

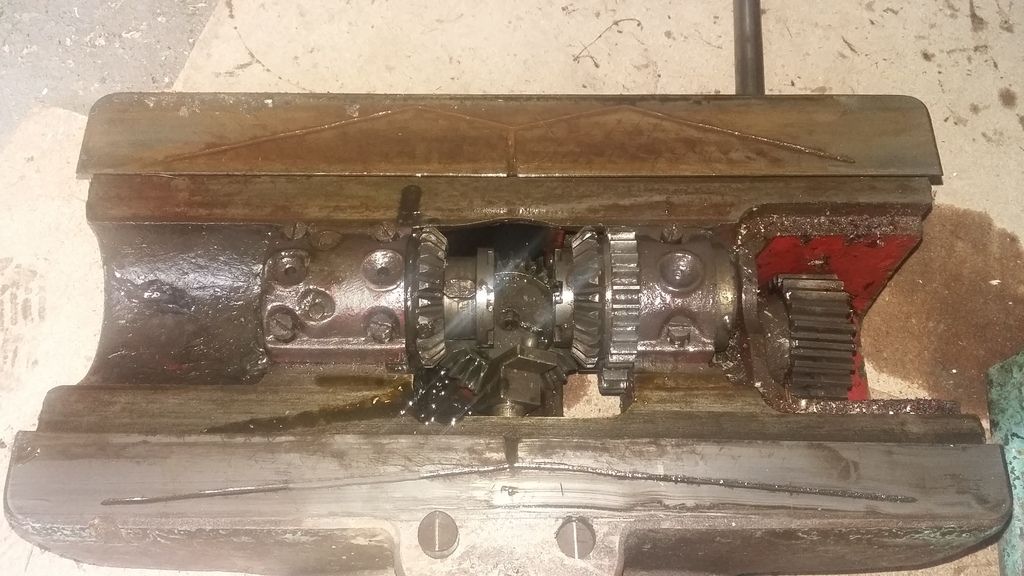

After lots of t , lots of looking , and some head scratching i came up with a plan.

Slide hammer the disks out ... Smack the end of the shaft with a big brass drift and it started to move !

Your never sure if your doing the right thing but as you can see its really filthy in there , think i will have to remove all the shafts and clean it out before i can repaint the inside and renew all the bearings etc ..... |

| 17/06/2016 19:57:22 |

thanks Vic!

so this is the rest of the machine as it stands at the moment

not sure what to tackle next ! Im thinking of having this sandblasted ,it would be much easier, dont think i can face chiseling off all that paint !

