Have You considered getting a 3D printer

NEW POLL

| JasonB | 21/02/2021 10:09:06 |

25215 forum posts 3105 photos 1 articles | Of the posts over the last couple of weeks where people have shown their 3D printed items it is interesting to note that not one was part of the actual finished model. They have been used for holding jigs, patterns, tool holding, tool storage, etc. So really they are being used more as tools than presented as finished items and as the user has designed and printed them I would say more artisan that if they had bought the tools etc. |

| Dave Smith 14 | 21/02/2021 10:46:47 |

| 222 forum posts 48 photos | Jason Some finished parts which are not tooling, although I do use my printers for tooling. Toothbrush holder, not reprinted in white and at 0.1 mm layer Boiler for LNWR crane tank in 4mm scale Replacement nose for rocket on Grandsons toy Bin liner containers for my sons 4mm scale layout Various tests for 5" gauge loco lamps (my own design) Edited By SillyOldDuffer on 21/02/2021 10:51:03 |

| SillyOldDuffer | 21/02/2021 10:48:31 |

| 10668 forum posts 2415 photos | Posted by Martin Kyte on 20/02/2021 23:16:18:

Posted by Bob Stevenson on 01/02/2021 09:16:05:

The really important questions here are; do computer controlled machines have a place in an 'artisan workflow' when making one off, or 'bespoke' items. Parts made on a CNC mill are no longer the product of the hand/eye co-ordination of a crafts person.....does this matter? On that logic an 'artisan workflow' must preclude the use of any machine tools and rely solely on saws, files, hammers and cold chisels for cold working and the forge for welding and hot working. ... I would be perfectly happy to see printed parts in a workshop tool but I'm not sure I would like to see them in the clocks I make. regards Martin ...Fascinating debate, but I think it's more to do with aesthetics and perception than engineering. Nothing wrong with that, I see Leonardo da Vinci's Salvator Mundi sold for $450 million dollars in 2019. I wouldn't want it at any price:

Jeremy Clarkson once remarked the only thing worse than hand-finished was hand-made, but he was talking about super-cars. Ultra expensive, unsuitable for ordinary driving and downright unreliable! The sentiment is however true of most manufactured goods: eliminating hand processes and the need for skills is sure fire way of improving them. Having said that, I do admire and appreciate skilled work of any kind, from clever ideas to brilliant craftwork, meticulous technique or even a neat bodge! There's something very special about individual work whether it's a Renaissance Painting or Brian H's desire to make authentic bulb lubricators for his Ford Quadricycle. I'm frustrated at Exhibitions because there's too much to take in. I'd like to spend at least an hour on almost everything! Nearly all models deserve far more attention than they get, and I suspect the majority of techniques used by Model Engineers are underappreciated unless you've tried them yourself! To me it's the skill that matters, not the particular form it takes, but I have to admit part of the skill is keeping methods and materials appropriate to the particular model. Which is why Martin is right to be wary of 3D printed parts in a traditional clock! Short of being dumped on a desert island there's hardly any way a modern human can avoid using someone else's products. Few of us could make a metal on our own because that technology has been a team game for centuries. Watching Mountain Men on TV, I was struck by the number of chaps proudly living 'off-grid' with metal roofs, double-glazing, firearms, snow-mobiles, petrol generators, power tools, oil-lamps, axes, saws, boots, clothing, plastic piping, wire, nails, buckets, soap and a host of other manufactured items. The reality is they're only slightly less dependent on the rest of the world than I am in rural England. But less likely to catch Covid-19 or have to put up with pesky neighbours! Dave

|

| Martin Kyte | 21/02/2021 10:52:59 |

3445 forum posts 62 photos | Of course it may become increasingly desireable to be able to print coal ;O) Martin |

| TeVe | 21/02/2021 11:37:58 |

22 forum posts 11 photos | Posted by Martin Kyte on 21/02/2021 10:52:59:

Of course it may become increasingly desireable to be able to print coal ;O) Martin Living in Texas? No coal for firing? Then use coke ! Here we wish it could print electricity instead of using it. Edited By TeVe on 21/02/2021 11:39:23 Edited By TeVe on 21/02/2021 11:42:28 |

| Bazyle | 21/02/2021 19:02:01 |

6956 forum posts 229 photos | Posted by JasonB on 21/02/2021 10:09:06:

