Beginner question - holding a piece of already machined aluminium in a lathe chuck.

| Gas_mantle. | 12/06/2015 09:24:37 |

359 forum posts 269 photos | Hi all, I'm hoping someone may be able to assist a complete beginner. I want to hold a piece of 1.25" dia aluminium in my lathe chuck to machine the other end, I've already machined the end that needs to go in the chuck (I appreciate I probably didn't think ahead but it's too late now). It's not crucial that the already machined end isn't marked by the chuck but for cosmetic reasons I'd rather it wasn't and can't take anymore of the diameter. Any advice on how to hold it without marking ? I thought about cutting up small pieces of aluminium beer cans to line the jaws but if anyone knows a better way I'd be grateful. I guess one advantage of the beer cans is it's a good excuse to go and get a 4 pack for later Peter. Edited By Peter Nichols on 12/06/2015 09:25:42 |

| JasonB | 12/06/2015 09:34:35 |

25215 forum posts 3105 photos 1 articles | You can wrap a piece of paper or beer can around the work, just watch any cut edges on the can. Or just place a piece of flat aluminium or perspex/acrylic sheet between jaws and work.

|

| Gas_mantle. | 12/06/2015 09:41:06 |

359 forum posts 269 photos | Thanks Jason, beer cans it is One thing I have learned so far is to think ahead next time, at the moment I'm still sometimes remachining ends of work I already previously had set up because I'm not always getting the operations done in the correct order. In some cases the very piece of the work I need to hold in the jaws for the next operation is the very same piece I've just cut off !! Peter. |

| Ian S C | 12/06/2015 11:15:16 |

7468 forum posts 230 photos | It can be useful to sit down with pen and paper, and list the opperations required, I did this when I started lathe work, and it worked for me. In those days I drew everything, Now I tend to get going, and see what happens. Protection, thin cardboard,heavy paper, or aluminium, and not just for aluminium work, but steel, and all other metals. With steel, some bits of steel can help prevent the jaws marking say the sides of a square in the 4 jaw chuck. Ian S C |

| Gas_mantle. | 12/06/2015 12:01:53 |

359 forum posts 269 photos | Thanks Ian, I give that a try. I'm just getting past the 'swarf making' stage and now making simple components that require a bit of thought and require working to dimensions. I need to take a step back and think it through before I do any cutting. The aluminium part I referred to is just a simple hollow eyepiece / telescope adapter of different diameters at either end, I machined one end down to size got a good finish etc, but didn't leave myself much to play with and risked damaging it when I turned it round to do the other end. With hindsight I think I should have used a longer piece and turned the whole thing in one go then parted it off and faced the final end. But I didn't think of that at the time !! Peter

|

| Mike | 12/06/2015 12:21:57 |

713 forum posts 6 photos | Remember, Peter, that someone has to drink the beer out of the can before it can be cut up for packing. Oh, the sacrifices some of us have to make for our model engineering! |

| Gas_mantle. | 12/06/2015 12:50:36 |

359 forum posts 269 photos | Might have to get a case of 10 cans, just in case I need more packing |

| Graham Wharton | 12/06/2015 13:05:39 |

| 149 forum posts 48 photos | Business cards work quite well, often come in a nice little plastic box, and are already a good size for most jobs. can be cut easily into smaller strips as required. I have a box sitting above my lathe from my previous job. Graham

|

| Roger Woollett | 12/06/2015 14:05:16 |

| 148 forum posts 6 photos | I find masking tape works well. Easier than fiddling around with lots of bits of card or shim. Roger Woollett |

| Nigel McBurney 1 | 12/06/2015 14:42:37 |

1101 forum posts 3 photos | Its best to use thicker pieces of packing,either steel,brass or aluminium, around 1.5 mm is ideal, Older 3 jaw chucks i.e. Myford /Burnerd have smooth jaws which barely mark a workpiece,more modern imported chucks tend to have serrations in the jaws ,these will mark the work, If too thin packing is used the jaws will still mark the work, Four jaw chucks can easily mark work as the jaw pressure is higher and steel packing is better. Do not use thin shim, the shim rotating a speed is a very effective cutting machine and can make a mess of fingers, I once saw the results when a colleague was machining a large diameter piece of steel in the 4 jaw of a 8 inch lathe ,the work was protected by thin shim .015in thick and he accidentally cut the tops of all his fingers when his hand got a bit too close, since that day over fifty years ago I have never used thin shim in a lathe chuck. |