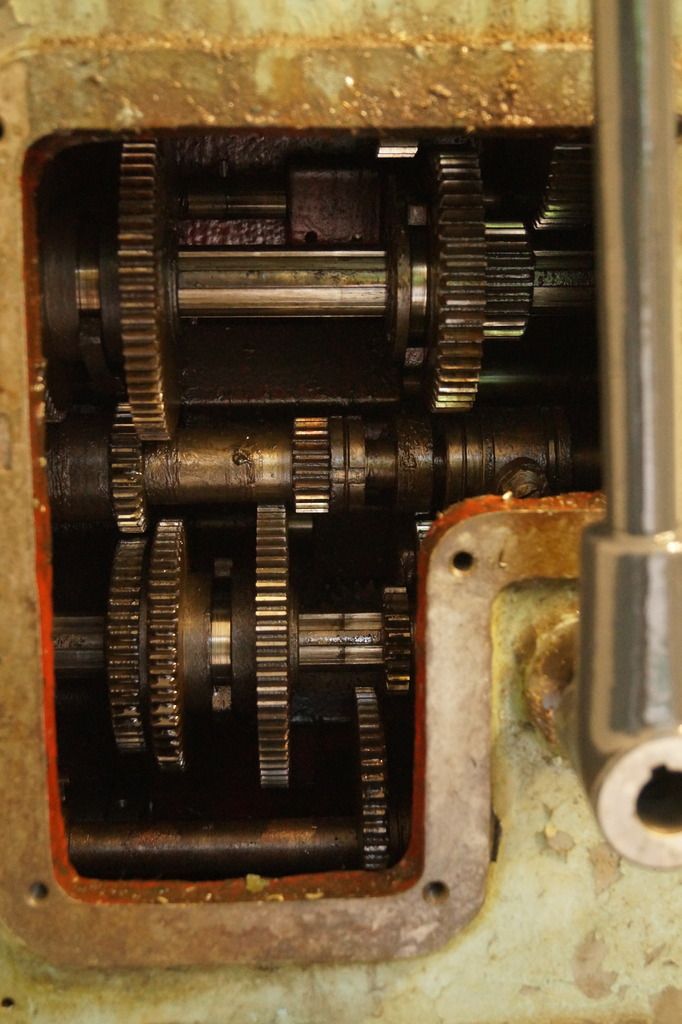

was planning on leaving the internal workings well alone , but the state of them , its really filthy in there , plus i could change all the bearings on the end of the shafts.....

you can just about see all those end caps on the back of the machine , i assume you could draw the shafts through them , no idea how though as everything so far has been make it up as i go along! i have no manual to speak of.