Of the posts over the last couple of weeks where people have shown their 3D printed items it is interesting to note that not one was part of the actual finished model. Did you mean complete finished model or model part rather than tooling? |

| Neil Wyatt | 22/02/2021 16:22:39 |

19226 forum posts 749 photos 86 articles |

My electric toothbrush lives on top of a 3D printed puck. I just used a peg to fit the charging socket and made the base concave to catch the gunk, which is easily washed off. A good test of the durability of PLA in wet conditions, it's a good few years old. Neil |

| Neil Wyatt | 22/02/2021 16:24:49 |

19226 forum posts 749 photos 86 articles | Posted by Bazyle on 21/02/2021 19:02:01:

Posted by JasonB on 21/02/2021 10:09:06:

Of the posts over the last couple of weeks where people have shown their 3D printed items it is interesting to note that not one was part of the actual finished model. Did you mean complete finished model or model part rather than tooling? Neat. I have a plan to 3D print wheels (and body) for a cement truck. I was going to fit cheap ball races and a tyre from aluminium or steel tube. Neil |

| Oldiron | 22/02/2021 17:37:53 |

| 1193 forum posts 59 photos | My wife keeps asking me if I want a 3D printer for birthday or Xmas. I have not really felt the need for one so I just say no thanks. I think I am too impatient to be bothered with the long wait times for an item to come off the press, so to speak. regards |

| Jeff Dayman | 22/02/2021 19:04:03 |

| 2356 forum posts 47 photos | They have electric toothbrushes now?

When printing on my Ender 3 I usually prep the files in the evening and start the print the following morning after breakfast. For a long print I check it at lunch time and collect it in the evening. For a short print I collect it at lunch time. This method basically lets the machine run lights out and only attended to by a smoke alarm above it and a homemade filament breakage / end of roll detector with a buzzer. This way I invest minimal time attending the machine and also when I do attend it this is done when a mental break is needed in my work day anyway. it helps to switch to 3D print mental thread for a minute rather than the day's toil. (just like machining does, but with cleaner hands!) |

| Brian G | 22/02/2021 19:39:58 |

| 912 forum posts 40 photos | 3D printing doesn't have to be slow. I have never bothered photographing these (NEM coupling adaptors for my son's 00 gauge wagons) but here is the setup on the Chitubox slicer. 32 at a time on the Elegoo Mars build plate take less than two hours to print, wash and cure. Without an injection moulding machine, how else could I have produced them? Perhaps mill some bar to size and then mill the dovetail. Cut into 32 slices, then cut a slot in each of them and solder on a cap to form the socket. All dimensionally accurate to 0.002" and completed in less than two hours - I wish I had that level of skill, but have to accept that I don't. Brian G |

| Bazyle | 23/02/2021 21:41:14 |

6956 forum posts 229 photos | Not sure if you mean a lorry or a railway wagon Neil. |

| Neil Wyatt | 25/02/2021 10:57:48 |

19226 forum posts 749 photos 86 articles | Posted by Bazyle on 23/02/2021 21:41:14:

Not sure if you mean a lorry or a railway wagon Neil. For a 3 1/2" G railway wag(g)on. They will look very much like yours. |

| Journeyman | 25/02/2021 11:30:36 |

1257 forum posts 264 photos | Find my printer useful for workshop improvements. Encouraged by Rod's Post in another thread I decided to re-light the workshop with LED tubes, something I have been meaning to do for ages. Designed brackets and covers using Alibre and printed in PETG. Printing took some time as I replaced 6 old 4' fluorescent fittings, old and noisy, with new 5' LED tubes. So 6 long brackes for the wiring end, 6 short brackets and the matching long and short covers. You can buy batten holders for LEDS but they are pricey compared to a few metres of filament. The LED tubes are quite lightweight so the brackets are only 3mm thick and the covers 2mm. I can now see what I'm doing in the workshop, downside is I can also see that it needs a good cleaning! John |

| Zebethyal | 25/02/2021 15:18:13 |

| 198 forum posts | I built my first printer (a modified Prusa i3) from a set of printed parts and a shelf for less than £100.00 back in 2012, after giving up on my Prusa Mendel and a set of cast parts that I started in 2011. For me it was more about the learning experience and fun of building it than simply buying one and using it - I think it was another 2 years before it was completed and actually printed something.

