The Workshop Progress Thread (2017)

Report your modeling and workshop progress here

| Gray62 | 14/04/2017 12:45:01 |

| 1058 forum posts 16 photos | Neil, I've used the cheap Rolson ones from Halfords, they are ok and do help relieve the pain in my lower legs when standing for extended periods. The only downside is that hot metal chips do have a tendency to embed into them but they are cheap enough not to worry. I managed to pick up about 50 tiles and edging strip from my local recycling yard for a few quid so I've got a good stock of replacements now. |

| mechman48 | 14/04/2017 12:45:28 |

2947 forum posts 468 photos | I have the interlocking matting from MMart on my garage floor; they are comfy on the feet & alleviate my back probs somewhat, good insulation too, so am satisfied with them, actually looking to get some more as have a couple of gaps where concrete shows, not too pricy if funds are restrictive so would recommend them ( usual discl 'r ) |

| Brian H | 14/04/2017 13:06:57 |

2312 forum posts 112 photos | That all sounds very encouraging, thanks for the replies. The ones I have on order are from ebay item number 291940476587 and are £51.99 for 192 sq ft which will give me a couple of spare pieces. Fortunately, my milling machine is only a small one but it may pay to put a guard around the machine to prevent chips from being embedded in the tiles. Brian |

| Neil Wyatt | 14/04/2017 14:24:32 |

19226 forum posts 749 photos 86 articles | I have a suspended OSB floor, which is a lot more comfortable than supermarkets and shopping malls (which always give me backache!) But I do fancy trying these out, i suppose for a tenner I can't go wrong! Neil