| martyn nutland | 13/06/2015 08:59:20 |

| 141 forum posts 10 photos |

Hello Peter I wonder, if you are going to do a lot of work of this kind, and you are clearly a fastidious sort of chap, if it might be worth sending to the chuck maker for a set of soft jaws. I think they would help. I find that the serrated jaws on the chucks we buy these days cut through masking tape when I use it. I find a strip of emery cloth around the work is quite effective as the abrasive surface grips well. Personally, I'm a bit nervous of strips of metal for the same reason as shim is bad news. Good Luck. Martyn

|

| Gas_mantle. | 13/06/2015 09:51:18 |

359 forum posts 269 photos | Hi all, Many thanks for the replies, there's a few ideas there I hadn't thought about. As for a set of soft jaws I was even aware it was possible to buy different jaws, it's certainly something I'll look at. I think at the moment as a beginner a lot of the small snags I'm running into are operator error in not forward thinking things through, sometimes inexperience is making a simple task far for complicated than to needs to be |

| pgk pgk | 13/06/2015 09:56:03 |

| 2661 forum posts 294 photos | Soemwhere orother I;ve seen home made jaw collars held on with a bolt. Aletratively how about u-shpaed pieces of thin bar stock temporarily held with magnets while the wok is setup (then remove magnet to avoid the obvious swarf issue). I've used magnets to temporarily hold parallels against the chuck back while I set work up in the 4-jaw. |

| JasonB | 13/06/2015 10:18:00 |

25215 forum posts 3105 photos 1 articles | 3 slices off some hex ali bored to a snug fit on the ends of the existing chuck jaws work as softjaws. Drill 3 alternate corners for grub screws then use one to hold the new jaw to the old, opposite corner contacts the work. I'm sure they have been in MEW. (Edit 223 has them) Another safer option than a can is to slit a bit of plastic pipe and slip that over the work, Edited By JasonB on 13/06/2015 13:22:12 |

| John Haine | 13/06/2015 10:37:30 |

| 5563 forum posts 322 photos | Gardening shops often sell packets of aluminium strips about 1. X 3 cm used for bending into clips for greenhouse glass. They are 0.5 mm thick and just the job for packing jobs of this sort. |

| Gas_mantle. | 13/06/2015 12:22:29 |

359 forum posts 269 photos | Thanks guys, plenty for me to consider there next time I make the same mistake ! |