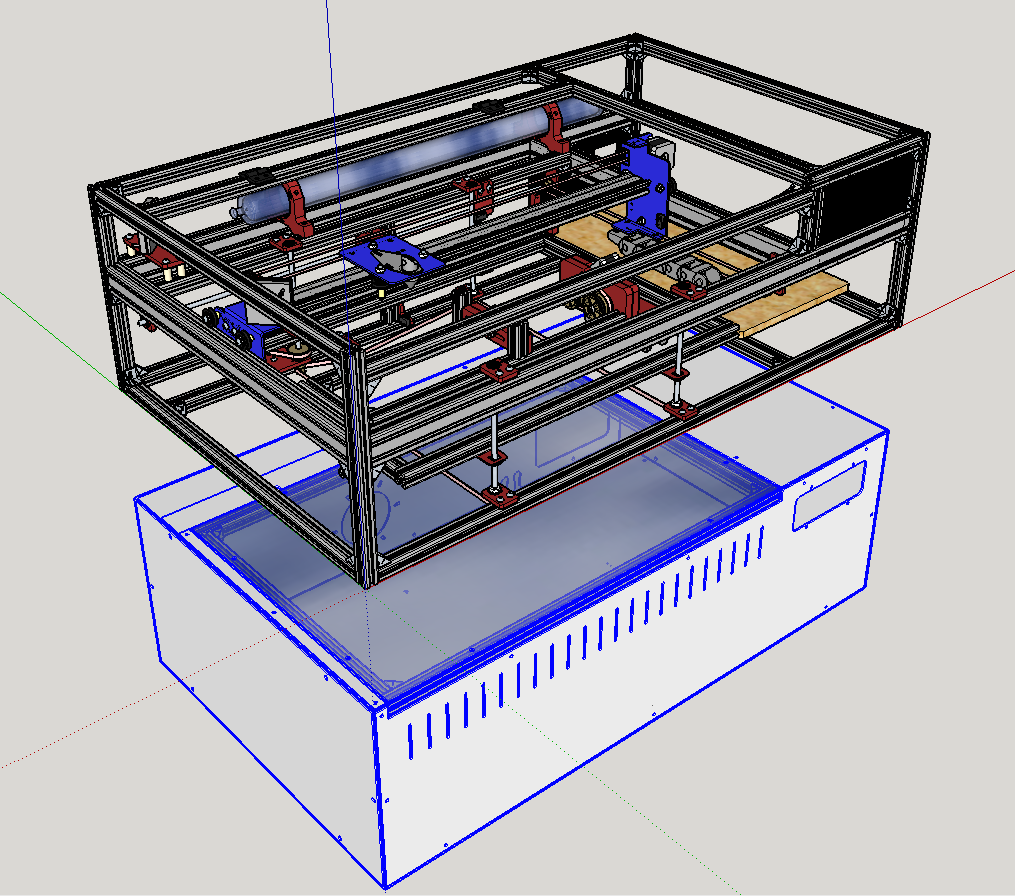

I also heavily modified it over the next few years, using it to print all of the upgrades, as well as many replacement parts when some of the original ones failed (praying the machine would hold together long enough to complete the print). I used it to print all of the parts for my Buildlog 2.x laser cutter, I could have purchased these parts for $75.00 +P&P, I could have machined them from HDPE, or cut them from acrylic with a raw material cost of around £20-30, instead I modelled and printed them for a total cost of around £3.00! I drew the entire laser cutter in Google Sketchup, such that I could guarantee that any additional parts I decided I needed could be designed and known to fit before printing. (I also posted the STL and Sketchup files on GitHub should anyone else want to use them).