|

| JasonB | 17/04/2017 16:14:38 |

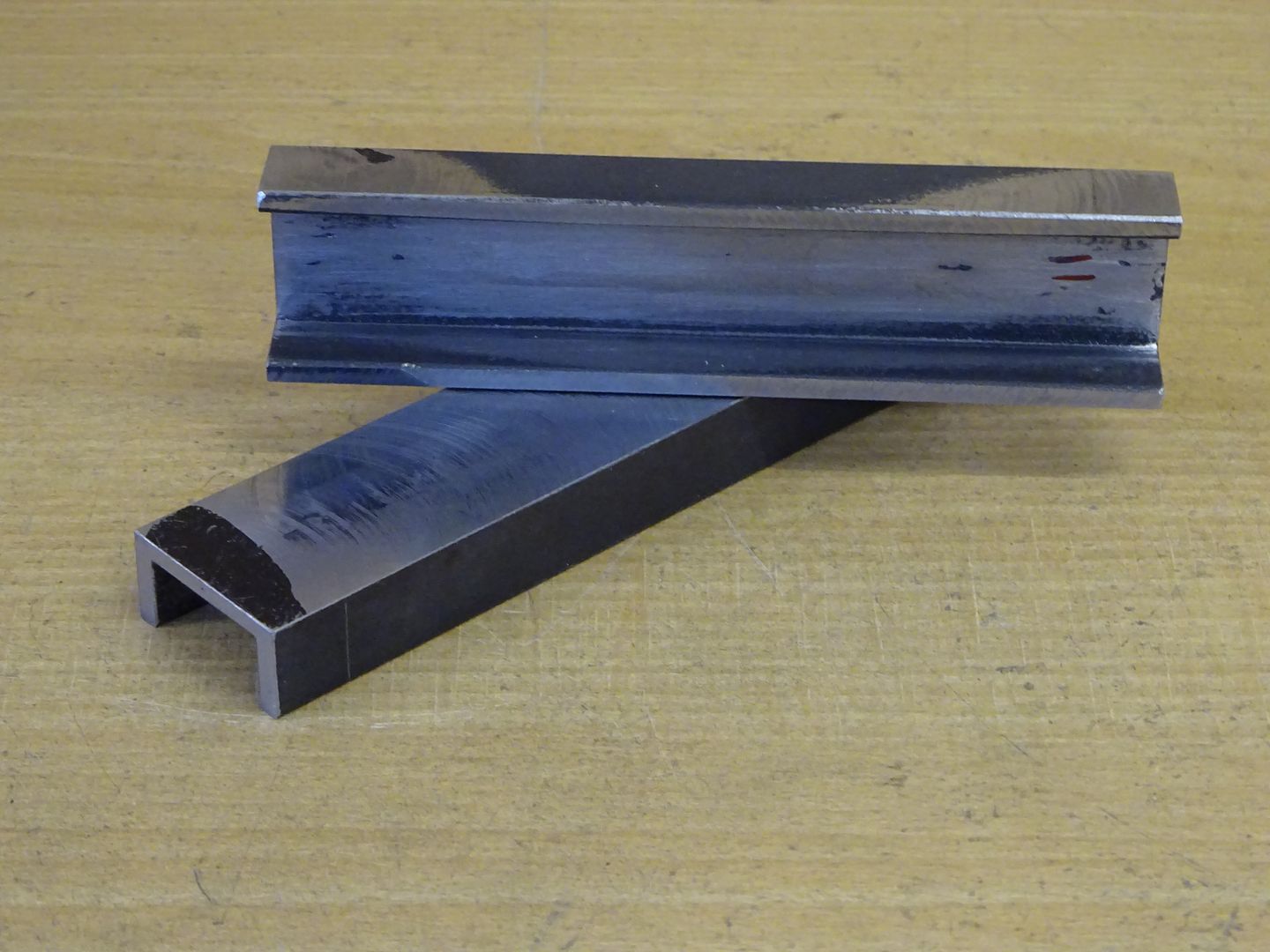

25215 forum posts 3105 photos 1 articles | Not much worth showing on teh R&V but have got several little items crossed off the to do list. On the cart front I welded up a couple of short lengths of angle to make two cross members that will tahe the bolts that hold down the engine base.

Silver soldered on some end plates and notched them out to fit insid ethe two main side rails

Then set about making some of the square headed fixings, mostly all cut from 8mm round bar as that suits the 5.5mm AF I wanted on the M4 threads so the Stevo spin indexer got a good workout.

J

|

| Stuart Bridger | 17/04/2017 20:06:59 |

| 566 forum posts 31 photos | I use the mats available from Machine DRO. Good on the feet and easy to clean. |

| Chris Evans 6 | 17/04/2017 20:16:43 |

2156 forum posts | I bought "Rolson" branded mats when on offer at Halfords. Each 500mm square interlocking and about 14mm thick. I did the whole 17ftx17ft garage for around £100. They are a bit soft and squashy so nice to stand on, the chips don't seem to embed easily but I do sweep up a lot. Downside of them is that they mark with things like motorcycle stands and weight but this tends to be in the same place most of the time. |

| Brian H | 17/04/2017 20:23:43 |

2312 forum posts 112 photos | My mats arrived on Saturday and I've nearly finished laying them. The look good and are very easy on the feet. The only problem is that they crush down under weights. My Austin Seven was parked on them overnight and left tyre impressions this morning. Not a great problem, even corruugated card, which I keep under to catch any oil drips, helps but I think that some pieces of hardboard under the wheels should do the trick. Brian |

| mechman48 | 17/04/2017 23:09:47 |

2947 forum posts 468 photos | |

| mechman48 | 29/04/2017 18:32:02 |

2947 forum posts 468 photos | Machined up the conrod & crosshead for my S50, getting there... |

| JasonB | 29/04/2017 20:01:42 |

25215 forum posts 3105 photos 1 articles | You are getting there George, keep up the good work. |

| mechman48 | 05/05/2017 19:20:57 |

2947 forum posts 468 photos | Machined up the flywheel yesterday... reaming for crankshaft...

|

| mechman48 | 07/05/2017 12:18:16 |

2947 forum posts 468 photos | ... Set up & machined the eccentric & strap, just need to drill & tap for 7BA lock bolt & split, drill for 7BA grub screw in the eccentric. Etch primed cylinder assembly, 1st coated flywheel... clean up & polish... Edited By mechman48 on 07/05/2017 12:19:55 |

| JasonB | 10/05/2017 21:01:01 |

25215 forum posts 3105 photos 1 articles | For a bit of a break from the hit & miss engine carts I knocked this up over the last couple of weeks. About a 2/3rd size replica of the Alyn Foundry "CHUK" flame licker. Will do a build thread with drawings on MEM forum and probably post it here too. With thanks to Graham Corry (Alyn Foundry) and Andy over on MEM. Edited By JasonB on 10/05/2017 21:02:36 |

| Jim Nic | 16/05/2017 20:43:09 |

406 forum posts 235 photos | A little more progress on the Popcorn. The cylinder with its end covers, piston and piston rod

A cylinder family shot, note the extended steam chest to cater for my error in making the cylinder incorrectly with not enough meat on the valve face. I fabricated the steam chest as I didn't have a milling cutter that was long enough to carve out the middle from one side and also small enough to form small radius corners. It is just possible to see the silver solder joins.

And finally the cylinder assembly mounted on a gash bit of aluminium on which I intend to practice engine turning when I get a round tuitt.

I will be making provision for the air/steam inlet to the steam chest a little later in the build when I come to make the inlet manifold. Jim

Edited By Jim Nic on 16/05/2017 20:46:12 |

| Andrew Johnston | 16/05/2017 20:49:37 |

7061 forum posts 719 photos | Neat! Andrew |

| mechman48 | 17/05/2017 11:09:45 |

2947 forum posts 468 photos | I like it1! |

| SillyOldDuffer | 17/05/2017 11:34:19 |

| 10668 forum posts 2415 photos | Wow, Jim and Jason thanks for sharing! |

| mechman48 | 17/05/2017 13:20:41 |

2947 forum posts 468 photos | S50 some more... Edited By mechman48 on 17/05/2017 13:22:13 |

| Jim Nic | 17/05/2017 15:26:17 |

406 forum posts 235 photos | Looking good George. I especially like the connecting rod, beautifully finished. Jim |

This thread is closed.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in