| mechman48 | 14/06/2015 12:57:34 |

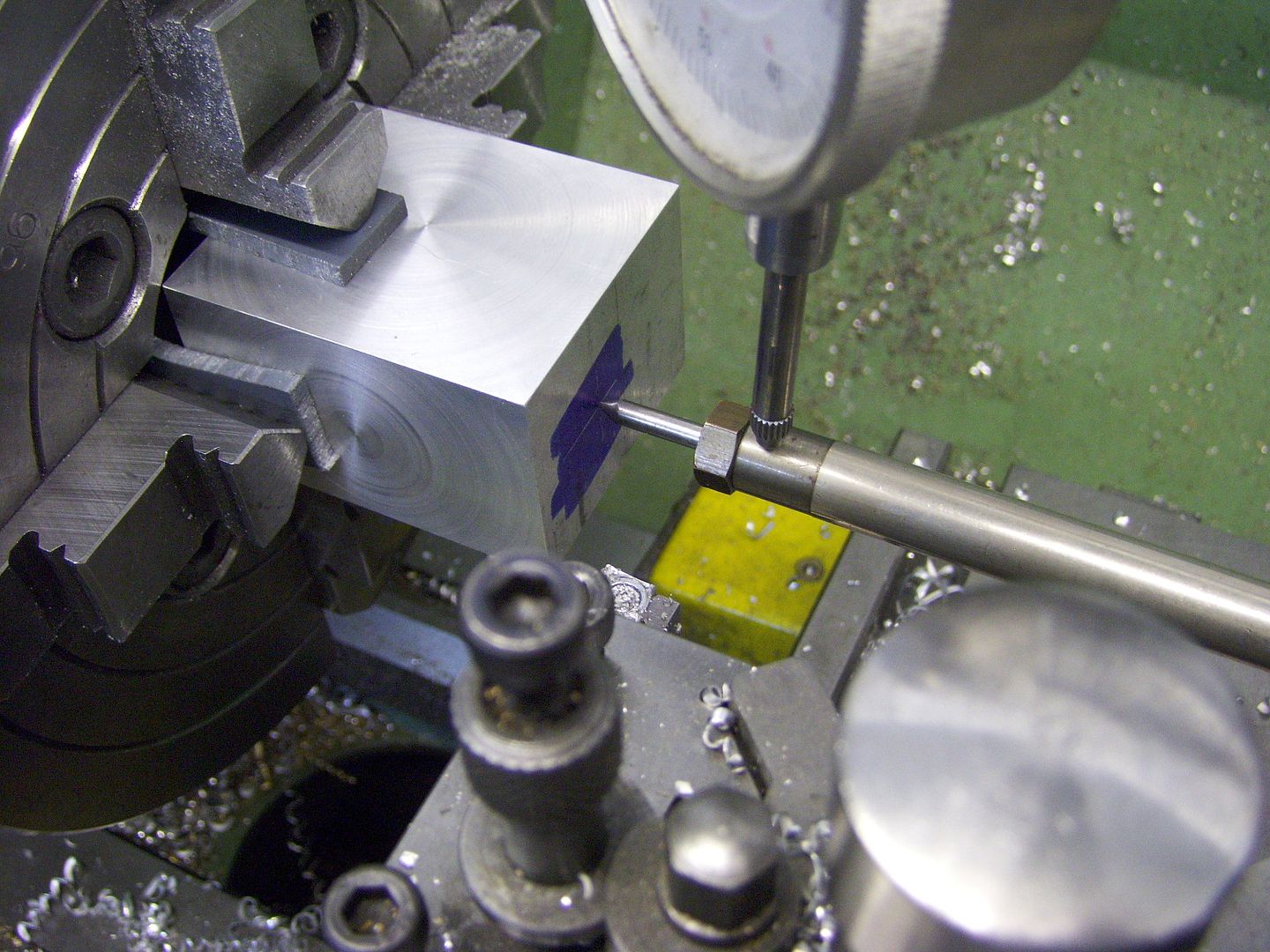

2947 forum posts 468 photos | I made a set of soft jaws... bored out to suit job... George.

|

| Paul Lousick | 14/06/2015 13:27:59 |

| 2276 forum posts 801 photos | Hi George, There may be a problem with your soft jaws. They are clamped at the side and do not press against the location face of the hard jaws and may move when under load.. The soft jaws published in MEW have the screws going thru the peaked corners of the hex nuts. The jaws should be closed tightly to take out any slop before boring the hole. It clamped together the bored hole cannot pass all of the way thru, otherwise an external "spider arrangement" should be used to keep the jaws apart. Paul. Edited By Paul Lousick on 14/06/2015 13:36:44 |

| Ed Duffner | 14/06/2015 15:46:48 |

| 863 forum posts 104 photos | I was trying to figure out how to hold knurled parts for broaching and the previous two picture posts have solved the problem. Thank you Peter for bringing up the question and to the solutions offered. Ed. |

| mechman48 | 14/06/2015 16:40:29 |

2947 forum posts 468 photos | Hi Paul Thanks for your comment, duly noted; the jaws were clamped together & machined square, the lock screws were then tightened, the small hole was then drilled to size required therefore running true to the axis. Have used these on more than one occasion where I've bored out to suit a couple of pieces & so far all has run concentric, to each their own... & they work just fine for me... George |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in