|

| 17/06/2016 15:10:39 |

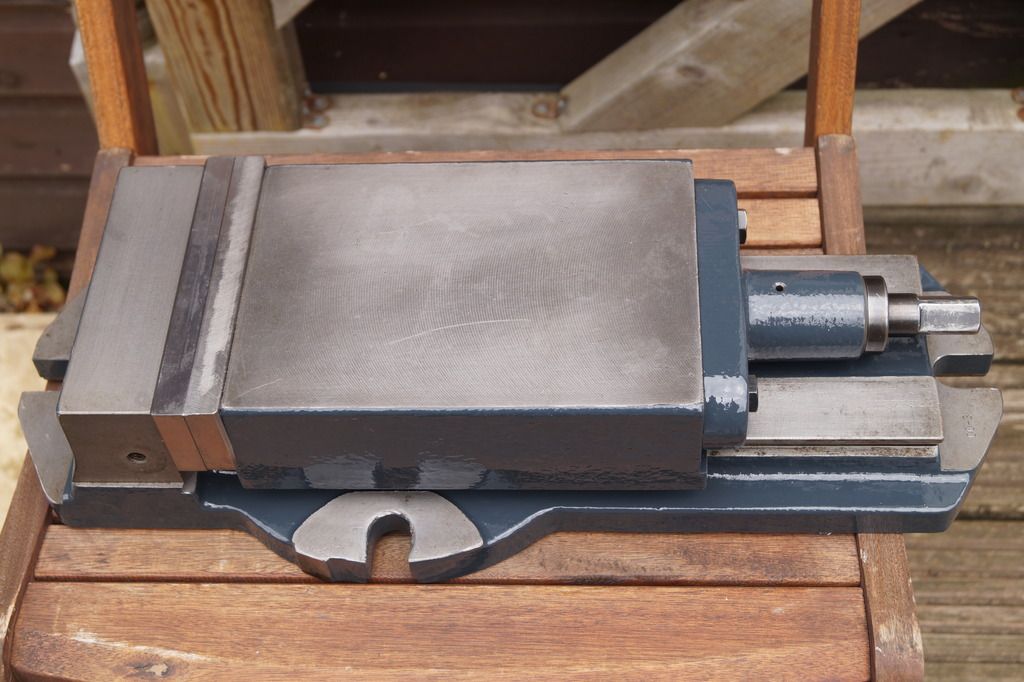

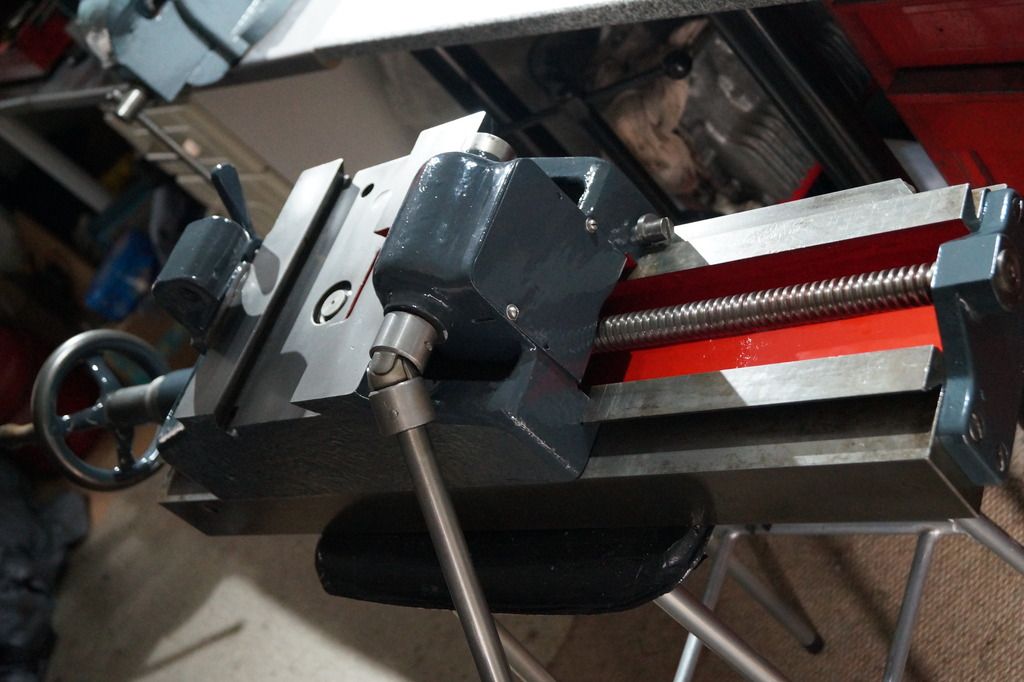

finished the vice off , seller said it opens to 4", that was only because of all the swarf in it , now it opens to 6.5"

and mounted the gearbox on the bed , everything is still upside down at this point obviously

|

| 15/06/2016 18:56:38 |

so ive been stripping the main shaft that connects to the head .....

came apart in about 10 seconds

but oh my did it take a long time to put it back together correctly .... you are looking at about 2 hours here. one of those jobs that you think will take 5 mins but takes ages!

skf bearings came out so skf went back in ! |

| 13/06/2016 18:58:08 |

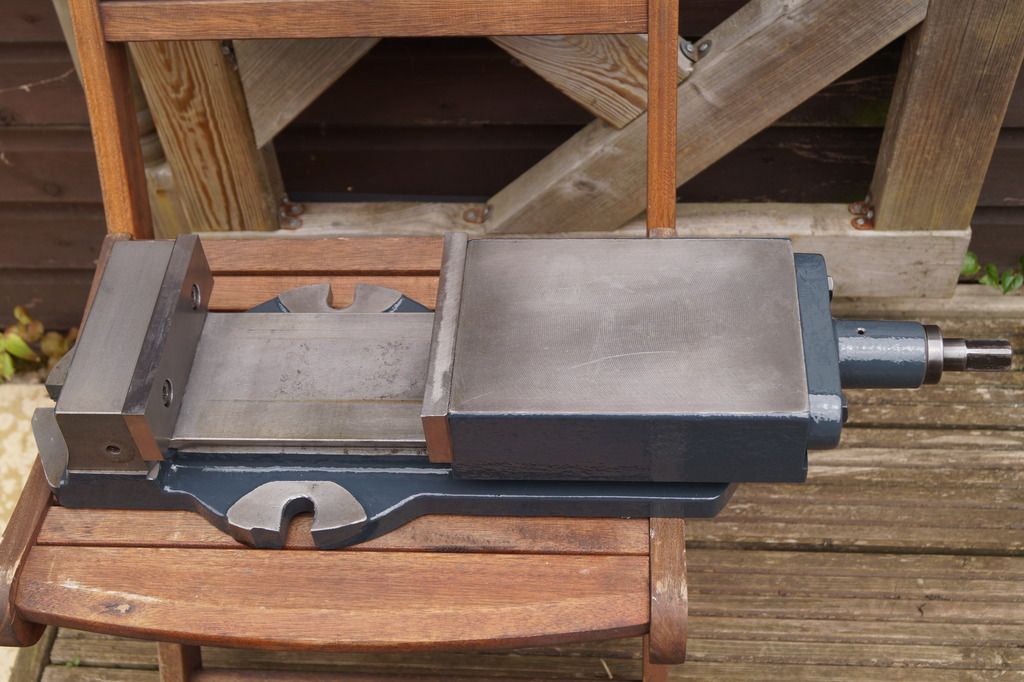

on another note i found a nice vice for it .....