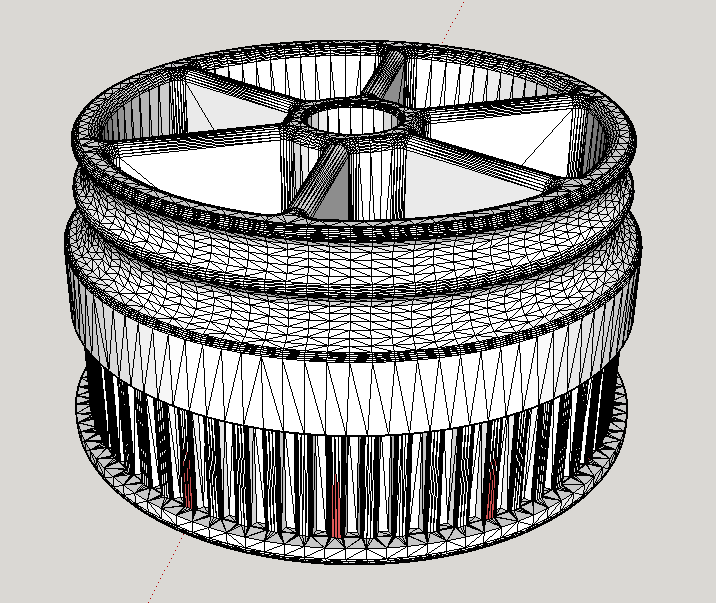

The parts for the rotating axis could mostly have been machined from 12mm HDPE or Acrylic at around £12.00 a sheet, but again I chose to print them for less than £5.00. One of the parts here was a pair of gears that had grooves for a pair of rubber grommets and also a 60 tooth GT2 profile - good luck making these parts by hand or on some manual machinery.

printed part:

Complete rotating axis:

My Prusa i3 eventually fell apart last year (it was mainly made from a sheet of chip board) and I have replaced it with an Ord Bot Hadron, built from a set of aluminium plates and some Makerslide with a total build cost of less than £150.00. The stepper motors I bought for my SX2 CNC conversion had a different screw pattern on the back, so I could not use any of the existing models for covers, so again I designed my own and then added axis information as well.

|

| Oven Man | 25/02/2021 17:15:39 |

204 forum posts 37 photos | I've been using my Sovol SV01 for about two months now and I am generally very pleased with the results I am getting. I am presently building a thread indicator for a Myford Super 7. The top dial on it has some numbers on it and the detail is quite fine. In order to get it to print correctly it looks as if I am going to need to change the nozzle from 0.4mm to 0.2mm. I have purchased a pack of 10 0.2mm nozzles off ebay and just looking at them under a magnifying glass the quality of the actual hole does not look particularly good and is very variable across a number of them. Do the experienced 3D printer users amongst us have any recomendations on where to buy good quality nozzles. There appear to be lots of cheap no brand nozzles for sale and then there is a large price gap up to what appear to be quite high quality ones. Is it worth buying expensive nozzles to go on an entry level printer or do I take pot luck with the cheap ones. There doesn't to be anything that I would consider mid priced. I haven't actually tried the 0.2mm nozzles I have as it's quite a bit of effort to change it. Ant thoughts would be greatfully recieved. Peter |

| Journeyman | 26/02/2021 13:46:07 |

1257 forum posts 264 photos | You could perhaps try ** E3D ** they supply the hotend for the Prusa printers. Haven't used them myself though other than to uy some of their nozzles as spares off Amazon. John |

| Oven Man | 26/02/2021 19:37:07 |

204 forum posts 37 photos | Posted by Journeyman on 26/02/2021 13:46:07:

You could perhaps try ** E3D ** they supply the hotend for the Prusa printers. Haven't used them myself though other than to uy some of their nozzles as spares off Amazon. John Many thanks John. The prices look sensible, and from what I have read they appear to have a good reputation. Will give them a try. Peter |

| Henry Brown | 26/02/2021 19:43:00 |

618 forum posts 122 photos | I can't vouch for this chaps nozzles but his bowden tubs and fittings are very good, I also have his silicone spacers for the build plate. |

| Oven Man | 26/02/2021 21:03:31 |

204 forum posts 37 photos | Posted by Henry Brown on 26/02/2021 19:43:00:

I can't vouch for this chaps nozzles but his bowden tubs and fittings are very good, I also have his silicone spacers for the build plate. Thanks Henry. The nozzles look a reasonable price and certainly worth considering, but I am always a little wary of seller with such a vast range of items for sale, everything from a 3D printer nozzle to a car handbreak push button. I thought at first that he was 3D printing the spare car parts but on closer inspection they look like standard injection moulded parts. Peter |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

_Salvator_Mundi_circa_1500.jpg)

Register

Register Log-in

Log-in