thought i would strip it as its nowhere near clean enough for me , and needs a lick of paint.

good job i stripped it !

more pics when its been cleaned / painted! |

| 13/06/2016 18:55:01 |

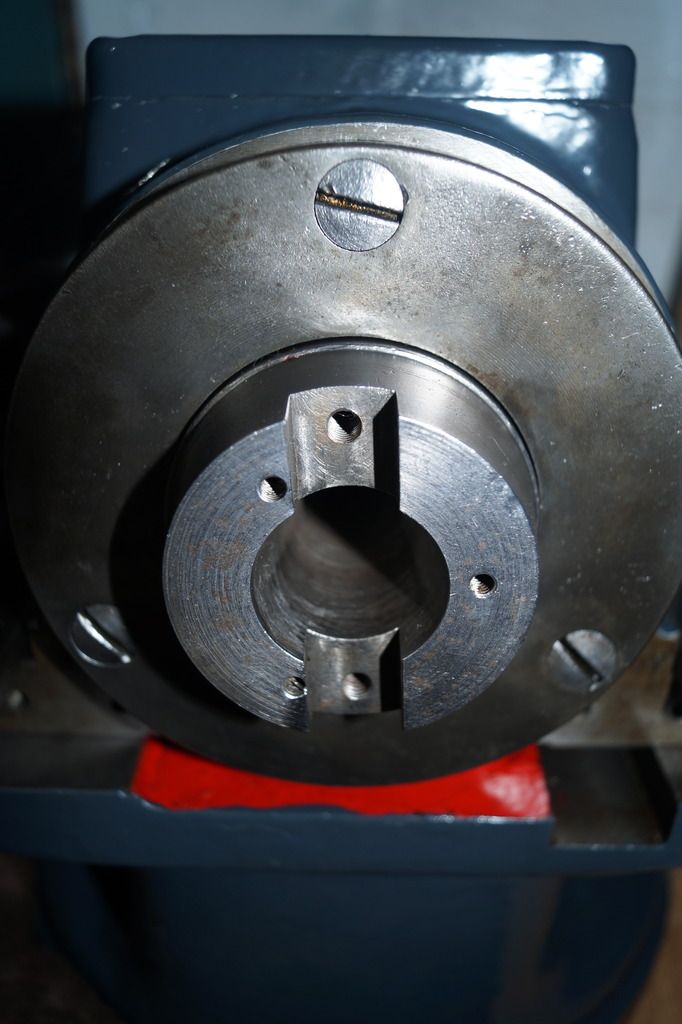

so i originally thought this was an mt3 taper as that's what was suggested on the lathes.co.uk website . but it has been suggested that its a 30Int fitting ? here are some pics

|

| 10/06/2016 13:04:07 |

Posted by Muzzer on 10/06/2016 12:47:19:

Hi Mark Looking good - almost too good to use! What is the hyper-glossy paint you have used? Is it some fancy epoxy concoction? Murray thanks Murray , its this stuff from smith and allen , awesome paint the best ive used so far . really glossy and dries within about 6 hours , enough to put another coat on anyway. |

| 10/06/2016 06:45:09 |

oh one interesting fact (well i find it interesting anyway, depends on your perspective ) is everything , and i mean every thing , has a number 6 or 9 on it cant make my mind up which. even down to washers and bolts

|

| 09/06/2016 19:50:17 |

here is the table before hand , on it is a 12mm drill gives you an idea of the size , its about 30" long.

and here are the grub screws

some damage i found , but not sure if it will detrimental to the machine , or if it could even be repaired.

|

| 09/06/2016 19:09:31 |

onto the table tomorrow as i have the day off, doesn't look like much damage if any which is a bonus . seems to have grub screws in the base of it that you undo to oil the gearbox underneth. underneth it is red like the rest of the gearbox so lots more painting to do! |

| 09/06/2016 19:05:06 |

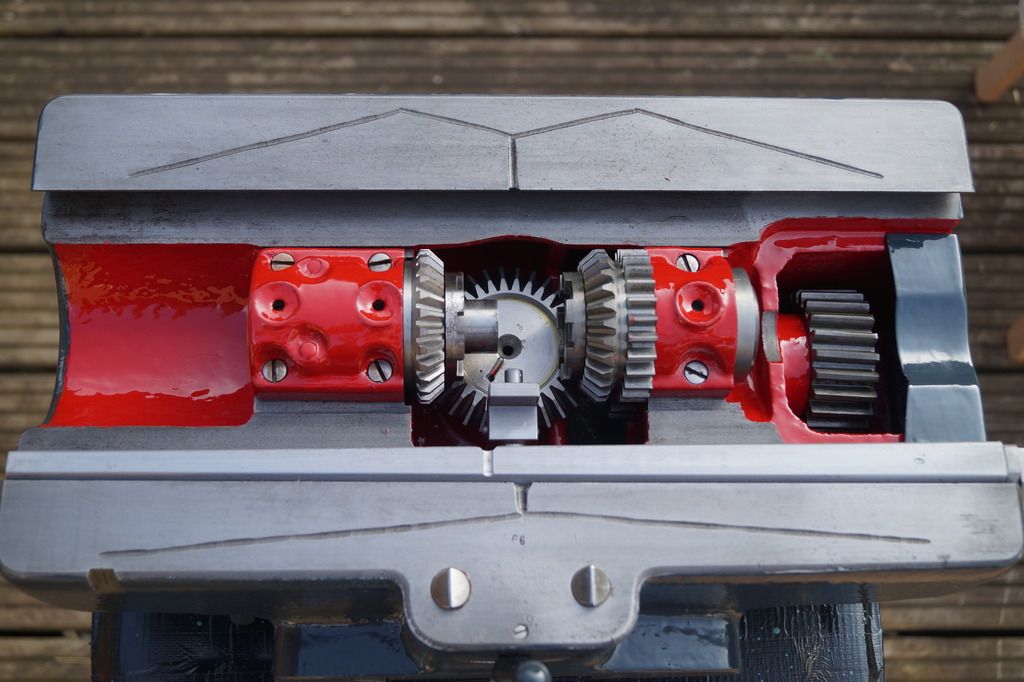

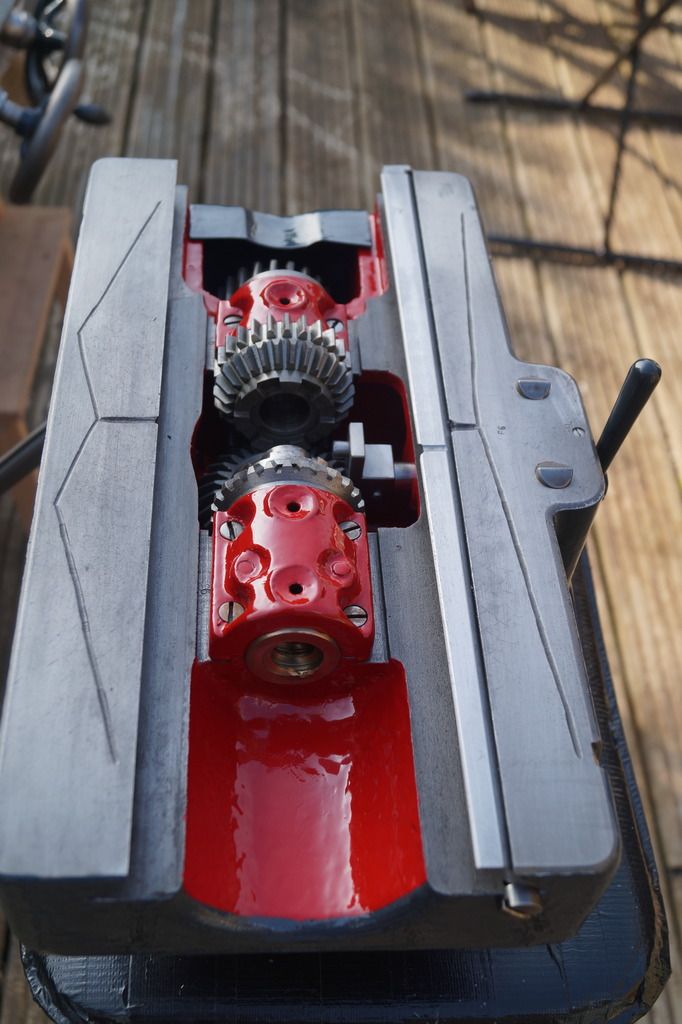

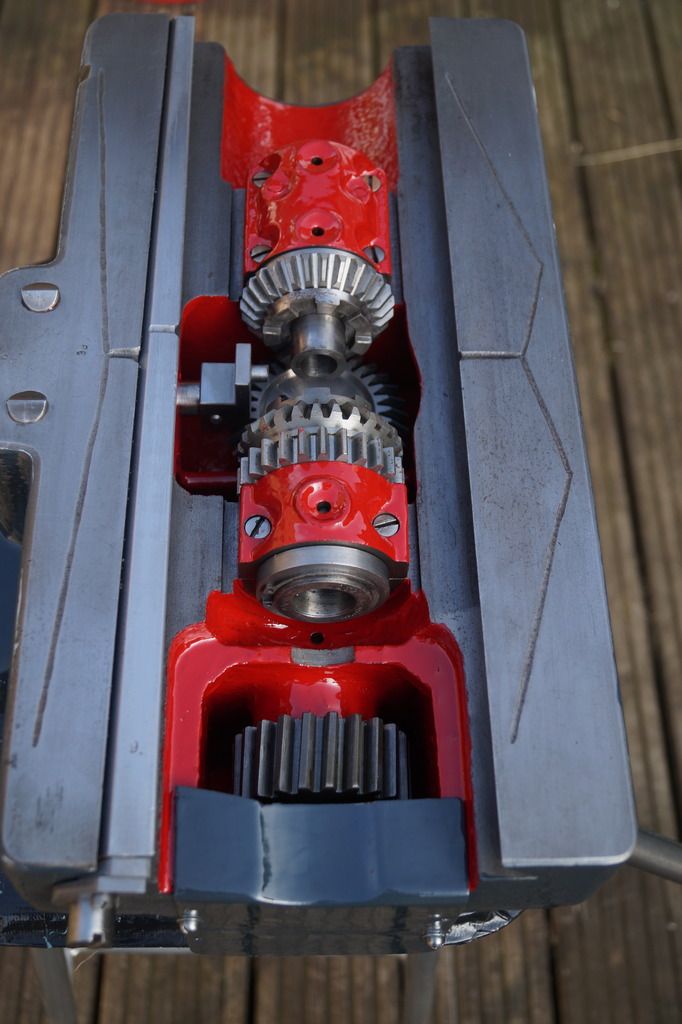

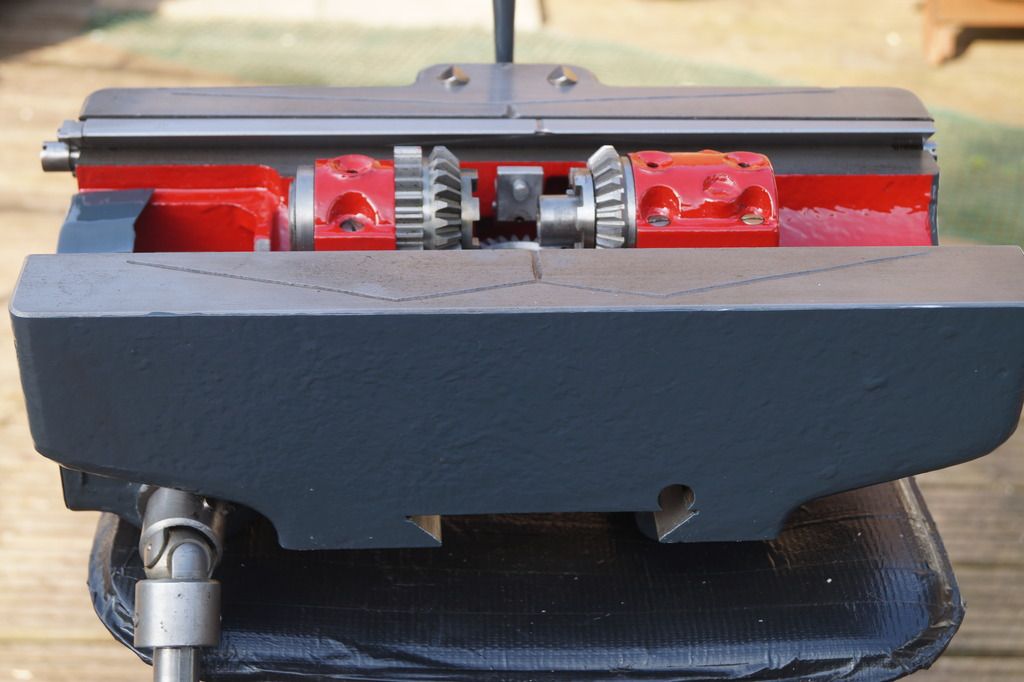

onto the gearbox that sits under the table. only 1 picture before , but boy was its filthy in there , 50 year old grease is not nice , even petrol would hardly budge it .

not complete yet as im waiting on a few more bolts to turn up.

|

| 09/06/2016 18:30:44 |

Posted by damian noble on 09/06/2016 13:07:10:

Lovely restoration work thanks Damian, a bit of an update ........

stripped the knee down , paint work wise it was in a right state , but the meahnicals of it seem fine . i have replaced the bearing at the top of the shaft that raises and lowers the knee as it takes alot of weight . £28 for one bearing!

and after

still need to find a new nut for the wheel on the left , and sort out some kind of handle .

more pics after ive had me t |

| 09/06/2016 18:19:27 |

Posted by Neil Wyatt on 01/05/2016 20:57:01:

Very nice Mark, how about a short article with some extra details for MEW? Neil Thanks Neil , im not much of a writer i dont think i would be up to the task but i take that as a compliment so thankyou! |

| Thread: Super 7 |

| 03/05/2016 09:57:00 |

Posted by Lambton on 03/05/2016 07:38:40:

Mark, You only really require one C spanner. You can get away with and old cycle bottom bracket spanner that can be found at car boot sales for a few pence. There is a picture of one being used on this site from Nobby I think. Otherwise make one. A bit of marking out, chain drilling, hacksawing and filing will do it. This is what model engineering should be about - getting satisfaction from making your own tools and fixtures as the need arises. Eric

thanks Eric , Robbo has very kindly offered to lend me a set of spanners.

|

| 03/05/2016 09:56:29 |

Posted by richard 2 on 03/05/2016 08:20:30:

Mark I have a Dewhurst switch and Myford bracket (taken off my S7 when I went 3-phase which you are welcome to for nothing. But as I am disabled you would have to collect it from Henfield in West Sussex. If it is of interest pm me and let me know. Richard. Many Thanks Richard for your vey kind offer., i have a nearly new Dewhurst switch and bracket to go on it but need to sort out a motor starter with overload protection for it , cheapest i have seen is £29 delivered . Although i will need much help with the wiring! |

| 02/05/2016 18:24:50 |

Its on the "list" george but funds are tight at the moment I like the one from rdg tools **LINK** |

| 02/05/2016 17:45:21 |

Oh if anyone has any small bore c spanners i can borrow to adjust up the headstock bearings i would very much appreciate it, obviously I would pay for posting costs etc. And still looking for a dol starter for it and an oil gun ! Cheers Mark. |

| 02/05/2016 17:42:56 |

|

| Thread: Trident vertical milling machine restoration |

| 01/05/2016 15:23:11 |

Finished the head today , all new bearings etc . Just got to sort out the draw bar for it , hope fully someone on here will be able to help me ?

|

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in